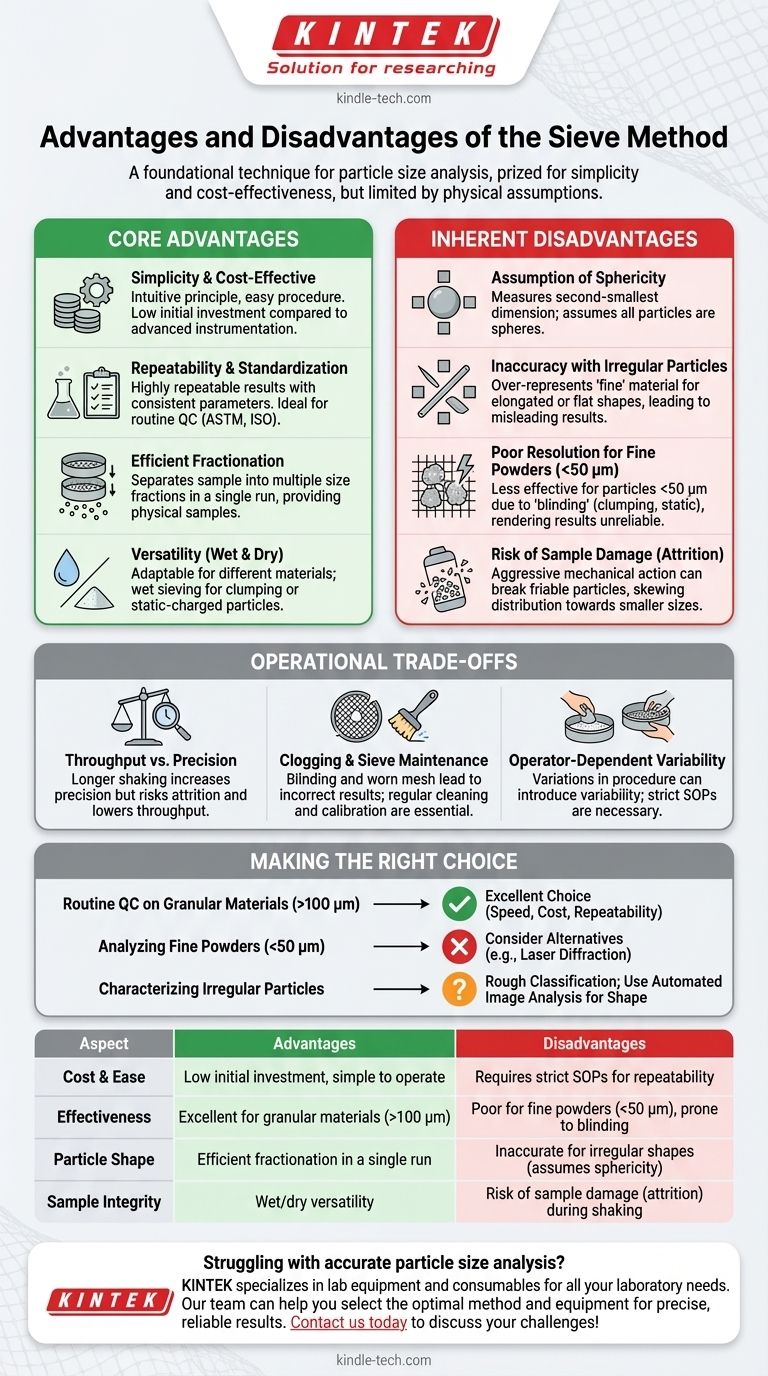

At its core, the sieve method is a foundational technique for particle size analysis, prized for its simplicity and cost-effectiveness. Its primary advantages are speed, repeatability for standardized processes, and the ability to physically separate material into different size fractions. However, its fundamental disadvantages stem from the physical assumption that all particles are spheres, leading to significant inaccuracies with fine powders and irregularly shaped materials.

Sieve analysis is an indispensable tool for routine quality control of larger, granular materials. Its value diminishes significantly when high accuracy is required for particles smaller than 50 microns or for materials with non-spherical shapes, where alternative methods become necessary.

The Core Advantages of Sieve Analysis

Sieving remains a dominant method in many industries for several practical reasons. Its benefits are centered on efficiency, cost, and standardization.

Simplicity and Cost-Effectiveness

The principle of sieving is intuitive and the procedure is easy to learn. The initial investment in a set of certified sieves and a mechanical shaker is significantly lower than that for more advanced instrumentation like laser diffraction analyzers.

Repeatability and Standardization

For a given set of parameters—shaking time, amplitude, and sample mass—sieve analysis provides highly repeatable results. This makes it an ideal method for routine quality control where consistency is more critical than absolute accuracy. Many industries (such as construction, food, and pharmaceuticals) have official standards (e.g., ASTM, ISO) built around sieve analysis results.

Efficient Fractionation in a Single Run

Using a stack of sieves with progressively smaller mesh openings allows a sample to be separated into multiple size fractions in a single test. This is incredibly efficient and provides a physical sample of each fraction for further inspection or use.

