In practice, ball mills use a wide range of grinding ball sizes, typically from as small as a few millimeters up to over 100 millimeters (about 4 inches) in diameter. The selection is not arbitrary; it is a critical engineering decision based on the specific grinding application. Using the wrong size results in significant inefficiency, increased energy consumption, and a failure to achieve the desired final product.

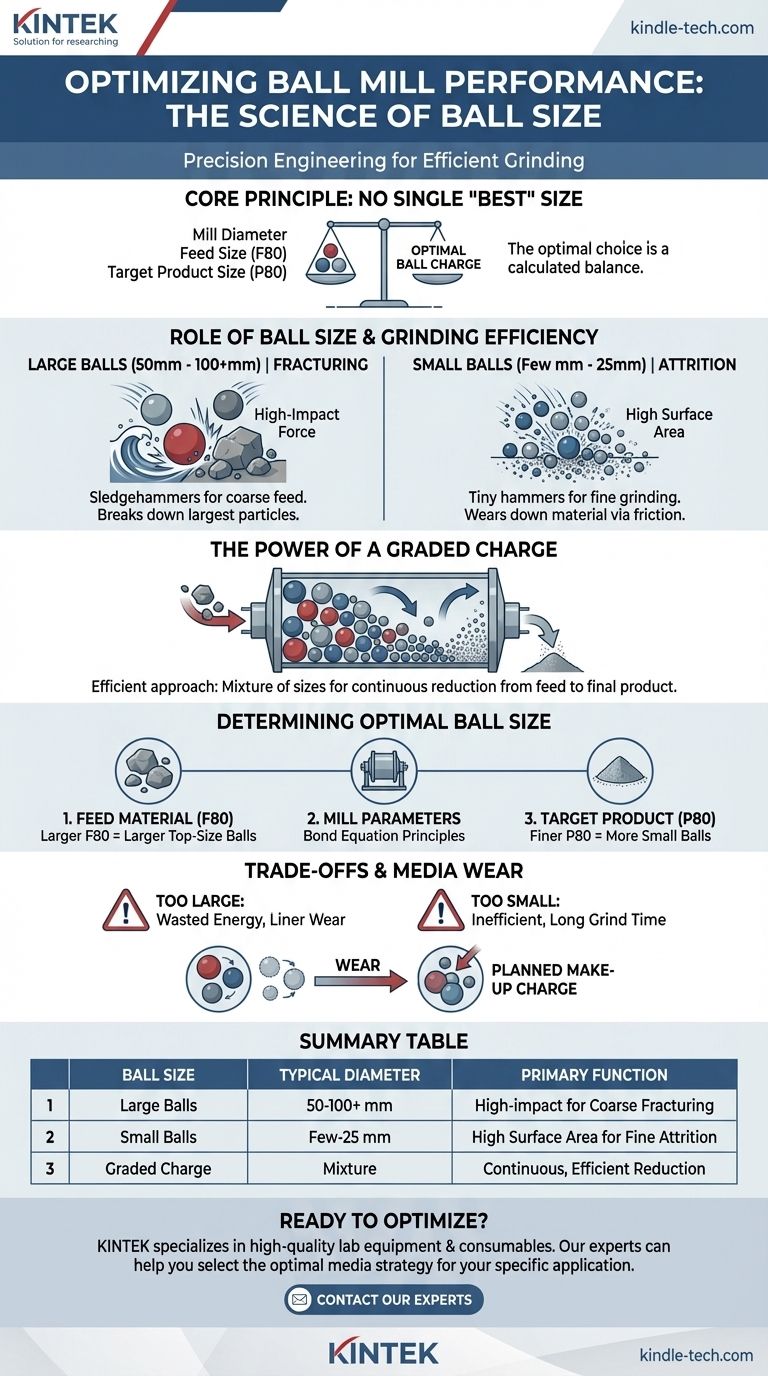

The core principle is that there is no single "best" ball size. The optimal choice is a calculated balance determined by the mill's diameter, the size of the material being fed into it, and the target particle size of the final product. Often, a carefully selected mixture of sizes yields the best results.

The Role of Ball Size in Grinding Efficiency

The size of the grinding media directly dictates the type and magnitude of forces applied inside the mill. Understanding this relationship is the first step toward optimizing your process.

Large Balls for Coarse Grinding

Large-diameter balls are heavy and deliver high-energy, high-impact forces when they cascade within the mill. Think of them as sledgehammers.

Their primary function is to break down the largest particles in the feed material. This high impact is essential for the initial stage of size reduction, known as fracturing.

Small Balls for Fine Grinding

Smaller balls have significantly more surface area per unit of weight and create a vastly greater number of contact points within the charge. Think of them as a collection of tiny hammers or a coarse abrasive.

They excel at attrition grinding, where material is worn down by friction and lower-energy impacts. This is the mechanism needed to reduce already small particles into a fine powder.

