The cost-effectiveness of biofuels is highly conditional and not a simple "yes" or "no." A biofuel’s economic viability hinges entirely on the raw material used, the sophistication of the production technology, the scale of operation, and, most critically, the influence of government subsidies and the fluctuating price of crude oil.

The central challenge is that most first-generation biofuels, like corn ethanol, often struggle to compete with fossil fuels on price alone. Their cost-effectiveness is frequently an outcome of policy decisions rather than pure market economics, while next-generation biofuels offer a path to future competitiveness by avoiding competition with food crops.

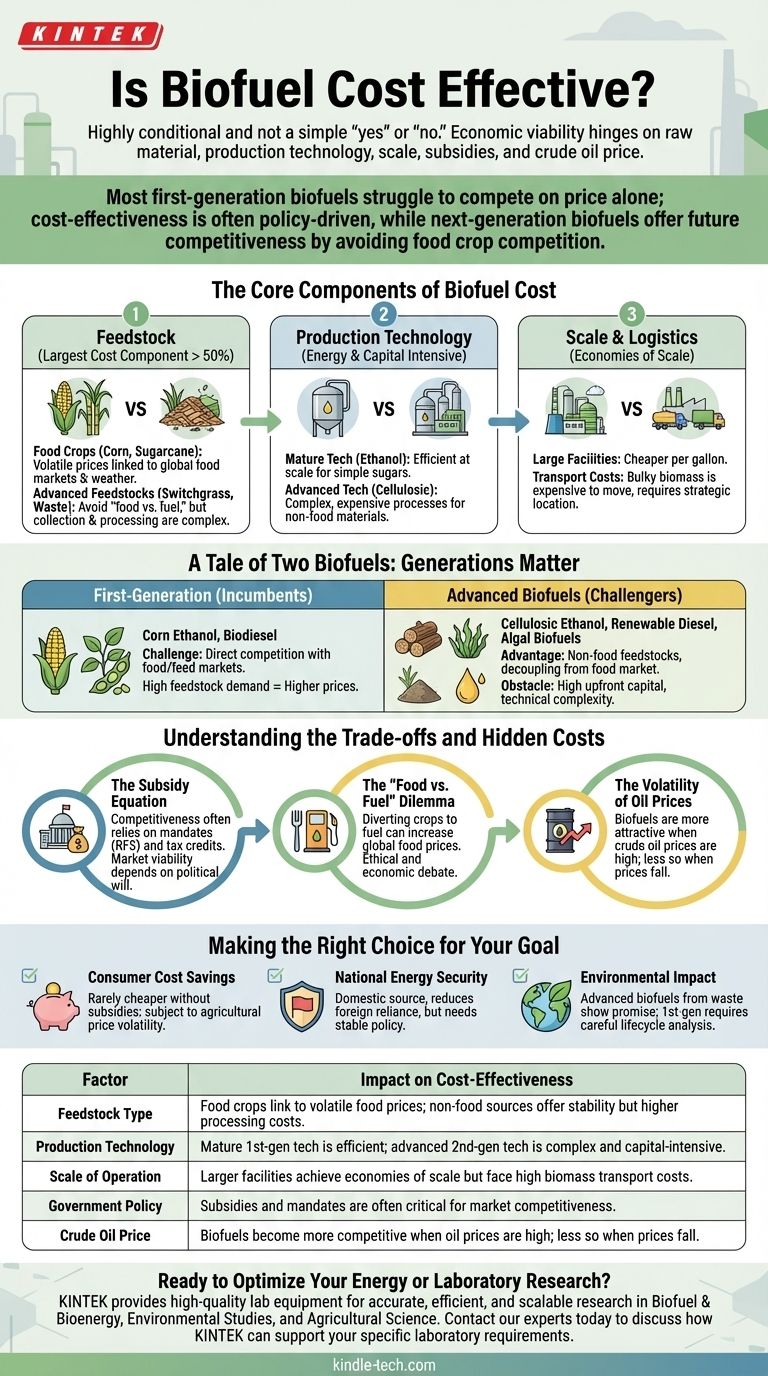

The Core Components of Biofuel Cost

To understand if a biofuel is cost-effective, you must first understand what drives its price. The final cost is a sum of several complex and interconnected factors.

The Critical Role of Feedstock

The feedstock, or raw material, is the single largest cost component in biofuel production, often accounting for over half of the total expense.

The choice of feedstock has massive implications. Using agricultural crops like corn or sugarcane directly links the price of fuel to global food commodity markets, making it volatile and subject to factors like weather and crop yields.

Advanced feedstocks like switchgrass, wood chips, or municipal waste avoid this "food vs. fuel" conflict but can present their own challenges in terms of collection, transportation, and processing consistency.

The Impact of Production Technology

Converting raw biomass into a usable liquid fuel is an energy-intensive and capital-intensive process. The technology used dictates the efficiency and cost of this conversion.

Established technologies, like fermenting corn starch into ethanol, are mature and efficient at scale. However, they only work with simple sugars and starches.

Advanced technologies, such as cellulosic or thermochemical conversion, are required to break down tougher, non-food materials. These processes are currently more complex and expensive, acting as a major barrier to the cost-effectiveness of next-generation biofuels.