Versatility for Wet and Dry Methods

The sieve method can be adapted for different material types. While dry sieving is most common, wet sieving can be used for materials that tend to clump together or have significant static charge, ensuring particles separate and pass through the apertures properly.

The Inherent Disadvantages and Limitations

The method's physical nature is also the source of its primary weaknesses. These limitations are critical to understand before choosing it for a specific application.

The Assumption of Sphericity

Sieve analysis measures the second-smallest dimension of a particle—the one that determines if it can pass through a square hole. The entire method implicitly assumes particles are spheres, but in reality, most materials are not.

Inaccuracy with Irregular Particles

This is the direct consequence of the sphericity assumption. An elongated or flat particle (like a fiber or a flake) can pass through a mesh opening end-on or diagonally, even if its overall length or surface area is much larger. This leads to a mass-based result that over-represents the amount of "fine" material, which can be highly misleading.

Poor Resolution for Fine Powders

Sieving becomes progressively less effective for particles smaller than approximately 50 micrometers (µm), or around 300 mesh. At this scale, forces like static electricity and moisture cause particles to clump together, preventing them from passing through the mesh. This phenomenon, known as blinding, renders the results unreliable.

Risk of Sample Damage (Attrition)

The aggressive mechanical action of a sieve shaker can cause brittle or friable particles to break down during the test. This process, called attrition, creates more fine particles than were present in the original sample, skewing the distribution towards smaller sizes.

Understanding the Operational Trade-offs

Beyond the theoretical pros and cons, practical challenges arise during day-to-day use that impact the reliability of your results.

Throughput vs. Precision

A longer shaking time can help ensure more particles find an opportunity to pass through the mesh, potentially increasing accuracy. However, this also increases the risk of particle attrition and lowers the overall sample throughput of the lab.

Clogging and Sieve Maintenance

If not operated correctly, sieves can become permanently clogged (blinding) or the mesh can be distorted. A damaged or worn sieve will produce incorrect results. Regular inspection, cleaning, and calibration or replacement are essential for maintaining data integrity.

Operator-Dependent Variability

While the method is simple, variations in sample loading, shaker settings, and cleaning procedures between different operators can introduce variability into the results. Strict adherence to a Standard Operating Procedure (SOP) is necessary to ensure repeatability.

Making the Right Choice for Your Application

Ultimately, whether sieving is the right method depends entirely on your material and your goal.

- If your primary focus is routine QC on granular materials (>100 µm): Sieving is an excellent choice for its speed, low cost, and high repeatability in a production environment.

- If your primary focus is analyzing fine powders (<50 µm): You must consider alternative methods like laser diffraction, as sieving will not provide the accuracy or resolution required.

- If your primary focus is characterizing irregularly shaped particles (e.g., fibers, flakes): Sieving can provide a rough dimensional classification, but a method like automated image analysis is necessary to understand the true particle shape and size.

Choosing the correct particle analysis method requires a clear understanding of what you are truly trying to measure.

Summary Table:

| Aspect | Advantages | Disadvantages |

|---|---|---|

| Cost & Ease | Low initial investment, simple to operate | Requires strict SOPs for repeatability |

| Effectiveness | Excellent for granular materials (>100 µm) | Poor for fine powders (<50 µm), prone to blinding |

| Particle Shape | Efficient fractionation in a single run | Inaccurate for irregular shapes (assumes sphericity) |

| Sample Integrity | Wet/dry versatility | Risk of sample damage (attrition) during shaking |

Struggling with accurate particle size analysis? KINTEK specializes in lab equipment and consumables for all your laboratory needs. Whether you're performing routine QC on granular materials or require advanced analysis for fine powders, we have the right tools and expertise. Our team can help you select the optimal method and equipment to ensure precise, reliable results for your specific application. Contact us today to discuss your particle analysis challenges and discover how KINTEK can enhance your lab's efficiency and data integrity!

Visual Guide

Related Products

- Laboratory Test Sieves and Vibratory Sieve Shaker Machine

- Three-dimensional electromagnetic sieving instrument

- Laboratory Wet Three-Dimensional Vibratory Sieve Shaker Machine

- Laboratory Vibratory Sieve Shaker Machine Slap Vibrating Sieve

- Custom PTFE Teflon Parts Manufacturer for PTFE Mesh F4 Sieve

People Also Ask

- Why is a laboratory electromagnetic vibratory sieve shaker used? Optimize Walnut Shell Chemical Pretreatment

- Why is a standardized sieving system necessary for elephant grass research? Ensure Reliable Sample Consistency

- How do high-precision sieving systems benefit zeolite preparation? Maximize Adsorption for Wastewater Treatment

- Why is powder classification using standard sieves essential for SHS reactions? Unlock Superior Nitriding Results

- Why is a laboratory sieving system required for bentonite in coatings? Ensure Flawless Surface Performance