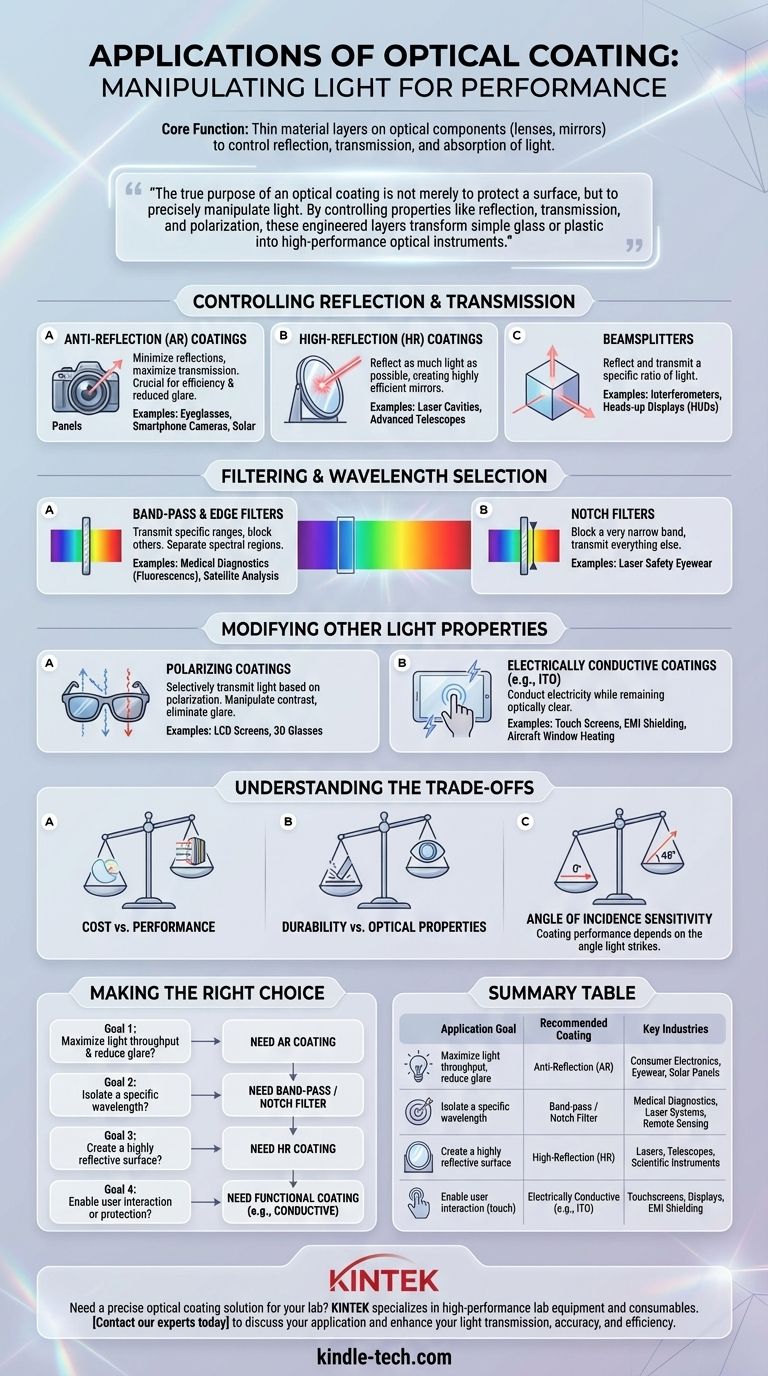

At its core, an optical coating is a series of thin material layers applied to an optical component, like a lens or mirror, to change the way it reflects, transmits, or absorbs light. These coatings are indispensable across a vast range of industries, from consumer eyeglasses and smartphone cameras to advanced laser systems, medical diagnostic equipment, and aerospace technology. Their application determines the precise function of the optical component itself.

The true purpose of an optical coating is not merely to protect a surface, but to precisely manipulate light. By controlling properties like reflection, transmission, and polarization, these engineered layers transform simple glass or plastic into high-performance optical instruments.

Controlling Reflection and Transmission

The most common function of optical coatings is to manage how much light passes through a surface versus how much bounces off. This fundamental control is the basis for many modern optical technologies.

Anti-Reflection (AR) Coatings

AR coatings are designed to minimize reflections from a surface, thereby maximizing light transmission. This is crucial for improving efficiency and reducing unwanted glare.

These coatings are ubiquitous in camera lenses, eyeglasses, solar panels, and display screens on devices like smartphones and laptops, where clarity and brightness are paramount.

High-Reflection (HR) Coatings

Conversely, HR coatings are designed to reflect as much light as possible, creating highly efficient mirrors. These are often made from layers of dielectric materials.

Their primary application is in laser cavities, where light must be bounced back and forth with minimal loss, and in advanced telescopes and scientific instruments requiring precise light management.

