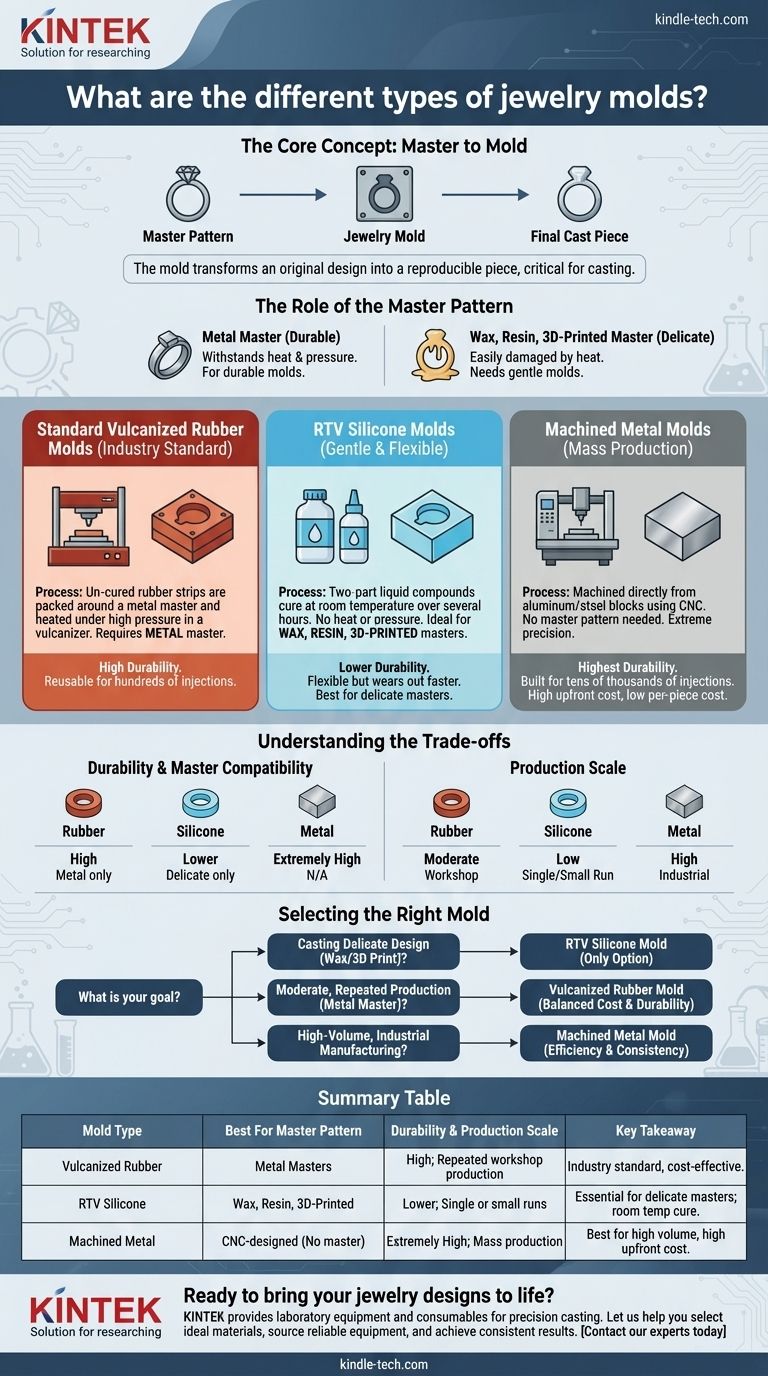

When creating jewelry through casting, the mold is the critical tool that turns an original design into a reproducible piece. The three primary types of molds used in the industry are standard vulcanized rubber, room temperature vulcanizing (RTV) silicone, and machined metal molds, each suited for different master patterns and production scales.

The most critical factor in choosing a jewelry mold is the material of your original model, or "master pattern." The heat and pressure tolerance of your master dictates whether you can use a durable rubber mold or if you require a gentler silicone mold.

The Role of the Master Pattern

Before choosing a mold, you must first understand your master pattern. This is the original, high-detail model of the jewelry piece from which the mold will be made.

Metal vs. Wax Masters

A metal master is a highly durable model of the final piece, typically made from a non-precious metal. Its primary advantage is its ability to withstand the high heat and pressure required for certain molding processes.

A wax, resin, or 3D-printed master is much more delicate. These materials are easier to shape and detail but will melt, warp, or break under the conditions used to create traditional rubber molds.

A Breakdown of Jewelry Mold Types

The key difference between mold types lies in the temperature and pressure required to cure them, which in turn determines the type of master pattern they can accommodate.

