In a ball mill, there is no single, universal ball size. Instead, the optimal size is a calculated decision based primarily on the size of the material you are grinding (the feed) and the diameter of the mill itself. Grinding media typically ranges from as small as 12mm (about 0.5 inches) for fine grinding to as large as 125mm (about 5 inches) for breaking down coarse primary crusher output.

The core principle is to match the energy of the grinding media to the material being broken. Large, heavy balls provide the high-impact energy needed to break large feed particles, while a greater number of small balls provides the surface area required for efficient, fine grinding through attrition.

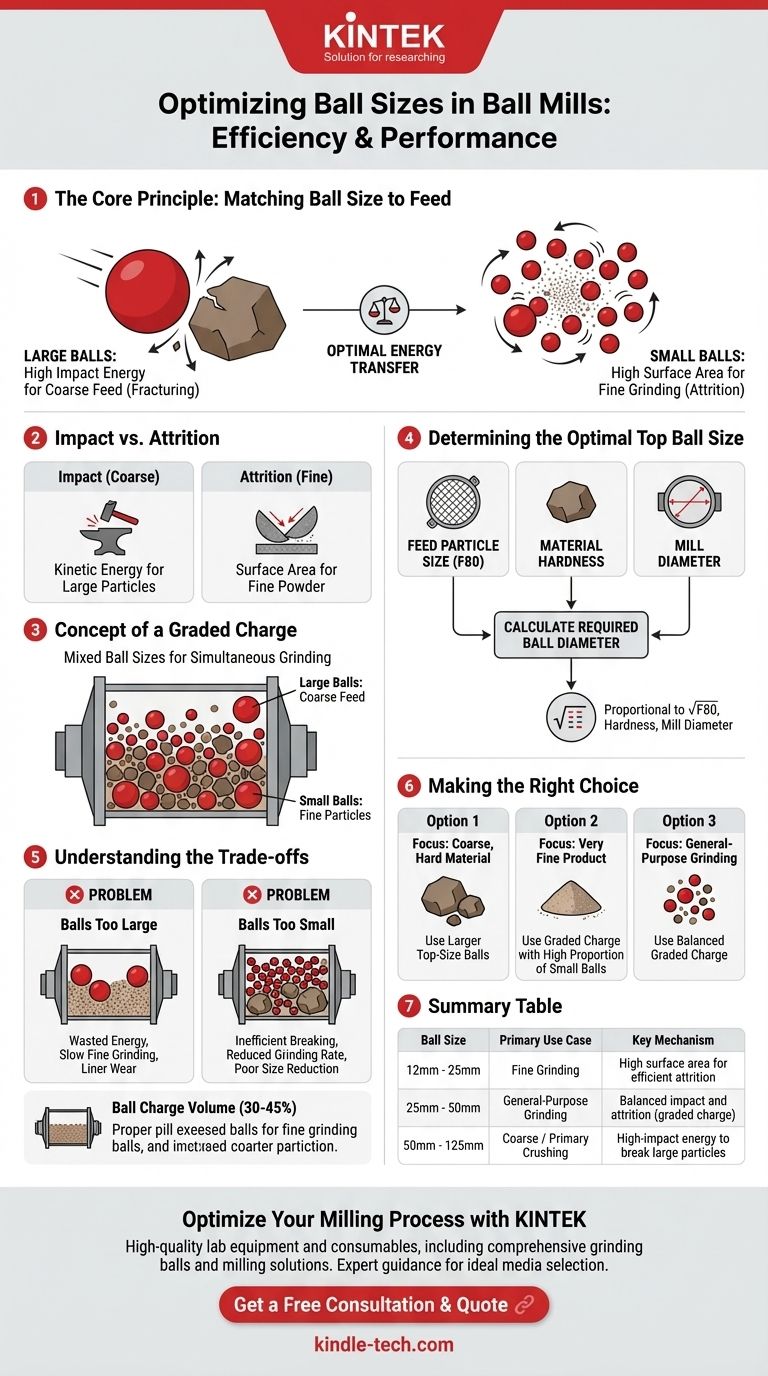

The Core Principle: Matching Ball Size to Feed Size

The entire goal of selecting a ball size is to ensure the most efficient transfer of energy to break down your target material. This involves two primary mechanisms: impact and attrition.

Why Larger Balls Are Needed for Coarse Material

Larger, heavier balls carry more kinetic energy. When they are lifted by the rotation of the mill and fall, they create a powerful impact force capable of fracturing large, coarse particles.

Without sufficient mass, the balls will simply bounce off the larger feed material, doing little to no work and wasting energy.

Why Smaller Balls Are Essential for Fine Grinding

Once the large particles are broken, the grinding process shifts. Smaller balls have a significantly greater total surface area for a given weight compared to larger balls.

This increased surface area promotes particle-on-particle and ball-on-particle rubbing, a process known as attrition. This is far more efficient for reducing small particles into a fine powder.