The Influence of Scale and Logistics

Like any industrial process, economies of scale are crucial. Large, centralized biorefineries can produce fuel more cheaply per gallon than smaller facilities.

However, biomass is often bulky and has low energy density, making it expensive to transport. The ideal facility must be large enough for efficiency but close enough to its feedstock sources to minimize transportation costs.

A Tale of Two Biofuels: Generations Matter

Not all biofuels are created equal. The distinction between "generations" is fundamental to understanding their different economic profiles.

First-Generation Biofuels (The Incumbents)

These are the most common biofuels today, primarily corn ethanol and soybean-based biodiesel.

Their primary economic challenge is direct competition with food and animal feed markets. When demand for corn or soy is high, feedstock prices rise, and the cost of producing fuel increases accordingly.

Advanced Biofuels (The Challengers)

This category includes cellulosic ethanol (from wood, grasses), renewable diesel (from used cooking oil, animal fats), and algal biofuels.

Their key advantage is the use of non-food feedstocks, which decouples their price from the food market. This offers a path to more stable and potentially lower long-term costs.

The main obstacle is the high upfront capital cost and the technical complexity of their production processes, which are still maturing.

Understanding the Trade-offs and Hidden Costs

A simple comparison of price per gallon at the pump is misleading. The true cost-effectiveness of biofuels involves significant external factors.

The Subsidy Equation

In many markets, including the United States and Brazil, biofuels are only cost-competitive due to government mandates and subsidies.

Policies like the Renewable Fuel Standard (RFS) in the U.S. create artificial demand, while tax credits directly reduce the final cost. This means their market viability is often dependent on political will, not just production efficiency.

The "Food vs. Fuel" Dilemma

The economic and ethical debate over using cropland to produce fuel instead of food is a major hidden cost of first-generation biofuels. Diverting crops to energy production can put upward pressure on global food prices.

The Volatility of Oil Prices

The ultimate benchmark for cost-effectiveness is the price of petroleum. When crude oil is expensive, biofuels appear much more attractive and competitive. When oil prices fall, the economic case for biofuels weakens considerably.

Making the Right Choice for Your Goal

Evaluating biofuel cost-effectiveness depends entirely on your objective.

- If your primary focus is consumer cost savings: Biofuels are rarely cheaper at the pump than gasoline without subsidies and are subject to the volatility of agricultural commodity prices.

- If your primary focus is national energy security: Biofuels provide a domestically produced fuel source that can reduce reliance on foreign oil, but this benefit depends on stable and long-term policy support to be economically sustainable.

- If your primary focus is environmental impact: Advanced biofuels made from waste hold significant promise, while first-generation biofuels require a careful lifecycle analysis to ensure their carbon benefits outweigh the impacts of land use change.

Ultimately, judging the cost of biofuel requires looking beyond the price per gallon to understand the complex interplay of technology, agriculture, and policy.

Summary Table:

| Factor | Impact on Cost-Effectiveness |

|---|---|

| Feedstock Type | Food crops (corn) link to volatile food prices; non-food sources (waste) offer stability but higher processing costs. |

| Production Technology | Mature 1st-gen tech is efficient; advanced 2nd-gen tech is complex and capital-intensive. |

| Scale of Operation | Larger facilities achieve economies of scale but face high biomass transport costs. |

| Government Policy | Subsidies and mandates (e.g., RFS) are often critical for market competitiveness. |

| Crude Oil Price | Biofuels become more competitive when oil prices are high; less so when prices fall. |

Ready to Optimize Your Energy or Laboratory Research?

Navigating the complexities of biofuel production and analysis requires precise and reliable equipment. Whether you are developing next-generation feedstocks or conducting lifecycle analyses, KINTEK provides the high-quality lab equipment and consumables you need for accurate, efficient, and scalable research.

We specialize in serving the precise needs of laboratories focused on:

- Biofuel & Bioenergy Research

- Environmental & Sustainability Studies

- Agricultural Science

Let us help you achieve your research and development goals with confidence. Contact our experts today to discuss how KINTEK can support your specific laboratory requirements.

Visual Guide

Related Products

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant

- Electric Rotary Kiln Continuous Working Small Rotary Furnace Heating Pyrolysis Plant

- Graphite Vacuum Furnace Negative Material Graphitization Furnace

People Also Ask

- Which type of water should be used in water bath for laboratory? Protect Your Equipment and Experiments

- What are the hazards of heat treatment process? Avoid Oxidation, Embrittlement, and Costly Defects

- What is the density of synthetic graphite? Understanding the Range from 1.5 to 2.26 g/cm³

- What is the difference between pyrolysis and catalytic cracking? A Guide to Process Selection

- What are the risks of biomass boilers? Understanding the Environmental and Operational Trade-offs

- What is important to be aware of when working with inert gases? Understanding the Silent Asphyxiation Hazard

- What is the difference between XRF and XRD techniques? A Guide to Choosing the Right Analytical Tool

- What is the Nujol method? A Quick Guide to Solid Sample IR Spectroscopy