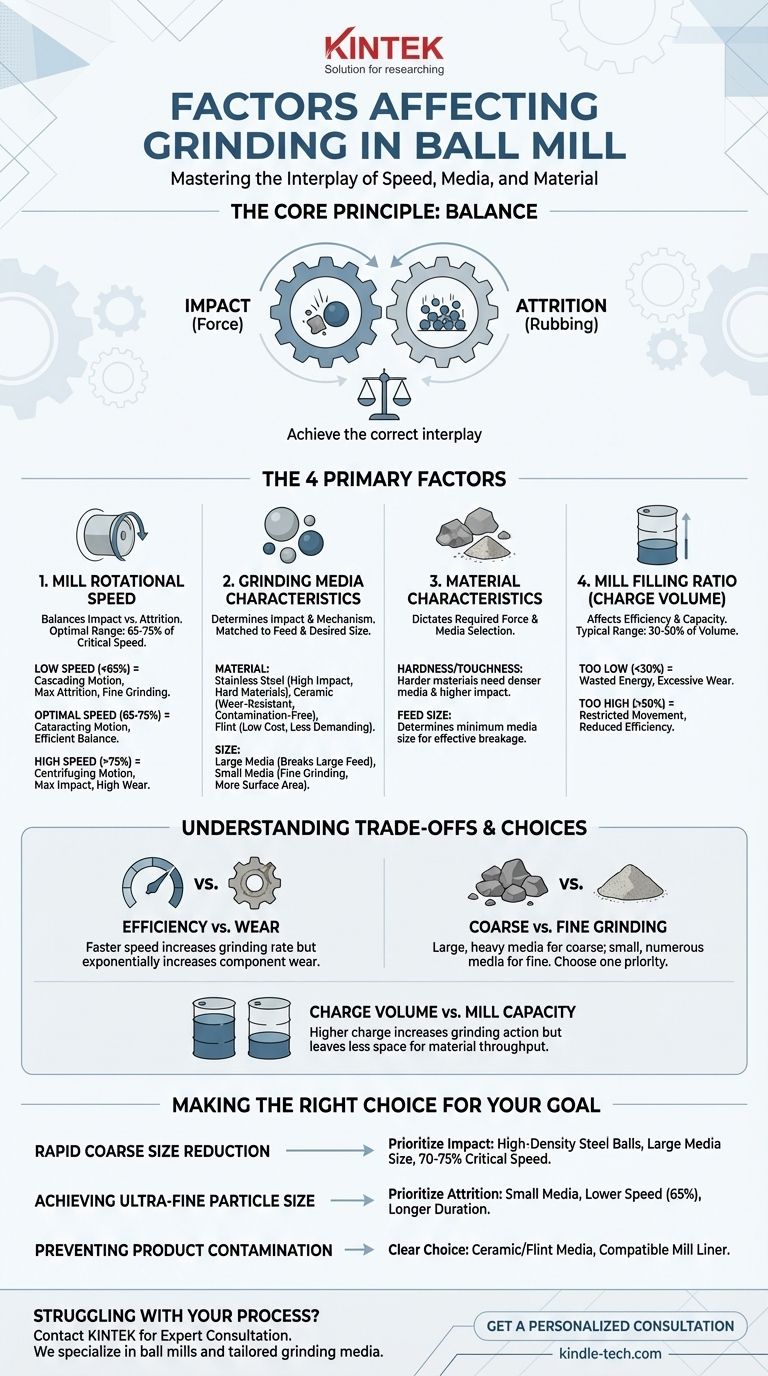

In short, the performance of a ball mill is governed by four primary factors: the rotational speed of the mill, the characteristics of the grinding media (its size and material type), the properties of the material being ground, and the volume of the mill occupied by the media, known as the filling ratio. Each of these variables is interdependent, and optimizing the grinding process requires understanding how they work in concert.

The core principle is one of balance. Effective ball milling is not about maximizing any single factor, but about achieving the correct interplay between speed, media, and material to create the specific grinding action—impact or abrasion—required for your desired outcome.

The Mechanics of Grinding Action

Before examining the variables, it's crucial to understand the two fundamental forces at work inside a ball mill. Your ability to control these forces is the key to process optimization.

Impact Grinding

This is the primary force for breaking down large, coarse particles. As the mill rotates, the grinding media (e.g., steel or ceramic balls) are lifted up the side of the drum and then cascade or cataract down, striking the material with significant force.

Attrition and Abrasion

This is the rubbing and shearing action that grinds particles down to a fine powder. It occurs as the balls tumble over one another, grinding the material trapped between them. This action is dominant at lower speeds and is essential for achieving a very fine final product.

Core Operational Factors Explained

Each operational parameter directly influences the balance between impact and attrition within the mill.

Mill Rotational Speed

Speed is arguably the most critical variable. It is not a simple case of "faster is better." Mill speed is best understood in relation to its critical speed—the theoretical speed at which the grinding media would be held against the drum by centrifugal force, resulting in no grinding at all.

- Low Speeds (below 65% of critical): At slow speeds, the media tumbles down in a cascading motion. This maximizes attrition and is ideal for fine grinding, but it is less effective at breaking large particles.

- Optimal Speeds (65-75% of critical): This range typically provides a healthy balance of impact and attrition, leading to efficient grinding for most applications.

