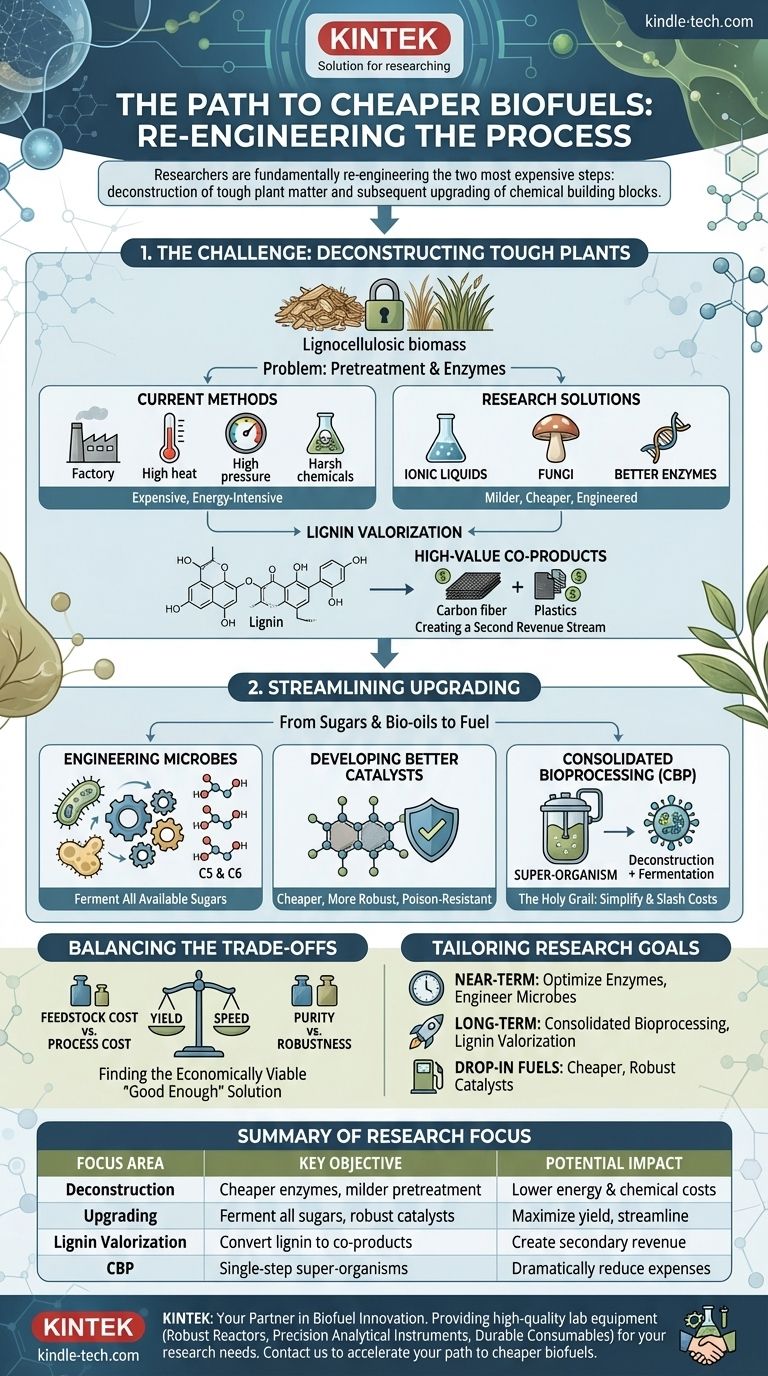

To make biofuels cheaper, researchers are fundamentally re-engineering the two most expensive steps in the production process: the deconstruction of tough plant matter and the subsequent upgrading of the resulting chemical building blocks into finished fuel. The core strategy is to replace costly, energy-intensive physical and chemical methods with more efficient and targeted biological and catalytic solutions.

The central barrier to affordable biofuels is not the cost of the raw plant material, but the difficulty of breaking it down. Therefore, the most critical research aims to dramatically reduce the cost of this "deconstruction" step, primarily by designing better enzymes and microbes to do the work that currently requires harsh chemicals and high energy input.

The Core Challenge: Deconstructing Tough Plants

Advanced biofuels are made from non-food biomass like wood, grasses, and agricultural waste. This material, known as lignocellulose, has a rigid structure designed by nature to resist breakdown. Overcoming this resistance is the first and most expensive hurdle.

The Problem of Pretreatment

Before enzymes can access the valuable sugars in cellulose, the rigid lignocellulose structure must be opened up. This is called pretreatment.

Current methods often use high heat, high pressure, and harsh acids or bases. These processes are expensive due to high energy consumption and the need for corrosion-resistant reactors.

Researchers are developing milder and cheaper pretreatment methods, such as using novel solvents called ionic liquids that can dissolve cellulose at lower temperatures, or using fungi that naturally begin the deconstruction process.

The High Cost of Enzymes

Once pretreated, specialized enzymes are used to break down the long cellulose chains into simple sugars that can be fermented into fuel.

These enzymes are a major operational cost, similar to a recurring raw material expense. A key research goal is to discover or engineer enzymes that are more effective, work faster, and are more resilient to the harsh conditions inside a bioreactor.

Through genetic engineering, scientists are modifying microorganisms to produce these enzymes more cheaply and with higher activity, directly lowering the cost per gallon of fuel.

Unlocking Value from Lignin

Lignocellulose contains another major component called lignin. This complex polymer is often treated as a waste product and simply burned for heat.

