At its core, ball milling is a powerful and versatile mechanical process used to grind materials into fine powders and induce structural changes. Its main advantages are its ability to achieve significant particle size reduction, its applicability to a wide range of materials, and its capacity for creating novel alloys and material phases without melting.

The true advantage of ball milling lies not in a single function, but in its adaptability. By modifying the process—such as using cryogenic temperatures or high-frequency vibration—it can be precisely tailored to achieve outcomes ranging from simple grinding to the synthesis of advanced nanomaterials with high purity.

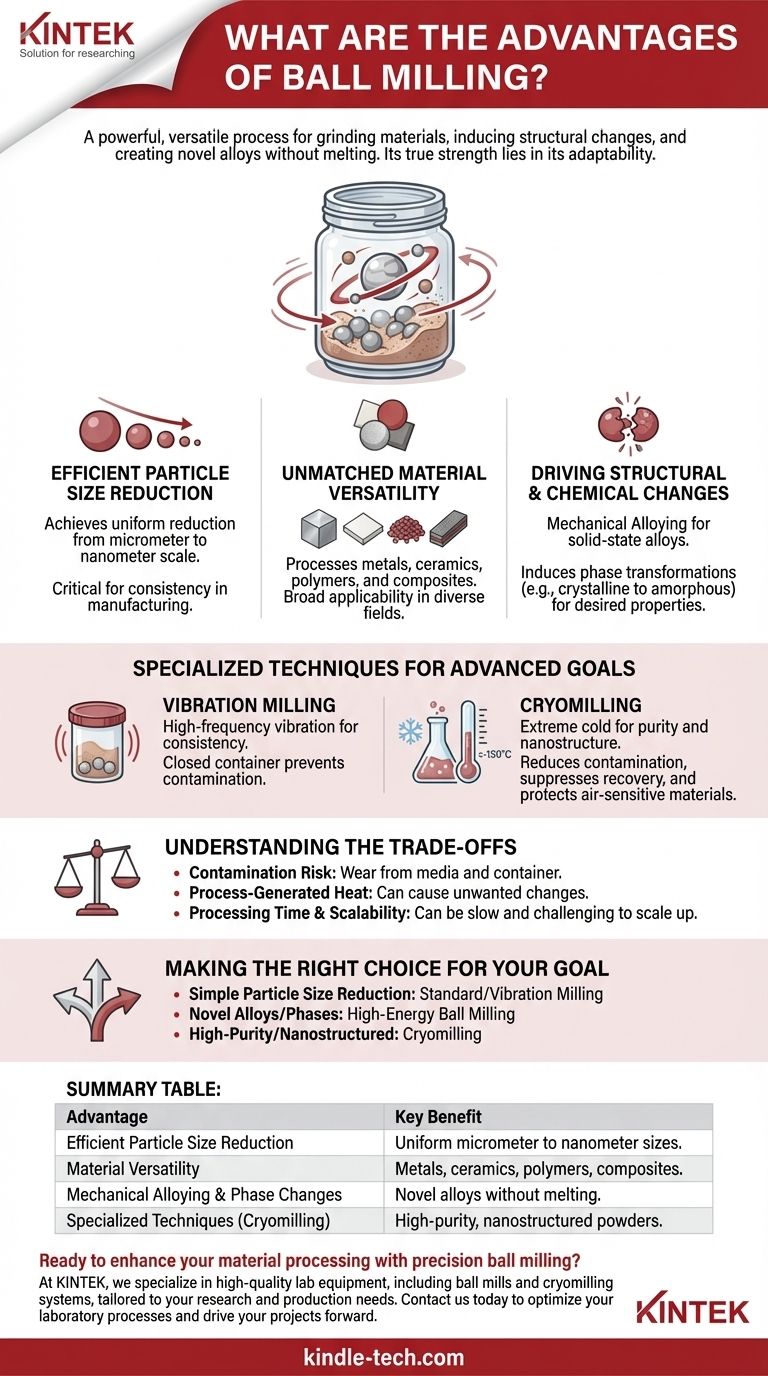

How Ball Milling Delivers Results

The fundamental principle of ball milling is the repeated transfer of high-impact mechanical energy. Materials are placed in a container with grinding media (balls), and the container is rotated or vibrated, causing the balls to collide with and crush the material.

Efficient Particle Size Reduction

Ball milling is exceptionally effective at breaking down coarse materials. The intense, repeated impacts and shear forces can reduce particle sizes from the micrometer scale all the way down to the nanometer scale.

This process ensures a highly uniform particle size distribution, which is critical for consistency in subsequent manufacturing or research applications.

Unmatched Material Versatility

One of the technique's greatest strengths is its broad applicability. It is not limited to a single class of material.

Ball milling can be successfully used to process metals, ceramics, polymers, and composites, making it a go-to method in fields ranging from metallurgy to pharmaceuticals.

