The primary advantage of a wiped film evaporator is its ability to gently distill highly sensitive materials that would be destroyed by traditional methods. By combining a high vacuum, a short residence time, and the mechanical agitation of a thin film, it enables the purification of heat-sensitive, viscous, and high-boiling-point compounds with exceptional efficiency and minimal thermal degradation.

At its core, a wiped film evaporator solves the problem of thermal decomposition. It separates molecules based on their volatility at temperatures far below their normal boiling points, making it the ideal tool for purifying valuable materials that cannot tolerate prolonged heat exposure.

How Wiped Film Evaporation Solves a Fundamental Problem

Traditional distillation requires a material to be heated at length, which can damage or destroy complex molecules. Wiped film evaporation, also known as thin-film distillation, is engineered specifically to overcome this challenge.

Minimizing Thermal Degradation

The most critical advantage is an extremely short residence time. The material is exposed to the heated surface for only a matter of seconds.

This brief exposure is insufficient for most heat-sensitive compounds, like those found in pharmaceuticals or specialty oils, to decompose.

Enabling Low-Temperature Distillation

Wiped film systems operate under a deep vacuum. Lowering the pressure dramatically lowers a substance's boiling point.

This allows for the evaporation of large molecules at significantly reduced temperatures, sometimes hundreds of degrees below their atmospheric boiling point, preserving their chemical integrity.

Handling Viscous and Fouling Materials

The internal wipers are a key mechanical advantage. They continuously spread the feed material into a thin, turbulent film against the heated wall.

This action ensures even heating and prevents fouling or charring, which is a common problem when distilling thick, viscous, or slurry-like substances in static systems. The wipers keep the material moving and the heat transfer surface clean.

Key Operating Principles Explained

The unique advantages of a wiped film system stem directly from its sophisticated design, where each component serves a specific purpose in enabling gentle separation.

The Role of the Thin Film

By spreading the material into a thin layer, the system dramatically increases the surface-area-to-volume ratio.

This maximized surface area allows for incredibly rapid and efficient heat transfer, which in turn leads to instantaneous evaporation of the target compounds.

The Wipers' Dual Function

The wipers perform two jobs simultaneously. First, they create and maintain the thin film.

Second, they introduce turbulence into the film, which constantly renews the surface layer and significantly improves both heat and mass transfer efficiency, driving volatile molecules away from the liquid.

The Internal Condenser

In a specific configuration known as short path distillation, the condenser is placed inside the evaporator body, just centimeters from the heated wall.

This short travel path prevents the evaporated molecules from colliding with each other and re-condensing before reaching the collection surface, which is essential for maintaining a deep vacuum and achieving high-purity separation in a single pass.

Understanding the Trade-offs

While powerful, wiped film technology is not universally applicable. Its specialized nature comes with specific considerations that make it unsuitable for certain applications.

Higher Capital Cost

These systems are mechanically complex, involving precision-engineered rotating parts, vacuum systems, and robust seals.

Consequently, the initial investment for a wiped film evaporator is significantly higher than for simpler batch distillation setups like a rotary evaporator or a simple boiling flask.

Mechanical Complexity and Maintenance

The presence of moving parts—the wiper basket, motor, and vacuum seals—introduces potential points of failure.

These components require regular maintenance and eventual replacement, adding to the long-term operational cost and complexity compared to static distillation apparatus.

Throughput Limitations for Bulk Chemicals

While highly efficient for high-value products, wiped film systems are generally not designed for the massive throughput required in bulk commodity chemical production.

For separating millions of gallons of simple solvents, other technologies like falling film or fractional distillation columns are often more economical at scale.

When to Choose a Wiped Film Evaporator

Selecting this technology depends entirely on the nature of your material and your final goal. It is a precision tool for challenging separations.

- If your primary focus is preserving heat-sensitive compounds: A wiped film system is the superior choice due to its combination of low-temperature operation and minimal heat exposure time.

- If your primary focus is processing viscous or fouling materials: The mechanical action of the wipers makes it one of the only viable methods for continuous distillation without clogging or degradation.

- If your primary focus is achieving the highest purity of a high-boiling-point oil in a single pass: The short-path design operating under deep vacuum provides unparalleled separation efficiency for these applications.

Ultimately, wiped film evaporation unlocks the ability to purify materials that were previously considered undistillable.