- High Speeds (approaching critical): As speed increases, the media is thrown further, maximizing impact. However, this also dramatically increases wear on the mill liner and the media itself.

Grinding Media Characteristics

The balls or pebbles inside the mill are the tools that perform the work. Their properties are matched to the feed material and the desired final particle size.

-

Media Material: The density of the media determines the impact force.

- Stainless Steel Balls: High density provides maximum impact energy, making them ideal for breaking down hard materials quickly.

- Ceramic Balls (e.g., Alumina, Zirconia): Less dense than steel but very hard and wear-resistant. They are the standard choice when avoiding metallic contamination is critical.

- Flint Pebbles: A lower-cost, lower-density natural medium suitable for less demanding applications.

-

Media Size: There must be a proper relationship between the size of the grinding media and the size of the material being fed into the mill.

- Large Media: Used to break down large feed particles due to higher impact force per ball.

- Small Media: More effective for fine grinding. Their greater collective surface area increases the probability of particle capture and enhances attrition.

Mill Filling Ratio (Charge Volume)

This refers to the percentage of the mill's internal volume that is filled by the grinding media. The typical range is between 30% and 50%.

- Too Low (e.g., <30%): There isn't enough media to create efficient grinding action, leading to wasted energy and excessive liner wear.

- Too High (e.g., >50%): The charge becomes too packed. This restricts the free movement and tumbling of the media, reducing impact forces and overall grinding efficiency.

Material Characteristics

The properties of the material you are grinding dictate many of the other choices.

- Hardness and Toughness: Harder materials require higher impact forces to fracture. This means using denser media (steel), potentially larger balls, and operating at a speed that favors impact.

- Feed Size: The largest particles in your feed material dictate the minimum size of the grinding media required to break them effectively.

Understanding the Trade-offs

Optimizing a ball mill is a process of managing compromises. Changing one variable will inevitably affect others.

Efficiency vs. Wear

Increasing mill speed will generally increase the rate of grinding, but it comes at a steep cost. Wear on both the grinding media and the mill's internal liner increases exponentially with speed. A slightly lower speed can often result in a much longer operational life for components with only a marginal decrease in throughput.

Coarse vs. Fine Grinding

The setup for coarse and fine grinding is fundamentally different. Large, heavy media excellent for breaking down 1-inch rocks are highly inefficient at producing sub-micron particles. Conversely, a mill charged with tiny ceramic beads for fine grinding will be unable to process coarse feed material effectively. You must choose one priority.

Charge Volume vs. Mill Capacity

While a higher charge volume (e.g., 45%) increases the grinding action, it leaves less physical space inside the mill for the actual material being processed. This can reduce the mill's throughput or require a batch-style operation.

Making the Right Choice for Your Goal

Your optimal setup depends entirely on your primary objective. Use these principles as a starting guide.

- If your primary focus is rapid size reduction of coarse material: Prioritize impact forces by using high-density steel balls, a larger media size relative to the feed, and a rotational speed in the 70-75% range of critical.

- If your primary focus is achieving an ultra-fine particle size: Prioritize attrition by using smaller media to maximize surface area, a lower rotational speed (around 65% of critical), and potentially a longer grinding duration.

- If your primary focus is preventing product contamination: Your choice is clear—use ceramic or flint media and ensure the mill liner is made of a compatible, non-shedding material.

Mastering these interconnected factors transforms ball milling from a brute-force process into a precise and controllable engineering tool.

Summary Table:

| Factor | Key Influence | Optimal Range / Considerations |

|---|---|---|

| Mill Rotational Speed | Balance of impact vs. attrition forces | 65-75% of critical speed for most applications |

| Grinding Media | Impact force and grinding mechanism | Steel for hard materials, Ceramic for contamination-free grinding |

| Material Characteristics | Required force and media selection | Hardness, toughness, and initial feed size are critical |

| Filling Ratio (Charge Volume) | Grinding efficiency and mill capacity | Typically 30-50% of mill volume |

Struggling to achieve the right particle size or improve your milling efficiency? The experts at KINTEK are here to help. We specialize in providing laboratory equipment and consumables, including ball mills and grinding media tailored to your specific material and application. Whether your goal is rapid coarse grinding or achieving an ultra-fine powder without contamination, we can help you optimize your process. Contact our technical team today for a personalized consultation and let us help you master your milling process.

Visual Guide

Related Products

- High Energy Planetary Ball Mill Machine for Laboratory Horizontal Tank Type

- Mini Planetary Ball Mill Machine for Laboratory Milling

- Liquid Nitrogen Cryogenic Grinder Mill Cryomill Airflow Ultrafine Pulverizer

- Small Injection Molding Machine for Lab Use

- Metallographic Specimen Mounting Machine for Laboratory Materials and Analysis

People Also Ask

- How does a planetary ball mill enhance the electrocatalytic activity of La0.6Sr0.4CoO3-δ? Boost Your Catalyst Performance

- What is the specific role of a high-energy planetary ball mill in the synthesis of Ag-doped sulfide solid-state electrolytes?

- What is the role of a planetary ball mill in the synthesis of Li2S–P2S5 sulfide solid-state electrolytes?

- What is the function of a high-energy planetary ball mill in zirconium-doped CaO synthesis? Optimize Material Stability

- What is the function of a high-energy planetary ball mill in the synthesis of iodo-vanadate-lead ceramic waste forms?