The Power of a Graded Charge

For most applications, the most efficient approach is a graded charge, which is a mixture of different ball sizes.

In this setup, the large balls break the coarse feed, and the smaller balls then grind the resulting smaller particles into the final desired size. This creates a continuous and efficient reduction process throughout the mill.

How to Determine the Optimal Ball Size

Selecting the right ball size is a science, not a guess. Engineers rely on established principles and calculations to determine the ideal media charge for a specific task.

The Bond Equation and Top Ball Size

The foundational work by Fred Bond provides a formula to calculate the "top size" (the largest diameter ball) needed for a given process. While the exact formula is complex, the principle is straightforward.

The required ball diameter is primarily a function of the feed material's size, the mill's diameter, and the material's properties. A simplified concept is that the optimal top ball size is proportional to the square root of the feed particle size.

Matching Ball Size to Feed Material (F80)

The most critical input for this calculation is the starting size of the material. This is often documented as the F80, which is the mesh size that 80% of the feed material passes through.

A larger F80 requires larger top-size balls with enough impact energy to initiate fracture.

Considering the Target Particle Size (P80)

The desired output, or P80 (the size that 80% of the product passes through), also dictates the media charge.

To achieve a very fine P80, the charge must contain a sufficient quantity of smaller balls to provide the necessary surface area for attrition grinding.

Understanding the Trade-offs and Common Pitfalls

Choosing incorrectly can lock in inefficiency and high operational costs. Avoiding these common mistakes is critical.

The Problem with Balls That Are Too Large

If the balls are too large for the feed material, energy is wasted. The impacts are unnecessarily powerful, causing excessive wear on the mill liners and the media itself without a proportional increase in grinding performance. It can be less effective at breaking smaller particles.

The Inefficiency of Balls That Are Too Small

If the balls are too small, they may not possess enough kinetic energy to effectively break the larger particles in the feed. This results in extremely long grinding times, high energy consumption, and a potential failure to reach the target particle size altogether.

Accounting for Media Wear

Grinding balls are consumable; they continuously wear down and become smaller. This means the size distribution within the mill is constantly changing.

An efficient operation requires a planned make-up charge of new, top-size balls to be added periodically. This practice replaces the weight lost to wear and maintains the optimal size distribution for consistent performance.

Selecting Your Grinding Media Strategy

Your choice of grinding media should be a direct reflection of your operational goal. Use these principles to guide your decision-making process.

- If your primary focus is breaking down large, coarse feed: Your charge should be dominated by the calculated "top size" balls necessary to provide high-impact energy for initial fracturing.

- If your primary focus is producing a very fine powder: You will need a graded charge with a significant proportion of smaller balls to maximize the surface area available for attrition grinding.

- If your primary focus is optimizing an existing process: Conduct a "grind-out" test to analyze the current media size distribution and wear rate, then adjust your make-up charge to better align with the calculated ideal.

A methodical approach to ball size selection transforms milling from an unpredictable art into a predictable and efficient science.

Summary Table:

| Ball Size Role | Typical Diameter | Primary Function |

|---|---|---|

| Large Balls | 50 mm - 100+ mm | High-impact force for breaking coarse feed material (Fracturing) |

| Small Balls | A few mm - 25 mm | High surface area for fine grinding via attrition (Friction) |

| Graded Charge (Mixture) | Combination of sizes | Continuous and efficient size reduction from feed to final product (P80) |

Ready to Optimize Your Milling Process?

Choosing the right grinding media is critical for achieving your target particle size (P80) while minimizing energy consumption and media wear. KINTEK specializes in providing high-quality lab equipment and consumables, including a full range of grinding balls for ball mills. Our experts can help you select the optimal media strategy for your specific application, whether you're focused on coarse fracturing or fine powder production.

Contact our grinding experts today to discuss your needs and enhance your lab's efficiency!

Visual Guide

Related Products

- Laboratory Jar Ball Mill with Alumina Zirconia Grinding Jar and Balls

- Laboratory Single Horizontal Jar Mill

- High Energy Planetary Ball Mill Milling Machine for Laboratory

- High Energy Planetary Ball Mill Milling Machine for Laboratory

- High-Energy Omnidirectional Planetary Ball Mill Milling Machine for Laboratory

People Also Ask

- What is the function of a planetary ball mill in the synthesis of (Cu–10Zn)-Al2O3 nanocomposites? High-Energy Alloying

- What is the speed range of a ball mill? Find Your Optimal Grinding Efficiency

- What are the unique energy transfer characteristics of PBM? Master Complex Heterocyclic Synthesis

- What is the function of a planetary ball mill in MAX phase powder preparation? Unlock High-Purity Atomic Homogeneity

- What are the requirements for ball milling jars in LiMOCl4 synthesis? Ensure Safety and Purity in High-Pressure Reactions