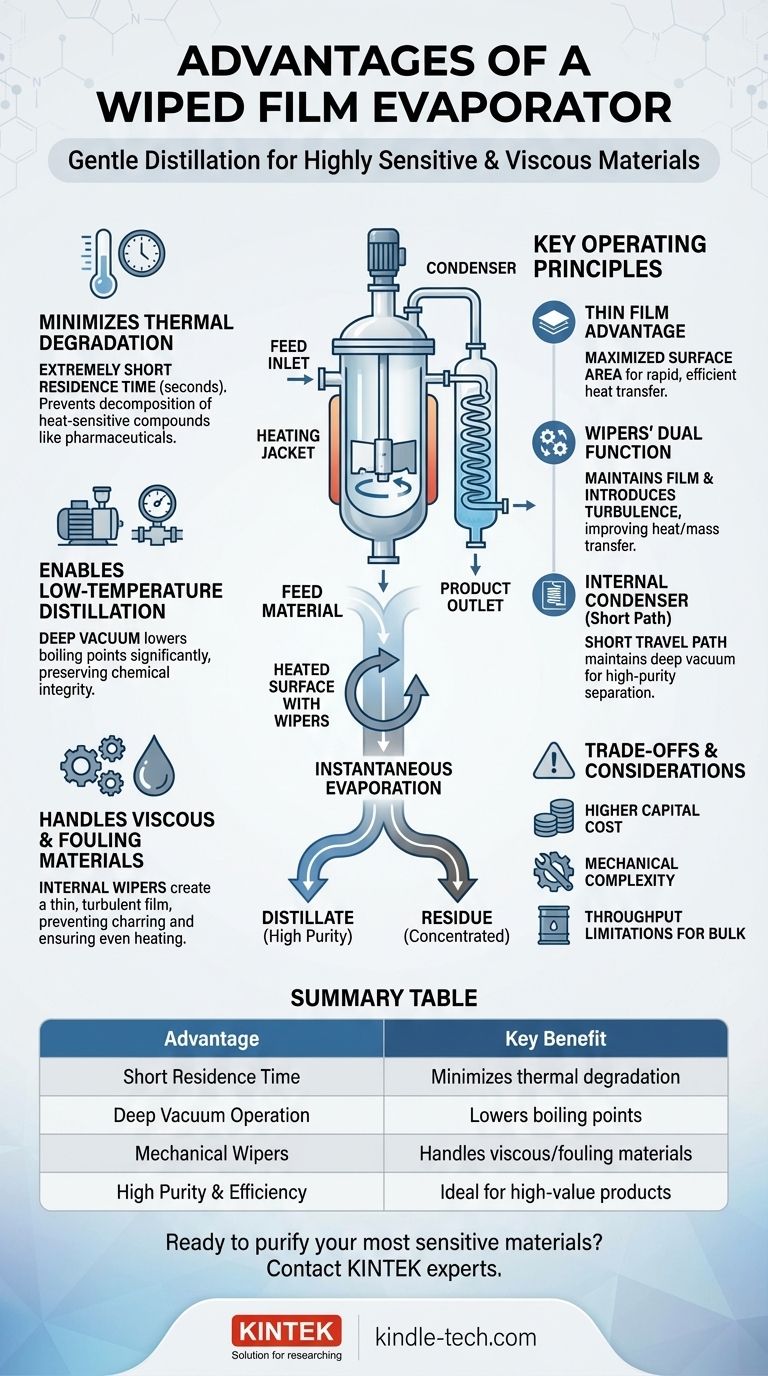

Summary Table:

| Advantage | Key Benefit |

|---|---|

| Short Residence Time | Minimizes thermal degradation of sensitive materials. |

| Deep Vacuum Operation | Lowers boiling points, enabling low-temperature distillation. |

| Mechanical Wipers | Handles viscous materials, prevents fouling, and ensures even heating. |

| High Purity & Efficiency | Ideal for high-value products like pharmaceuticals and specialty oils. |

Ready to purify your most sensitive materials?

If you're working with heat-sensitive compounds, viscous oils, or high-boiling-point substances, a KINTEK wiped film evaporator can provide the gentle, efficient separation you need. Our lab equipment is designed to handle your toughest purification challenges while preserving product integrity.

Contact our experts today to discuss how our wiped film evaporators can enhance your laboratory's capabilities and protect your valuable products.

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Evaporation Crucible for Organic Matter

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- E Beam Crucibles Electron Gun Beam Crucible for Evaporation

People Also Ask

- What is plasma activated chemical vapour deposition method? A Low-Temperature Solution for Advanced Coatings

- Why does PECVD commonly use RF power input? For Precise Low-Temperature Thin Film Deposition

- How does PECVD work? Enable Low-Temperature, High-Quality Thin Film Deposition

- What are the applications of PECVD? Essential for Semiconductors, MEMS, and Solar Cells

- How does RF power create plasma? Achieve Stable, High-Density Plasma for Your Applications