A significant research frontier is lignin valorization—finding ways to convert lignin into valuable co-products, such as carbon fiber, plastics, or other industrial chemicals.

By creating a second revenue stream from what was once waste, the overall cost of producing the primary biofuel can be substantially reduced.

Streamlining the Upgrading Process

After deconstruction, the resulting mix of sugars, oils, or gases must be "upgraded" into a finished fuel. This is the second area of intense research focus.

From Sugars to Fuel

In cellulosic ethanol production, the goal is to ferment sugars into alcohol. However, lignocellulose contains two main types of sugars (C5 and C6), and the yeasts traditionally used in brewing can only consume one type.

Scientists are engineering new strains of yeast and bacteria that can efficiently ferment all available sugars, maximizing the fuel yield from the starting biomass and improving the process economics.

Developing Better Catalysts

For producing "drop-in" hydrocarbon fuels like renewable diesel or sustainable aviation fuel, the intermediate sugars or bio-oils are upgraded using catalysts.

These catalysts, often based on precious metals, can be expensive and can be deactivated or "poisoned" by impurities in the bio-oil. Research focuses on creating cheaper, more robust catalysts from earth-abundant metals that can operate for longer without losing effectiveness.

The "Holy Grail": Consolidated Bioprocessing

The most advanced research concept is consolidated bioprocessing (CBP). This involves designing a single "super-organism" or a community of microbes that can perform all steps in one reactor.

This microbe would produce its own enzymes to break down cellulose, and then immediately ferment the resulting sugars into biofuel. By combining deconstruction and upgrading, CBP could eliminate entire stages of the process, dramatically simplifying the plant and slashing capital and operational costs.

Understanding the Trade-offs

Achieving lower costs is not a simple path and involves balancing several competing factors.

Feedstock vs. Process Cost

The cheapest and most abundant biomass sources (e.g., wood chips, corn stover) are often the most difficult and expensive to deconstruct. Researchers must weigh the low cost of the raw material against the high cost of the required technology.

Yield vs. Speed

Some conversion pathways may be very fast but produce a low yield of fuel, while others may achieve high yields but take too long or require too much energy. The optimal solution is a process that is "good enough" on all fronts to be economically viable.

Purity vs. Robustness

Creating a highly pure stream of sugars for fermentation is expensive. Alternatively, developing microbes or catalysts that are robust enough to handle an "impure" mixture of intermediates can be a more cost-effective approach, even if the absolute fuel yield is slightly lower.

Making the Right Choice for Your Goal

The focus of research can be tailored to different strategic objectives for biofuel development.

- If your primary focus is near-term commercialization: Invest in optimizing existing enzyme cocktails and engineering microbes to ferment all sugar types more efficiently.

- If your primary focus is long-term, disruptive cost reduction: Prioritize fundamental research into consolidated bioprocessing and creating high-value co-products from lignin.

- If your primary focus is producing drop-in hydrocarbon fuels: Concentrate on developing cheaper, more poison-resistant catalysts for upgrading bio-oils and syngas.

Ultimately, making advanced biofuels economically competitive hinges on transforming a complex, multi-stage manufacturing process into a streamlined and elegant biological conversion.

Summary Table:

| Research Focus Area | Key Objective | Potential Impact |

|---|---|---|

| Deconstruction | Develop cheaper enzymes & milder pretreatment methods (e.g., ionic liquids) | Lower energy and chemical input costs |

| Upgrading | Engineer microbes to ferment all sugars & create robust catalysts | Maximize fuel yield and streamline production |

| Lignin Valorization | Convert lignin waste into high-value co-products (e.g., carbon fiber, plastics) | Create secondary revenue streams to offset fuel costs |

| Consolidated Bioprocessing (CBP) | Combine deconstruction and upgrading in a single step with "super-organisms" | Dramatically reduce capital and operational expenses |

Ready to Optimize Your Biofuel Research or Production?

As you explore innovative ways to reduce biofuel costs, having the right lab equipment is critical for developing and scaling these advanced processes—from enzyme activity assays to catalyst testing and fermentation studies.

KINTEK specializes in providing high-quality lab equipment and consumables tailored to the needs of biofuel researchers and producers. We understand the precision and reliability required for your work in pretreatment optimization, microbial engineering, and catalytic upgrading.

Partner with us to access:

- Robust Reactors & Fermenters: Designed to handle harsh pretreatment conditions and complex bioprocesses.

- Precision Analytical Instruments: For accurate monitoring of sugar yields, catalyst performance, and fuel purity.

- Durable Consumables: Ensuring consistent results in enzyme assays, microbial cultures, and catalytic reactions.

Let KINTEK be your trusted supplier for the tools that power your biofuel innovations. Contact our experts today to discuss how our solutions can accelerate your path to cheaper, more sustainable biofuels!

Visual Guide

Related Products

- High Performance Laboratory Freeze Dryer

- High Performance Laboratory Freeze Dryer for Research and Development

- Non Consumable Vacuum Arc Induction Melting Furnace

- Custom PTFE Wafer Holders for Lab and Semiconductor Processing

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

People Also Ask

- Why is a freeze dryer considered essential in biological and chemical experiments? Preserve Sample Integrity for Accurate Results

- What is cryogenic grinding of cardamom? Preserve Flavor, Aroma & Color with Extreme Cold

- Why are conventional preservation methods less suitable for biological products? The Critical Risk to Efficacy and Safety

- Why are plate temperature uniformity and flatness important in a freeze dryer? Ensure Product Quality and Process Efficiency

- What is cool grinding technology? Unlock Efficient Milling for Heat-Sensitive Materials