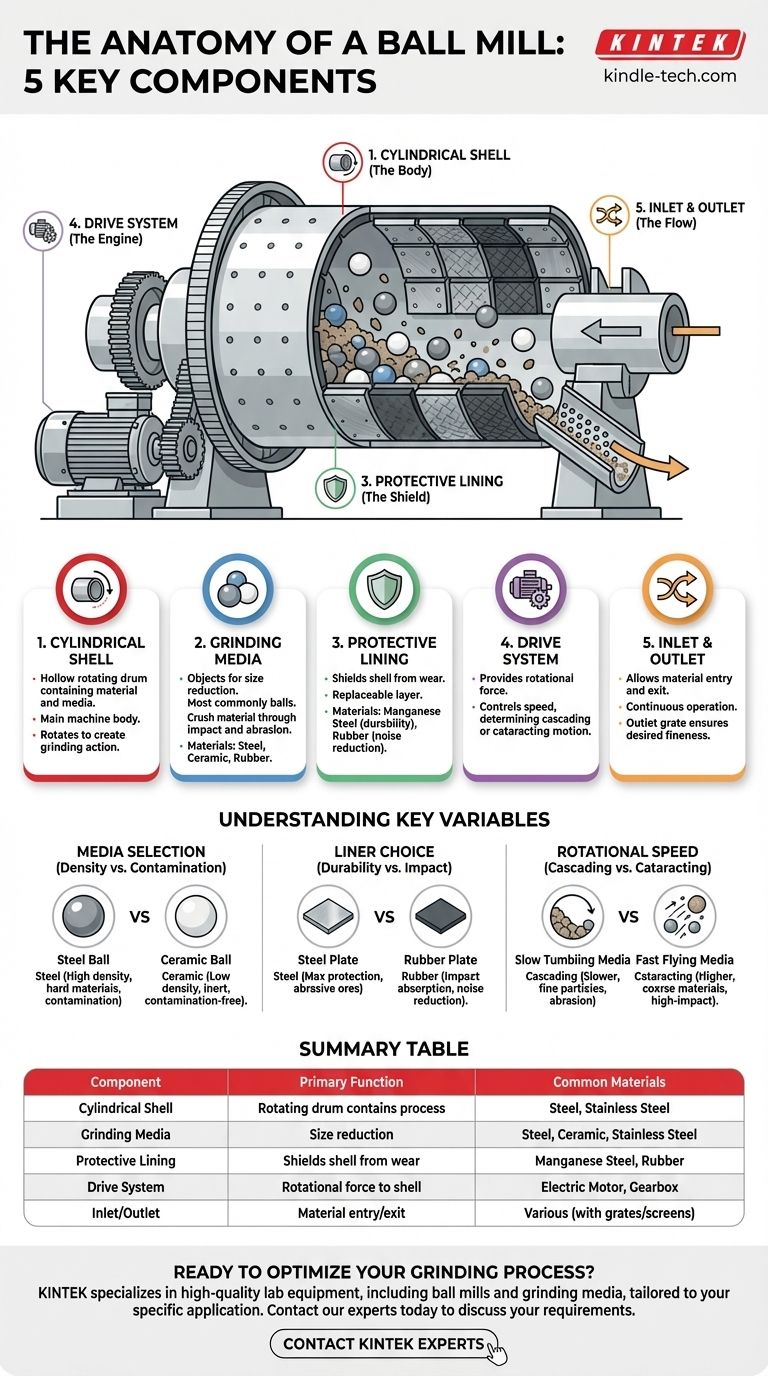

At its core, a ball mill is a system built from five primary components. These are the cylindrical shell, the grinding media, the protective lining, the drive system that rotates the shell, and the inlet/outlet ports for material handling. Together, they create a controlled environment for powerful size reduction through impact and abrasion.

A ball mill is not just a simple rotating drum; it is an engineered system. The interaction between the shell's rotation, the type of grinding media, and the protective liner is what determines the efficiency and quality of the final ground product.

The Anatomy of a Ball Mill: A Functional Breakdown

To understand how a ball mill achieves its purpose, you must understand the function of each individual component and how it contributes to the overall process.

The Cylindrical Shell (The Body)

The cylindrical shell is the hollow, rotating drum that contains the material and grinding media. It is the main body of the machine.

This shell is mounted on an axis that is either perfectly horizontal or at a slight angle. The rotation of the shell is what lifts the grinding media and creates the grinding action.

The Grinding Media (The Force)

The grinding media are the objects responsible for the actual size reduction. These are most commonly balls, which give the mill its name.

This media is partially filled into the shell along with the material to be ground. As the shell rotates, the media is lifted and then tumbles or cascades down, crushing and grinding the material through impact and abrasion.

Common media materials include high-density steel, stainless steel, ceramic, or even rubber, chosen based on the grinding requirements and the need to avoid contamination.