The Concept of a "Graded Charge"

Most industrial applications do not use a single ball size. They use a graded charge, which is a carefully selected mixture of different ball sizes.

This allows the mill to operate efficiently on a range of particle sizes simultaneously. The large balls handle the initial coarse feed, while the smaller balls work on the finer particles as they are created.

How to Determine the Optimal Top Ball Size

While a graded charge is common, its composition is determined by calculating the maximum, or "top," ball size required for your specific process.

The Critical Factor: Feed Particle Size (F80)

The most important variable is the size of the material entering the mill. This is often measured as the F80, which is the mesh size that 80% of the feed material passes through.

A larger F80 (coarser feed) requires a larger top-size ball to initiate the breaking process effectively.

A Common Industry Guideline

A well-established engineering principle, derived from the work of Fred C. Bond, provides a reliable starting point for this calculation. While the precise formula can be complex, the relationship is clear.

The required ball diameter is proportional to the square root of the feed particle size (F80), also factoring in material hardness and mill diameter. A larger feed requires a larger ball.

The Role of Mill Diameter

The diameter of the mill dictates the drop height of the balls. A larger mill diameter provides a greater drop, generating more impact energy for any given ball size.

Therefore, a very large diameter mill may be able to use slightly smaller balls than a small diameter mill to achieve the same breaking force on the same feed material.

Understanding the Trade-offs

Selecting the wrong ball size leads directly to inefficiency, increased operating costs, and poor results.

The Problem with Balls That Are Too Large

If your grinding balls are too large for the feed material, the energy is wasted. The massive impacts are not needed, and the limited number of contact points (due to fewer balls) makes fine grinding via attrition extremely slow. This can also cause excessive wear on the mill liners.

The Problem with Balls That Are Too Small

If the balls are too small, they will lack the kinetic energy to fracture the coarsest feed particles. The mill will operate inefficiently, grinding rates will plummet, and you will be unable to achieve the desired size reduction.

The Impact of Ball Charge Volume

The ball size must also be considered in relation to the charge volume—the percentage of the mill filled with balls. This is typically between 30% and 45%.

An incorrect charge volume can disrupt the cascading motion of the media, reducing grinding efficiency regardless of whether the ball size is correct.

Making the Right Choice for Your Process

The final decision comes down to your primary operational goal. By understanding the principles, you can select a grinding media charge that is optimized for your specific application.

- If your primary focus is breaking down coarse, hard material: Your charge should be weighted towards a larger top-size ball calculated based on your F80 feed size.

- If your primary focus is achieving a very fine final product: Use a graded charge with a smaller average ball size and a higher proportion of small balls to maximize grinding surface area.

- If your primary focus is general-purpose grinding across a wide feed size: Employ a balanced, graded charge of multiple ball sizes to handle coarse impact and fine attrition simultaneously.

Ultimately, proper ball size selection is one of the most critical levers you can pull to control the efficiency and effectiveness of your grinding circuit.

Summary Table:

| Ball Size | Primary Use Case | Key Mechanism |

|---|---|---|

| 12mm - 25mm | Fine Grinding | High surface area for efficient attrition |

| 25mm - 50mm | General-Purpose Grinding | Balanced impact and attrition (graded charge) |

| 50mm - 125mm | Coarse / Primary Crushing Output | High-impact energy to break large particles |

Optimize Your Milling Process with KINTEK

Choosing the correct grinding media is critical for your lab's productivity and budget. The wrong ball size leads to wasted energy, increased wear, and inconsistent results.

KINTEK specializes in providing high-quality lab equipment and consumables, including a comprehensive range of grinding balls and milling solutions. Our experts can help you select the ideal media size and composition for your specific material and application, ensuring you achieve maximum grinding efficiency and the finest possible particle size.

Contact us today to discuss your milling needs and let our specialists help you enhance your lab's performance.

Get a Free Consultation & Quote

Visual Guide

Related Products

- Stainless Steel Laboratory Ball Mill for Dry Powder and Liquid with Ceramic Polyurethane Lining

- Laboratory Ball Mill Jar Mill with Metal Alloy Grinding Jar and Balls

- Laboratory Horizontal Planetary Ball Mill Milling Machine

- Laboratory Planetary Ball Mill Rotating Ball Milling Machine

- High-Energy Omnidirectional Planetary Ball Mill Milling Machine for Laboratory

People Also Ask

- What are the disadvantages of a ball mill? High Energy Use, Noise, and Contamination Risks

- What is the purpose of ball milling? A Versatile Tool for Material Synthesis and Modification

- What is the function of ball milling equipment in NZSSP electrolyte preparation? Optimize NASICON Solid-State Synthesis

- What role does a planetary ball mill play in eggshell fertilizer production? Unlock Superior Chemical Reactivity

- Why use ball milling for NMC cathode materials? Achieve Precision Particle Sizing for Composite Cathodes