The primary disadvantages of a colloidal mill are its significant heat generation, its limited ability to reduce the size of hard particles, and its high susceptibility to wear from abrasive materials. While excellent for creating emulsions and dispersions of soft materials, it is fundamentally a high-shear device, not a true grinding mill, which creates specific operational challenges.

A colloidal mill excels at liquid-liquid emulsification and de-agglomerating soft solids. Its core disadvantage is that the very mechanism that makes it effective—intense mechanical shear—also generates heat and wears down components, making it unsuitable for heat-sensitive, abrasive, or hard crystalline materials.

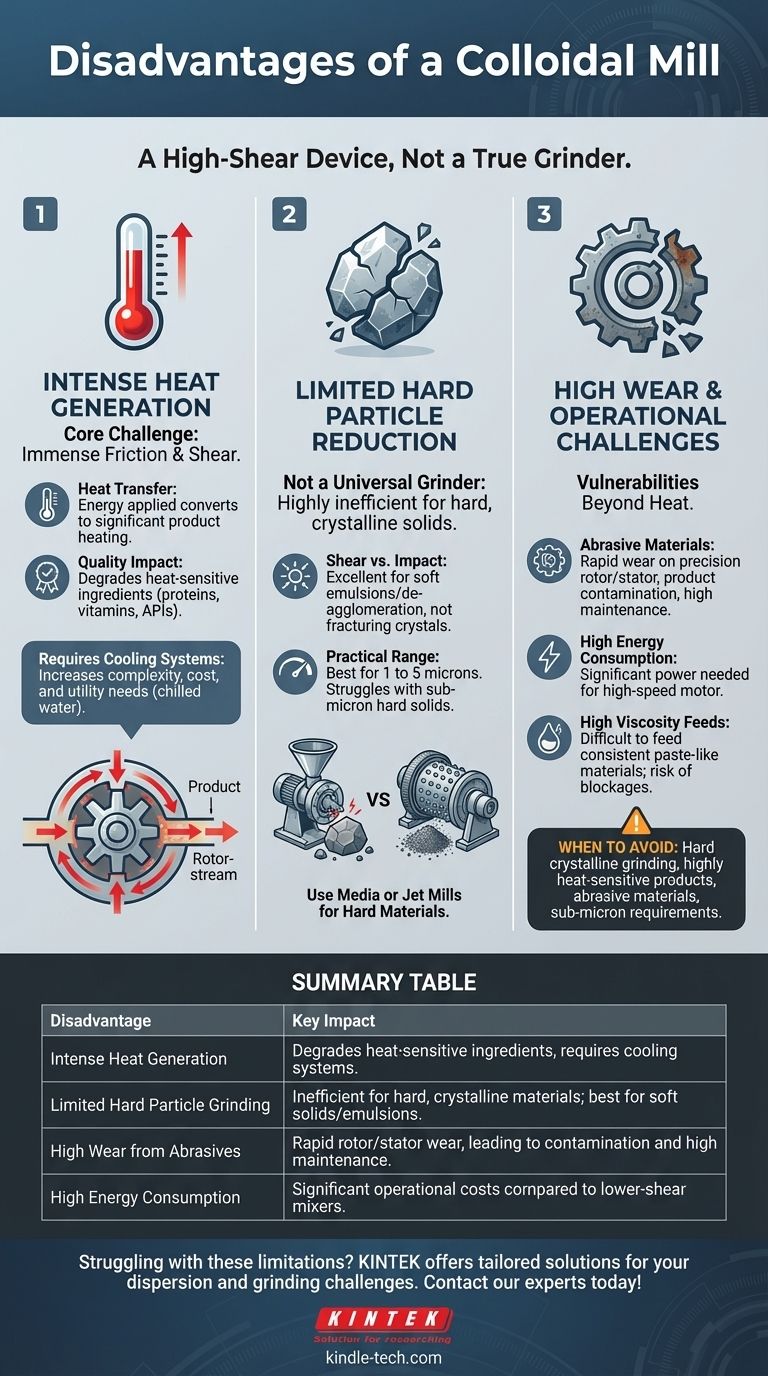

The Core Operational Challenge: Intense Heat Generation

A colloidal mill operates by forcing a fluid through a very narrow gap between a high-speed rotor and a stationary stator. This process creates immense friction and shear, which unavoidably generates a large amount of heat.

Why Heat is a Problem

The energy applied by the mill is converted into two things: particle size reduction and heat. A significant portion of this energy becomes heat, which is transferred directly into your product.

This temperature increase can be substantial and rapid, especially with viscous materials or during extended processing times.

Impact on Product Quality

For many applications, this heat is more than an inconvenience; it's a critical failure point. It can degrade heat-sensitive ingredients like proteins, vitamins, and active pharmaceutical ingredients (APIs).

In food production, excess heat can alter flavors, denature textures, and spoil the final product. In chemical applications, it can trigger unwanted side reactions or change the product's stability.