The Protective Lining (The Shield)

The inner surface of the shell is protected by a replaceable lining. This layer serves the critical function of protecting the shell from the intense wear and abrasion caused by the grinding process.

These liners are made from highly abrasion-resistant materials. Manganese steel is common for its extreme durability, while rubber linings can be used to reduce noise and are suitable for certain types of impact.

The Drive System (The Engine)

The drive system provides the rotational force to the cylindrical shell. This is typically an electric motor connected to the shell via a gearbox and gearing system.

The speed of rotation is a critical operating parameter. It dictates whether the grinding media tumbles gently (cascading) or is thrown for high-impact collisions (cataracting).

The Inlet and Outlet (The Flow)

For the mill to operate continuously, it must have a way for material to enter and exit. The inlet, often through a hollow journal or opening, allows for the feed of raw material.

The outlet allows the ground material to be discharged from the mill. In many designs, a grate or screen at the outlet ensures that only material ground to the desired fineness can exit.

Understanding the Key Variables

The effectiveness of a ball mill is not fixed; it depends on the choices made for its core components. Understanding these variables is key to optimizing the process.

Media Selection: Density vs. Contamination

The choice of grinding media is a primary consideration. Steel balls are very dense and highly effective for hard materials, but they can introduce metallic contamination into the product.

Ceramic balls are less dense but are inert, making them ideal for applications like pharmaceuticals or high-purity ceramics where product contamination is unacceptable.

Liner Choice: Durability vs. Impact Profile

A steel liner offers maximum protection against abrasion and is the standard for grinding hard, abrasive ores.

A rubber liner is less durable but offers better impact absorption, reduces noise, and can have a longer life in applications where breakage from high-impact cataracting is a concern.

Rotational Speed: Cascading vs. Cataracting

Slower rotational speeds cause the media to tumble down the face of the load in a cascading motion. This results in grinding primarily through abrasion and is effective for creating very fine particles.

Higher speeds throw the media into the air in a cataracting motion. This creates high-energy impacts, ideal for quickly breaking down coarser, harder materials.

Matching Components to Your Goal

Your specific objective dictates the optimal configuration of the mill.

- If your primary focus is maximum grinding efficiency for hard materials: Use high-density steel media with a durable manganese steel liner and operate at a higher speed to induce cataracting.

- If your primary focus is preventing product contamination: Use ceramic or other non-metallic grinding media and potentially a non-metallic liner to ensure product purity.

- If your primary focus is reducing operational noise and liner wear: Consider using rubber liners, which absorb impact energy more effectively than steel.

By viewing the ball mill as an adaptable system, you can tailor its components to perfectly match your specific material and desired outcome.

Summary Table:

| Component | Primary Function | Common Materials |

|---|---|---|

| Cylindrical Shell | Rotating drum that contains the grinding process | Steel, Stainless Steel |

| Grinding Media | Objects that perform the actual size reduction | Steel, Ceramic, Stainless Steel |

| Protective Lining | Shields the shell from wear and abrasion | Manganese Steel, Rubber |

| Drive System | Provides rotational force to the shell | Electric Motor, Gearbox |

| Inlet/Outlet | Allows material to enter and exit the mill | Various (often with grates/screens) |

Ready to optimize your grinding process? The right ball mill configuration is critical for achieving your desired particle size, purity, and efficiency. At KINTEK, we specialize in providing high-quality lab equipment, including ball mills and grinding media, tailored to your specific application—whether you need maximum grinding power, contamination-free processing, or noise reduction.

Contact our experts today to discuss your requirements and let us help you select the perfect solution for your laboratory needs.

Visual Guide

Related Products

- Stainless Steel Laboratory Ball Mill for Dry Powder and Liquid with Ceramic Polyurethane Lining

- Laboratory Ball Mill Jar Mill with Metal Alloy Grinding Jar and Balls

- Laboratory Single Horizontal Jar Mill

- Laboratory Four-Body Horizontal Jar Mill

- Laboratory Planetary Ball Mill Rotating Ball Milling Machine

People Also Ask

- What is the function of high-energy sand milling in Si2N2O-based ceramic composites? Optimize Powder Refinement Today

- What is the difference between a grinding mill and a hammer mill? Choose the Right Mill for Your Material

- What function does a laboratory vibratory mill serve? Achieve 1–5 µm Precision for Cs-Aluminosilicate Powder

- What role does mechanochemical grinding play in the raw material preparation of lithium-based ceramics? Boost Efficiency

- What are the limitations of ball milling method? Understand the trade-offs of mechanical grinding

- What is the objective of utilizing a high-speed uniaxial ball mill at 625 rpm? Master Dense LLZ Composite Mixing

- What is the function of an agate mortar and pestle? Ensure Purity in Halide Solid-State Electrolyte Synthesis

- What is a roller mill used for in the pharmaceutical industry? A Key Tool for Dry Granulation