Driving Structural and Chemical Changes

The mechanical energy is so intense that it can do more than just grind; it can change the material itself. This process, known as mechanical alloying, can create solid-state alloys by repeatedly fracturing and cold-welding particles together.

It can also be used to induce phase transformations, turning a material's crystalline structure into an amorphous one, or vice-versa, to achieve desired properties.

Specialized Milling Techniques for Advanced Goals

Standard ball milling is a workhorse, but specialized variations unlock unique advantages for more sensitive or demanding applications.

Vibration Milling for Consistency

In vibration milling, the container is vibrated at high frequency, leading to more frequent and less random impacts compared to simple rotation. This results in highly efficient grinding and a very uniform final particle size.

Because the process takes place in a closed container, it effectively prevents contamination from external sources like the atmosphere.

Cryomilling for Purity and Nanostructure Control

Cryomilling is ball milling performed at cryogenic temperatures (below -150°C), typically using liquid nitrogen or argon. This extreme cold provides several distinct advantages.

It makes materials more brittle, accelerating particle size reduction. This speed means less wear on the milling tools, resulting in lower contamination from the milling media itself.

The cold temperatures also suppress material recovery and recrystallization, allowing for the formation of extremely fine nanostructures that would be unstable at room temperature.

Finally, cryomilling protects air-sensitive materials from oxidation and nitridation, preserving their chemical integrity. Using liquid argon is particularly effective for avoiding the nitrogen contamination that can occur when using liquid nitrogen.

Understanding the Trade-offs

While powerful, ball milling is not without its challenges. Objectively considering these limitations is key to using the technique successfully.

The Inherent Risk of Contamination

Although a closed container prevents external contamination, the grinding media and container walls themselves can wear down. This wear can introduce small amounts of impurities (e.g., iron, chrome, tungsten) into your powder, which is a critical consideration for high-purity applications.

Managing Process-Generated Heat

The immense mechanical energy of milling is converted into heat. For temperature-sensitive materials, this can cause unwanted changes like phase transitions or decomposition. While cryomilling is the direct solution, it adds complexity and cost to the process.

Processing Time and Scalability

Achieving nano-scale particles or full alloying can be a very slow process, sometimes requiring many hours or even days of continuous milling. Scaling the process up from a lab-sized batch to industrial production can also present significant engineering challenges.

Making the Right Choice for Your Goal

To leverage ball milling effectively, match the technique to your specific objective.

- If your primary focus is simple particle size reduction for robust materials: Standard planetary or vibration milling offers a cost-effective and efficient solution.

- If your primary focus is creating novel alloys or amorphous phases: High-energy ball milling is necessary to provide the required mechanical energy for structural transformation.

- If your primary focus is producing high-purity, nanostructured, or air-sensitive powders: Cryomilling is the superior choice, as it minimizes contamination and unwanted chemical reactions while enabling ultra-fine grain structures.

By understanding these core principles and variations, you can select the precise ball milling technique to achieve your material engineering goals.

Summary Table:

| Advantage | Key Benefit |

|---|---|

| Efficient Particle Size Reduction | Achieves uniform particle sizes from micrometer to nanometer scale. |

| Material Versatility | Processes metals, ceramics, polymers, and composites. |

| Mechanical Alloying & Phase Changes | Creates novel alloys and amorphous/crystalline phases without melting. |

| Specialized Techniques (Cryomilling) | Enables high-purity, nanostructured powders with minimal contamination. |

Ready to enhance your material processing with precision ball milling?

At KINTEK, we specialize in providing high-quality lab equipment, including ball mills and cryomilling systems, tailored to meet your specific research and production needs. Whether you are developing novel alloys, producing high-purity nanomaterials, or simply require efficient particle size reduction, our expertise ensures you achieve consistent, reliable results.

Contact us today to discuss how our solutions can optimize your laboratory processes and drive your projects forward. Get in touch with our experts now!

Visual Guide

Related Products

- High Energy Planetary Ball Mill Machine for Laboratory Horizontal Tank Type

- High-Energy Omnidirectional Planetary Ball Mill Milling Machine for Laboratory

- High-Energy Omnidirectional Planetary Ball Mill Machine for Laboratory

- High Energy Planetary Ball Mill Milling Machine for Laboratory

- High Energy Planetary Ball Mill Milling Machine for Laboratory

People Also Ask

- How does a planetary high-energy ball mill contribute to the top-down preparation of layered materials? Optimize Yield

- Why are high-intensity planetary ball mills preferred for reducing the crystallinity of lignocellulose?

- How does a planetary ball mill enhance the electrocatalytic activity of La0.6Sr0.4CoO3-δ? Boost Your Catalyst Performance

- What role does a planetary ball mill play in SHS? Optimize Powder Activation for Superior Alloy Synthesis

- What is the specific role of a high-energy planetary ball mill in the synthesis of Ag-doped sulfide solid-state electrolytes?