At its core, a ball mill’s primary advantage is its ability to reliably produce extremely fine powders from hard, abrasive materials. It achieves this through a simple, robust design that allows for both wet and dry grinding, making it a versatile workhorse across industries like ceramics, mining, and pharmaceuticals. Its enclosed system also provides superior containment for processing toxic or sterile substances.

The true value of a ball mill lies not in its speed, but in its methodical effectiveness. Its simple design leverages the powerful forces of impact and attrition to deliver consistent, ultra-fine particle reduction for a wide range of challenging materials.

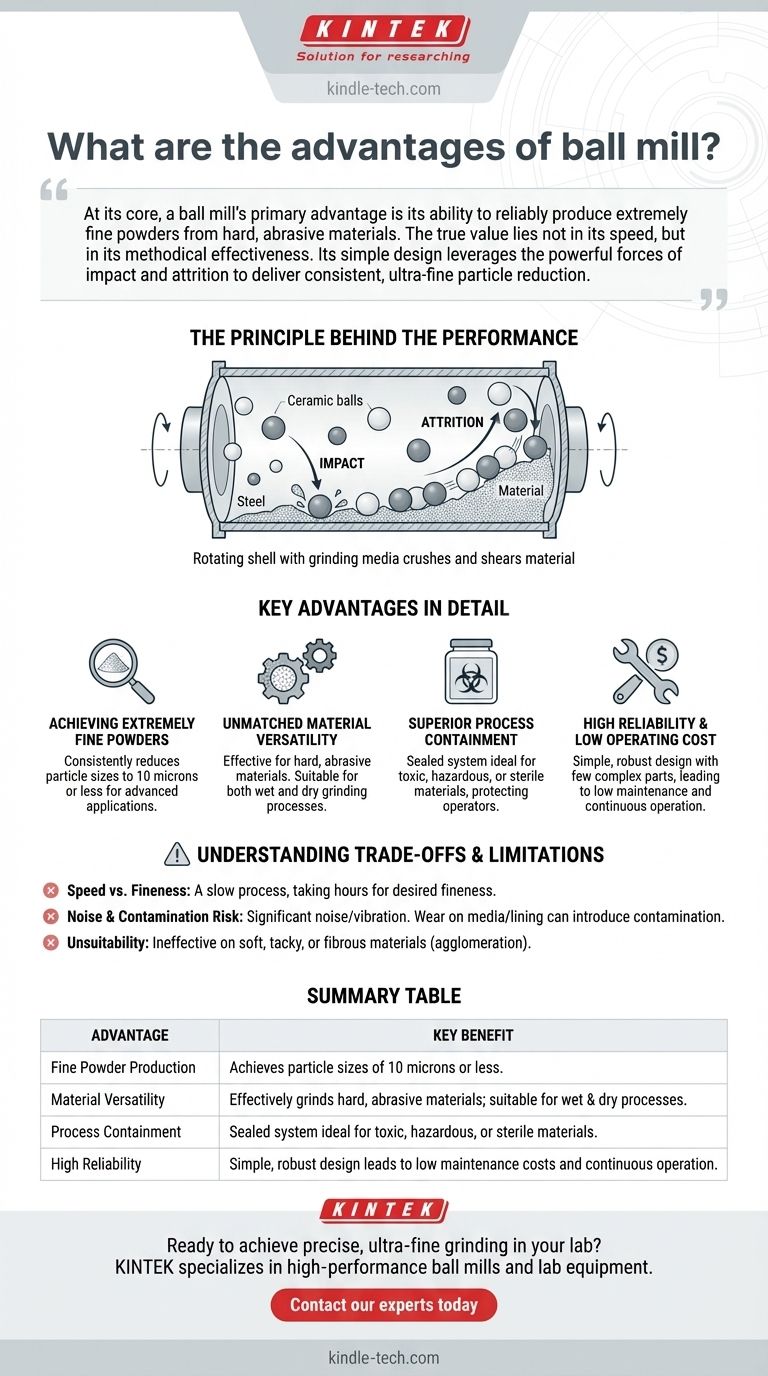

The Principle Behind the Performance

A ball mill is a type of grinder that uses a rotating cylindrical shell partially filled with grinding media, typically ceramic or steel balls. The material to be ground is added to the shell, and as it rotates, the media cascades and tumbles, grinding the material.

The Power of Impact and Attrition

The size reduction occurs through two primary mechanisms. Impact happens when the grinding balls drop from the top of the rotating shell, crushing the particles below. Attrition occurs as the balls rub against each other and the inner surface of the cylinder, shearing and grinding the material.

