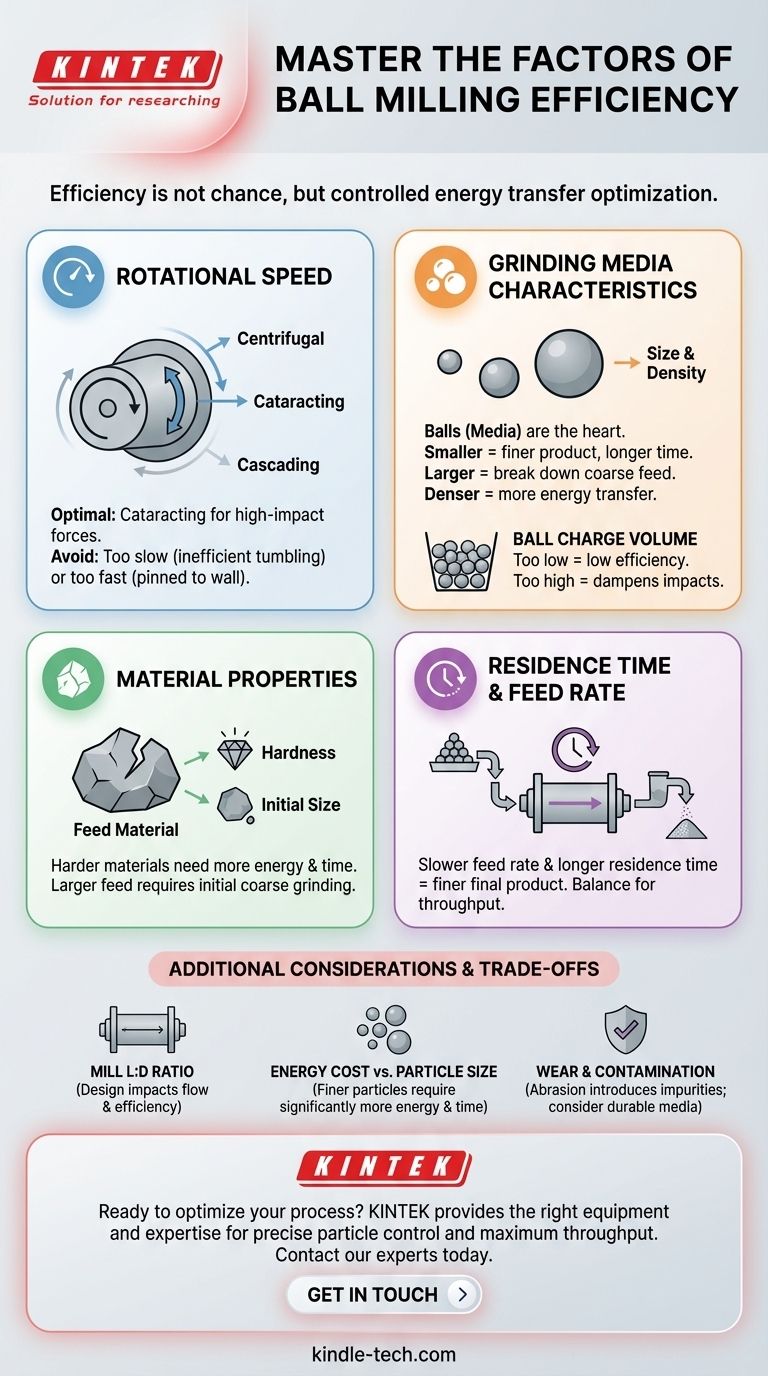

The efficiency of a ball milling process is not a matter of chance, but the result of a controlled interplay between several critical factors. The most significant variables include the rotational speed of the mill, the characteristics of the grinding media (the balls), the properties of the material being milled, and the duration of the milling process (residence time). Each of these elements must be carefully balanced to achieve the desired particle size and throughput.

Ball milling is fundamentally a process of energy transfer. Your success depends not on maximizing any single variable, but on optimizing the entire system to transfer mechanical energy into your material as efficiently as possible for the desired outcome.

Core Mechanical Factors: Speed and Energy

The physical operation of the mill and its components are the primary levers for controlling the process. How you manage speed and the grinding media directly dictates the type and magnitude of the forces applied to your material.

Rotational Speed of the Mill

The speed at which the mill cylinder rotates is critical. Too slow, and the balls will simply tumble or "cascade," resulting in inefficient grinding. Too fast, and centrifugal force will pin the balls and material to the mill wall, preventing any effective grinding action.

The optimal speed creates a "cataracting" motion, where the balls are carried up the cylinder wall and then fall, creating the high-energy impacts necessary for particle size reduction.

Grinding Media Characteristics

The balls themselves are the heart of the process. Their size, density, and quantity must be matched to the material and the desired final particle size.