The Need for Cooling Systems

To manage this, many colloidal mills must be equipped with a cooling jacket. This adds complexity, cost, and utility requirements (e.g., a chilled water supply) to the overall system, increasing both capital and operational expenditure.

Limitations in Particle Size Reduction

It is crucial to understand that a colloidal mill is not a universal "grinder." Its effectiveness is highly dependent on the nature of the material being processed.

Shear vs. Impact Grinding

A colloidal mill works primarily through hydraulic shear and some mechanical shearing from the rotor-stator teeth. This force is excellent for tearing apart soft agglomerates and breaking down liquid droplets to create stable emulsions.

However, it is highly inefficient for breaking down hard, crystalline primary particles. True grinding of these materials requires high-energy impact, like that found in a ball mill, media mill, or jet mill.

The "Grinding" Misconception

A colloidal mill will struggle to reduce hard solids (like minerals or pigments) to a very fine particle size. While it may de-agglomerate them, it will not efficiently fracture the primary crystals.

Attempting to achieve fine grinding of hard materials will result in extremely long processing times, excessive heat generation, and accelerated wear on the machine.

Practical Particle Size Floor

For most applications, a colloidal mill is best suited for achieving particle sizes in the range of 1 to 5 microns. Achieving consistent sub-micron results, especially with solids, is often better accomplished with other technologies like high-pressure homogenizers or media mills.

Understanding the Trade-offs and Vulnerabilities

Beyond heat and particle size limitations, several other factors can make a colloidal mill the wrong choice for a given process.

High Sensitivity to Abrasive Materials

This is one of the most significant disadvantages. If the feed material contains hard, abrasive particles (e.g., silica, alumina, pigments), they will cause rapid and severe wear on the precisely machined rotor and stator.

This wear increases the gap between the components, drastically reducing the mill's efficiency. It also introduces metallic contamination into the product and leads to costly downtime and frequent parts replacement.

High Energy Consumption

The high-speed motor required to generate the necessary shear force consumes a significant amount of electrical energy. Compared to lower-shear mixing equipment, the operational cost of a colloidal mill can be substantial, particularly for large-scale production.

Not Ideal for High Viscosity Feeds

While a colloidal mill can handle a range of viscosities, extremely thick, paste-like materials can be problematic. They may be difficult to feed consistently into the narrow rotor-stator gap, leading to poor processing, blockages, and increased heat generation.

When to Avoid a Colloidal Mill

Choosing the right equipment requires a clear understanding of its limitations. Based on these disadvantages, you can make a more informed decision.

- If your primary focus is grinding hard, crystalline materials: A colloidal mill is unsuitable; consider an impact-based technology like a media mill or jet mill.

- If you are processing highly heat-sensitive products: A colloidal mill is only viable with an effective cooling system, or you should consider a lower-energy alternative.

- If your material is abrasive: The high maintenance costs and product contamination risk make a colloidal mill a poor choice.

- If you need to achieve consistent sub-micron particle sizes: A high-pressure homogenizer (for emulsions) or a media mill (for solid dispersions) will provide far better and more reliable results.

Understanding these limitations is the key to selecting the right dispersion technology that ensures both product quality and operational efficiency.

Summary Table:

| Disadvantage | Key Impact |

|---|---|

| Intense Heat Generation | Can degrade heat-sensitive ingredients, requires cooling systems. |

| Limited Hard Particle Grinding | Inefficient for hard, crystalline materials; best for soft solids/emulsions. |

| High Wear from Abrasives | Rapid rotor/stator wear, leading to contamination and high maintenance. |

| High Energy Consumption | Significant operational costs compared to lower-shear mixers. |

Struggling with heat, wear, or particle size limitations in your lab? The right equipment is critical for your product's quality and your operational efficiency. KINTEK specializes in lab equipment and consumables, offering solutions tailored to your specific dispersion and grinding challenges. Contact our experts today to find the perfect technology for your application and ensure optimal results.

Visual Guide

Related Products

- Laboratory Single Horizontal Jar Mill

- Laboratory Test Sieves and Sieving Machines

- Laboratory Horizontal Planetary Ball Mill Milling Machine

- High Energy Planetary Ball Mill for Laboratory Horizontal Tank Type Milling Machine

- High Energy Planetary Ball Mill Milling Machine for Laboratory

People Also Ask

- Why use zirconia ball milling jars for SiC/ZTA composite powders? Ensure High Purity & Efficient Particle Refinement

- Why are excellent sealing and corrosion resistance required for WC-10Co ball milling? Ensure High-Purity Mixing Results

- Why is a ball mill jar lined with Y-ZrO2 required for Na3PS4 synthesis? Ensuring Purity in Sulfide Electrolytes

- Why are tungsten carbide grinding jars and balls preferred for high-purity lithium ceramic powders? Ensure Peak Purity.

- How do stainless steel grinding jars and balls contribute to mechanical alloying? Optimize HEA Powder Synthesis