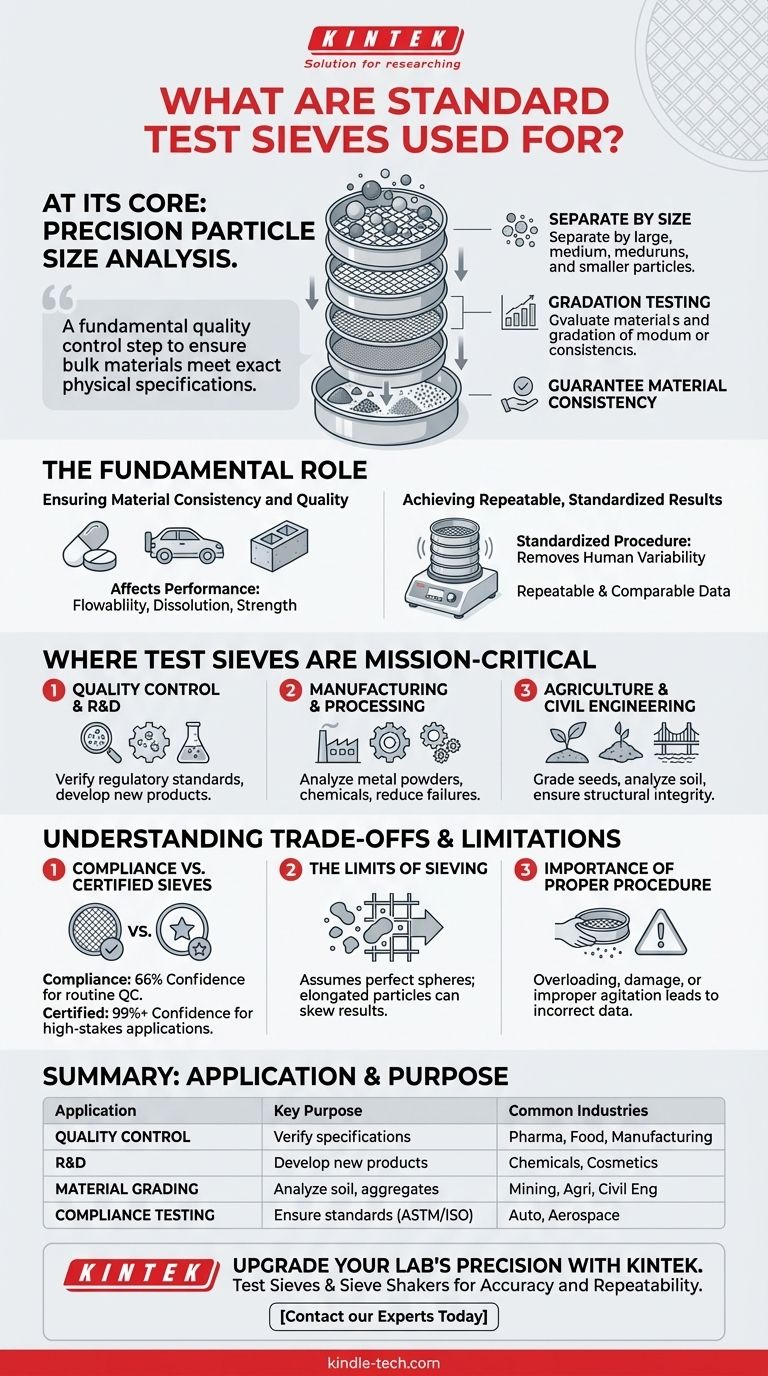

At its core, a standard test sieve is a precision instrument used to separate particles by size. This process, known as particle size analysis or gradation testing, is a fundamental quality control step in industries ranging from pharmaceuticals and food production to mining and agriculture. It ensures that powders, granules, and other bulk materials meet the exact physical specifications required for their intended application.

A test sieve is more than just a screen; it is a foundational tool for guaranteeing material consistency. By accurately measuring the distribution of particle sizes, organizations can control final product quality, predict material behavior, and ensure compliance with industry standards, preventing costly production failures.

The Fundamental Role of Particle Size Analysis

The physical size of particles has a profound impact on a material's behavior, including its flowability, dissolution rate, and compaction. Particle size analysis is the process of quantifying this characteristic to ensure predictability and consistency.

The Sieving Mechanism Explained

The working principle is straightforward. A sample of material is placed on a sieve, which is a woven wire mesh screen with precisely measured, uniform openings. The sieve is agitated, allowing particles smaller than the openings to pass through while retaining larger particles on the mesh.

Often, a stack of sieves with progressively smaller openings is used. This allows the material to be sorted into multiple size fractions simultaneously, providing a detailed particle size distribution profile.