Smaller balls produce a finer final product but require longer grinding times. Larger balls are more effective at breaking down coarse feed material.

Denser and harder media transfer more energy per impact, leading to more efficient grinding, provided they are significantly harder than the material being milled.

The Ball Charge Volume

This refers to the total volume occupied by the grinding balls, typically expressed as a percentage of the mill's internal volume. Too low a charge results in infrequent impacts and low efficiency. Too high a charge restricts ball movement, dampens impacts, and wastes energy.

Material and Process Parameters

Beyond the mill's mechanics, the properties of the material and how it's introduced into the system play an equally important role in the final outcome.

Properties of the Feed Material

The inherent characteristics of the material you are grinding, such as its hardness and initial particle size, determine the energy required for reduction. Harder materials naturally demand more energy, longer residence times, or denser grinding media.

Feed Rate and Residence Time

The rate at which you introduce new material (feed rate) and the average time it spends inside the mill (residence time) are directly proportional to the degree of milling. A slower feed rate and longer residence time will result in a finer final product.

Mill Dimensions (L:D Ratio)

For industrial applications, the physical design of the mill—specifically the ratio of its length to its diameter (L:D)—impacts efficiency. An optimized L:D ratio, often around 1.6, ensures proper material flow and residence time distribution, maximizing productivity.

Understanding the Trade-offs

Optimizing ball milling is an exercise in balancing competing factors. Improving one parameter often comes at the cost of another.

The Cost of Finer Particles

Achieving a smaller final particle size is not a "free" objective. It almost always requires significantly longer grinding times, which increases both energy consumption and the potential for equipment wear.

Wear and Contamination

The constant impact and abrasion cause wear on both the grinding media and the internal lining of the mill. This wear can introduce unwanted material, or contamination, into your final product, a critical consideration for high-purity applications.

Over-Milling and Agglomeration

More is not always better. Excessive milling can be counterproductive, leading to particles so fine that they begin to re-agglomerate due to surface forces. Furthermore, the high mechanical energy can induce unintended structural or chemical changes in the material.

Optimizing the Process for Your Goal

Your ideal settings are dictated entirely by your end goal. Use the following principles to guide your decisions.

- If your primary focus is breaking down coarse material: Use larger, denser grinding media at a speed that maximizes cataracting impact force.

- If your primary focus is producing very fine or nano-sized particles: Use smaller grinding media, a higher ball charge percentage, and plan for significantly longer residence times.

- If your primary focus is maximizing throughput and efficiency: Carefully optimize the feed rate to match the mill's grinding capacity, ensuring you are not over-processing the material.

- If your primary focus is maintaining material purity: Select highly durable, non-reactive grinding media and liners to minimize contamination from wear.

Mastering these factors transforms ball milling from a brute-force process into a precise engineering tool.

Summary Table:

| Factor | Key Influence on the Milling Process |

|---|---|

| Rotational Speed | Determines the motion of the grinding balls (cascading vs. cataracting). |

| Grinding Media (Balls) | Size, density, and hardness control impact energy and final particle size. |

| Ball Charge Volume | Percentage of mill volume filled; affects impact frequency and energy. |

| Material Hardness & Size | Harder/larger feed requires more energy and longer milling times. |

| Residence Time | Duration material spends in the mill; directly impacts fineness. |

| Mill Design (L:D Ratio) | Affects material flow and residence time distribution for efficiency. |

Ready to optimize your ball milling process for superior results?

The factors outlined above are critical, but applying them to your specific lab's needs is key. KINTEK specializes in providing the right lab equipment and consumables to help you achieve precise particle size control, maximize throughput, and maintain material purity.

Our experts can help you select the ideal grinding media and configure your milling parameters for your unique application. Contact us today to discuss your requirements and let KINTEK be your partner in laboratory efficiency.

➡️ Get in Touch with Our Experts

Visual Guide

Related Products

- High-Energy Omnidirectional Planetary Ball Mill Milling Machine for Laboratory

- High-Energy Omnidirectional Planetary Ball Mill Machine for Laboratory

- High Energy Planetary Ball Mill Milling Machine for Laboratory

- Laboratory Horizontal Planetary Ball Mill Milling Machine

- Laboratory Planetary Ball Mill Rotating Ball Milling Machine

People Also Ask

- What is a planetary ball mill? Achieve Superior Fine Grinding and Mixing

- What is the difference between a ball mill and a planetary ball mill? Unlock the Right Grinding Technology for Your Lab

- How does a planetary mill work? Harnessing High-Energy Impact for Nano-Grinding

- What is a planetary ball mill? Achieve Rapid, High-Energy Grinding for Advanced Materials

- What is a planetary mill? Achieve Rapid, Fine Grinding for Lab Materials