Beamsplitters

Beamsplitter coatings strike a balance, designed to both reflect and transmit a specific ratio of light. A 50/50 beamsplitter, for example, will reflect half the light and let the other half pass through.

They are essential components in interferometers for precision measurement, heads-up displays (HUDs) in cars and aircraft, and teleprompters.

Filtering and Wavelength Selection

Many advanced applications depend on isolating or blocking specific colors—or wavelengths—of light. This is accomplished with highly specialized interference filters.

Band-pass and Edge Filters

Band-pass filters transmit a specific range of wavelengths while blocking all others. Edge filters (long-pass or short-pass) separate light into two broad spectral regions.

These are critical in medical diagnostics (like fluorescence microscopy), remote sensing satellites that analyze specific atmospheric gases, and machine vision systems.

Notch Filters

A notch filter is the opposite of a band-pass filter; it blocks a very narrow band of wavelengths while transmitting everything else.

The most common application is in laser safety eyewear, which is designed to block the specific wavelength of a dangerous laser while allowing the user to see their surroundings clearly.

Modifying Other Light Properties

Beyond simple reflection and transmission, coatings can alter other fundamental characteristics of light or add entirely new functionalities to a surface.

Polarizing Coatings

These coatings selectively transmit light based on its polarization state. They are essential for manipulating contrast and eliminating specific types of glare.

You find them in LCD screens, polarized sunglasses, 3D movie glasses, and specialized filters for photography and scientific imaging.

Electrically Conductive Coatings

Transparent conductive coatings, like Indium Tin Oxide (ITO), conduct electricity while remaining optically clear.

This unique property is the foundation for modern touch screens. They are also used for EMI shielding on sensitive electronics and for heating elements on aircraft windows to prevent icing.

Understanding the Trade-offs

Optical coatings are a solution born of compromise. Selecting the right one requires balancing performance, durability, and cost.

Cost vs. Performance

The complexity of a coating dictates its price. A simple single-layer AR coating is relatively inexpensive, while a multi-layer filter with extremely sharp wavelength cutoffs can be exceptionally costly due to tight manufacturing tolerances.

Durability vs. Optical Properties

A coating's resilience to abrasion, temperature, and humidity is critical. Hard, durable coatings may not always offer the absolute best optical performance, forcing a trade-off based on the intended operating environment.

Angle of Incidence Sensitivity

The performance of many advanced coatings, particularly interference filters, is highly dependent on the angle at which light strikes the surface. A filter designed for normal incidence may not work at all at a 45-degree angle.

Making the Right Choice for Your Goal

The application you have in mind directly determines the type of coating required. Your goal should be the primary driver of your selection.

- If your primary focus is maximizing light throughput and reducing glare: You need an Anti-Reflection (AR) coating, the standard for all imaging lenses and display screens.

- If your primary focus is isolating a specific wavelength of light: You need a band-pass or notch filter, which is critical for scientific analysis, medical diagnostics, and laser systems.

- If your primary focus is creating a highly reflective surface: You need a High-Reflection (HR) coating, the enabling technology for modern mirrors in lasers and telescopes.

- If your primary focus is enabling user interaction or environmental protection: You need a functional coating like a transparent conductor (for touch) or a hydrophobic layer (for durability).

Ultimately, optical coatings are the invisible technology that enables the performance of nearly every advanced optical system we use today.

Summary Table:

| Application Goal | Recommended Coating Type | Key Industries |

|---|---|---|

| Maximize light throughput, reduce glare | Anti-Reflection (AR) | Consumer Electronics, Eyewear, Solar Panels |

| Isolate a specific wavelength of light | Band-pass / Notch Filter | Medical Diagnostics, Laser Systems, Remote Sensing |

| Create a highly reflective surface | High-Reflection (HR) | Lasers, Telescopes, Scientific Instruments |

| Enable user interaction (touch) | Electrically Conductive (e.g., ITO) | Touchscreens, Displays, EMI Shielding |

Need a precise optical coating solution for your lab equipment or instrument? At KINTEK, we specialize in high-performance lab equipment and consumables, including custom optical components. Our expertise ensures you get the right coating to enhance light transmission, improve accuracy, and boost the efficiency of your laboratory systems. Contact our experts today to discuss your specific application and discover how we can support your research and development goals.

Visual Guide

Related Products

- Shortpass Filters for Optical Applications

- Narrow Band Pass Filters for Precision Applications

- Longpass Highpass Filters for Optical Applications

- Custom PTFE Teflon Parts Manufacturer for Sampling Filters

- Boron Nitride (BN) Crucible for Phosphorous Powder Sintered

People Also Ask

- What are the four main types of sensors? A Guide to Power Source and Signal Type

- Why use 0.25 μm PTFE filters after centrifugation? Master Clarification for High-Turbidity Samples

- What is the lifespan of a filter media? Understand the 3 Types for Optimal Filtration

- What are the factors that affect the filtration of the solution? Master the Key Variables for Optimal Performance

- What are the advantages of using PTFE filters for ionic component analysis? Ensure Accurate Sample Quantification