Standard Vulcanized Rubber Molds

This is the long-standing industry workhorse. These molds are created by packing strips of un-cured rubber around a master pattern and then heating it under high pressure in a machine called a vulcanizer.

This process, known as vulcanization, cross-links the rubber molecules, creating a tough, durable, and reusable mold. Because of the intense heat and pressure, these molds can only be made from a metal master.

RTV (Room Temperature Vulcanizing) Silicone Molds

RTV silicone molds are the modern solution for delicate master patterns. These are typically two-part liquid compounds that, when mixed, cure at room temperature over several hours without any external pressure.

Because no heat is involved, RTV silicone is the best and often only choice for masters made of wax, plastic, resin, or other low-temperature materials. The resulting molds are flexible but less durable than vulcanized rubber.

Milled Metal Molds

For true mass production, jewelers turn to metal molds. These are not made from a master pattern in the traditional sense but are instead machined directly out of a block of aluminum or steel using CNC (Computer Numerical Control) equipment.

These molds are extremely precise and can withstand tens of thousands of wax injections without any degradation in quality. They represent a significant upfront investment but offer the lowest cost-per-piece at a very high volume.

Understanding the Trade-offs

Choosing a mold involves balancing durability, master pattern compatibility, and cost.

Durability vs. Master Material

A vulcanized rubber mold can last for hundreds or even thousands of injections, making it highly cost-effective for ongoing production. However, this durability comes at the cost of requiring a robust metal master.

Silicone molds are gentler on delicate masters but are also softer and will wear out more quickly, requiring more frequent replacement.

Production Scale and Cost

For a single piece or a very small run from a wax carving, an RTV silicone mold is the most accessible and cost-effective option.

For standard, repeated workshop production from a metal master, vulcanized rubber offers the best balance of cost and longevity.

For industrial-scale manufacturing, the high initial cost of a milled metal mold is justified by its unparalleled durability and precision over a massive production run.

Selecting the Right Mold for Your Project

Your choice should be guided directly by your starting point and your final goal.

- If your primary focus is casting a hand-carved wax or 3D-printed design: RTV silicone is your only viable option, as it will capture the detail without destroying the delicate master.

- If your primary focus is moderate, repeatable production from a durable metal master: Standard vulcanized rubber is the industry-standard choice for its excellent balance of durability and cost.

- If your primary focus is high-volume, industrial-scale manufacturing: Investing in a precision-milled metal mold provides the highest level of efficiency and consistency.

Matching your mold material to your master pattern and production goals is the first step to successful jewelry casting.

Summary Table:

| Mold Type | Best For Master Pattern | Durability & Production Scale | Key Takeaway |

|---|---|---|---|

| Vulcanized Rubber | Metal Masters | High durability; ideal for repeated workshop production. | Industry standard for durable, cost-effective molds. |

| RTV Silicone | Wax, Resin, or 3D-Printed Masters | Lower durability; perfect for single pieces or small runs. | The only option for delicate masters; cures at room temperature. |

| Machined Metal | CNC-designed for mass production | Extremely high durability; built for tens of thousands of injections. | Best for high-volume manufacturing; high upfront cost. |

Ready to bring your jewelry designs to life with the perfect mold?

The right mold is the foundation of successful casting. At KINTEK, we specialize in providing the laboratory equipment and consumables that jewelers and casting professionals rely on for precision and quality.

We can help you:

- Select the ideal materials for your specific master pattern and production goals.

- Source reliable equipment for your casting and molding workflow.

- Achieve consistent, high-quality results batch after batch.

Let's discuss your project. Contact our experts today to find the perfect solution for your laboratory and jewelry-making needs.

Visual Guide

Related Products

- Polygon Press Mold for Lab

- Special Shape Press Mold for Lab

- Cylindrical Press Mold with Scale for Lab

- Special Heat Press Mold for Lab Use

- Ball Press Mold for Lab

People Also Ask

- What functions do graphite molds perform? Critical Roles in Vacuum Hot-Pressing C_fiber/Si3N4 Composites

- How do specialized molds and presses work in solid-state battery assembly? Achieve Superior Densification

- What are the critical performance requirements for hot pressing molds? Ensure Precision in Magnesium Alloy Processing

- What function do high-strength graphite molds serve in CoSb3 sintering? Enhancing Density and Purity for Thermoelectrics

- What functions do High-Purity Graphite Molds perform? Enhance Your Aluminum Matrix Composite Hot-Press Sintering

- Why are high-strength graphite molds required during the vacuum hot pressing process for TiAl/Ti6Al4V composites?

- What role do metal molds play during the cold pressing stage of VC/Cu composite fabrication? High-Precision Shaping

- How do high-precision molds contribute to Li6PS5Cl electrolyte membrane formation? Achieve Perfect Density and Thickness