Ensuring Material Consistency and Quality

Consistent particle size is critical for performance. In pharmaceuticals, it affects how quickly a drug dissolves in the body. In manufacturing, it determines the strength and finish of a final product.

By using test sieves to verify the size of incoming raw materials and outgoing products, companies can maintain high quality, reduce variability, and ensure their products perform as expected every time.

Achieving Repeatable, Standardized Results

For results to be reliable, the procedure must be standardized. Modern laboratory sieve shakers provide controls for vibration amplitude and duration. This removes human variability from the agitation process, ensuring that tests are repeatable and comparable across different batches, labs, and operators.

Where Test Sieves are Mission-Critical

Test sieves are used across a vast range of industries where particle characteristics are a key performance indicator.

Quality Control and R&D

In laboratory and quality inspection settings, sieves are used to verify that materials meet internal or regulatory standards. In research and development, they are essential for developing new products and understanding how particle size affects performance.

Manufacturing and Processing

Industries like automotive, aerospace, and pharmaceuticals rely on sieves to analyze materials for everything from metal powders to chemical agents. This analysis leads to higher-quality components and fewer internal product failures.

Agriculture and Civil Engineering

In agriculture, sieves are used to grade seeds and analyze soil composition, which impacts drainage and crop growth. In mining and construction, they are used to analyze soil, sand, and gravel to ensure the structural integrity of foundations and concrete mixtures.

Understanding the Trade-offs and Limitations

While powerful, test sieves are tools that must be used correctly. Understanding their limitations is key to generating accurate data.

"Compliance" vs. "Certified" Sieves

Most standard test sieves are compliance sieves. They are manufactured to meet ASTM or ISO standards with a statistical confidence level of 66%. This is sufficient for most routine quality control applications.

For high-stakes applications or instances requiring irrefutable proof of accuracy, certified sieves are available. These are measured more extensively to provide a 99% or higher confidence level, but come at a significant cost premium.

The Limits of Sieving

Sieving assumes particles are perfect spheres, but they are often not. Elongated or flat particles may pass through openings diagonally, skewing the results. This is an inherent limitation of the mechanical sorting process.

The Importance of Proper Procedure

The accuracy of a sieve analysis depends entirely on the method. Overloading a sieve with too much sample, using a damaged or warped mesh, or improper agitation will all lead to incorrect and unreliable data. The tool is only as good as the technician using it.

Applying This to Your Goal

Your specific need will determine the right approach to sieve testing.

- If your primary focus is routine production quality control: Standard compliance-grade sieves are typically sufficient for ensuring materials fall within an acceptable size range.

- If your primary focus is formal research and development: A sieve shaker with precise timer and amplitude controls is crucial for achieving the repeatable, standardized data needed for analysis.

- If your primary focus is meeting strict regulatory or contractual standards: You may need to invest in certified sieves that offer a higher statistical confidence level for aperture size.

Ultimately, using the correct test sieve methodology transforms material assessment from a guess into a precise, data-driven science.

Summary Table:

| Application | Key Purpose | Common Industries |

|---|---|---|

| Quality Control | Verify material meets size specifications | Pharmaceuticals, Food, Manufacturing |

| R&D | Develop new products and understand material behavior | Chemicals, Cosmetics |

| Material Grading | Analyze soil, sand, and aggregates | Mining, Agriculture, Civil Engineering |

| Compliance Testing | Ensure adherence to industry standards (ASTM/ISO) | Automotive, Aerospace |

Upgrade your lab's precision with KINTEK's test sieves and sieve shakers. Whether you're in pharmaceuticals, food production, or materials science, our equipment delivers the accuracy and repeatability you need for reliable particle size analysis. Contact our experts today to find the perfect solution for your quality control and R&D requirements!

Visual Guide

Related Products

- Laboratory Ball Mill Jar Mill with Metal Alloy Grinding Jar and Balls

- Laboratory Four-Body Horizontal Jar Mill

- Stainless Steel Laboratory Ball Mill for Dry Powder and Liquid with Ceramic Polyurethane Lining

- Small Lab Rubber Calendering Machine

- Laboratory Vibratory Sieve Shaker Machine Slap Vibrating Sieve

People Also Ask

- What is sieving filtering? Master the Key Differences for Accurate Material Separation

- Why is the sieve test important? The Key to Quality Control and Product Consistency

- What is the use of Laboratory sieve? Achieve Precise Particle Size Analysis for Quality Control

- What is the maximum sieving deviation permitted? A Guide to ASTM & ISO Precision Limits

- How do you measure particle size distribution? Match the Right Technique to Your Material

- What is the name of the sieve test? Unlock Material Secrets with Sieve Analysis

- Are different sieves used to separate different mixtures? Choose the Right Sieve for Your Mixture

- What is an example of sieving in the laboratory? Master Particle Size Analysis for Quality Control