A Simple and Robust Design

This straightforward mechanism requires few complex parts, making the ball mill exceptionally reliable and simple to service. Its effectiveness is determined by factors like rotation speed, ball size and density, and the duration of the milling process.

Key Advantages in Detail

The ball mill's design directly translates into several significant operational advantages that make it a preferred choice for specific applications.

Achieving Extremely Fine Powders

The most cited advantage is the ability to produce a very fine powder. The continuous, high-energy collisions can consistently reduce particle sizes to 10 microns or less, a level of fineness required for many advanced material applications.

Unmatched Material Versatility

Ball mills are highly effective for grinding hard and abrasive materials that would quickly wear out other types of grinders. Furthermore, they are suitable for both wet and dry grinding processes, adding to their operational flexibility.

Superior Process Containment

Because the grinding takes place inside a sealed container, ball mills are ideal for processing toxic or hazardous materials without exposing operators or the environment. This same principle allows for maintaining sterility, which is critical in manufacturing pharmaceutical products like injectables and eye drops.

High Reliability and Low Operating Cost

The simple design leads to high reliability and low maintenance costs. They can be set up for continuous operation, and with periodic replenishment of the grinding media to compensate for wear, they can maintain a prescribed milling fineness over very long periods.

Understanding the Trade-offs and Limitations

No technology is perfect, and the ball mill's strengths come with inherent trade-offs. Understanding these is critical for making an informed decision.

Speed vs. Fineness

The primary disadvantage is that ball milling is a slow process. Achieving the desired level of fineness can take several hours, making it less suitable for applications where high throughput is the absolute priority.

Noise and Contamination Risk

Ball mills generate significant noise and vibration during operation. More critically, the constant impact and attrition cause wear on both the grinding media and the cylinder lining. This wear can introduce small amounts of contamination into the milled product, a crucial consideration for high-purity applications.

Unsuitability for Certain Materials

The crushing and grinding action is ineffective on soft, tacky, or fibrous materials. These substances tend to agglomerate or coat the grinding media rather than breaking down, making the ball mill the wrong tool for the job.

Is a Ball Mill Right for Your Process?

Choosing the right milling technology depends entirely on your material properties and production goals.

- If your primary focus is achieving the finest possible powder from hard materials: The ball mill is an industry standard and one of the most effective tools available.

- If you are processing hazardous, oxygen-sensitive, or sterile materials: The enclosed design provides a critical safety and purity advantage that few other methods can match.

- If your most critical factor is processing speed and high throughput: You should evaluate faster grinding methods, accepting that you may sacrifice some particle fineness.

- If you are milling soft, fibrous, or heat-sensitive substances: A ball mill is likely unsuitable, and you should explore alternative technologies like cutter or pin mills.

By understanding these core strengths and limitations, you can confidently determine if the ball mill's reliable and precise grinding power aligns with your specific industrial needs.

Summary Table:

| Advantage | Key Benefit |

|---|---|

| Fine Powder Production | Achieves particle sizes of 10 microns or less. |

| Material Versatility | Effectively grinds hard, abrasive materials; suitable for wet & dry processes. |

| Process Containment | Sealed system ideal for toxic, hazardous, or sterile materials. |

| High Reliability | Simple, robust design leads to low maintenance costs and continuous operation. |

Ready to achieve precise, ultra-fine grinding in your lab? KINTEK specializes in high-performance ball mills and lab equipment, delivering the reliability and containment your processes demand. Whether you're in ceramics, mining, or pharmaceuticals, our solutions are designed to meet your specific material challenges. Contact our experts today to find the perfect ball mill for your application!

Visual Guide

Related Products

- Laboratory Single Horizontal Jar Mill

- High-Energy Omnidirectional Planetary Ball Mill Milling Machine for Laboratory

- High-Energy Omnidirectional Planetary Ball Mill Machine for Laboratory

- High Energy Planetary Ball Mill Milling Machine for Laboratory

- High Energy Planetary Ball Mill Milling Machine for Laboratory

People Also Ask

- What is the ball mill based on the principle of? Impact and Attrition for Efficient Grinding

- Why use zirconia ball milling jars for SiC/ZTA composite powders? Ensure High Purity & Efficient Particle Refinement

- Why are excellent sealing and corrosion resistance required for WC-10Co ball milling? Ensure High-Purity Mixing Results

- How do stainless steel grinding jars and balls contribute to mechanical alloying? Optimize HEA Powder Synthesis

- Why are silicon nitride or zirconia preferred for milling iodo-vanadate-lead precursors? Ensure High Purity Results