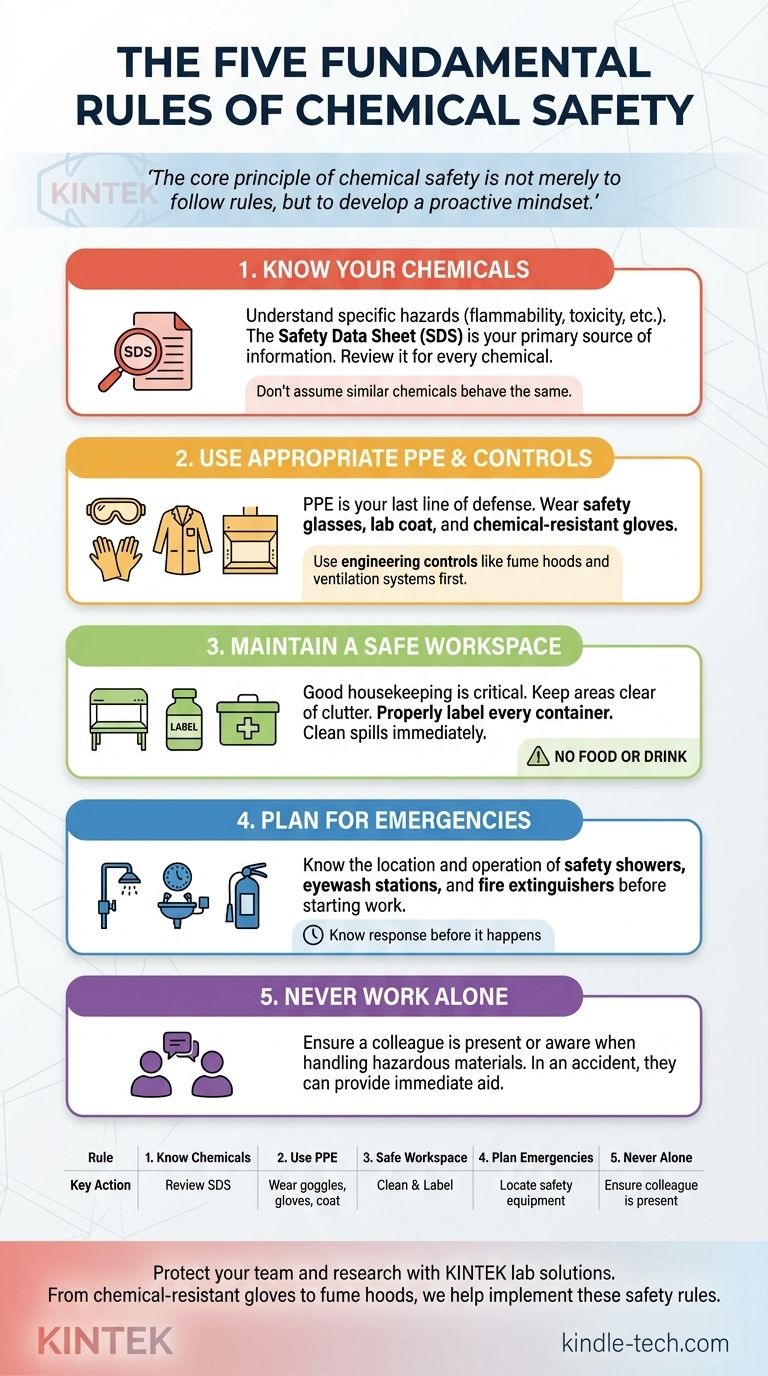

The five fundamental rules of chemical safety are to know your materials, use proper protection, maintain a safe environment, follow correct procedures, and always plan for emergencies. These principles form a comprehensive system for mitigating risk, moving beyond a simple checklist to create a deeply ingrained culture of safety.

The core principle of chemical safety is not merely to follow rules, but to develop a proactive mindset. It's a continuous cycle of assessing risk, implementing controls, and preparing for contingencies before any container is ever opened.

The Foundation: Information and Risk Assessment

True safety begins with knowledge. You cannot protect yourself from a hazard you do not understand. This foundational step involves actively seeking and comprehending the risks associated with every chemical you use.

Rule 1: Know Your Chemicals

Before you begin work, you must understand the specific hazards of the substances involved. This includes their flammability, reactivity, corrosivity, and toxicity.

Every chemical has a unique profile. Assuming one acid or solvent behaves like another is a dangerous mistake that can lead to unexpected reactions or exposures.

Understanding the Safety Data Sheet (SDS)

The Safety Data Sheet (SDS) is your primary source of information. It is a standardized document that details a chemical's properties and hazards.

The SDS provides critical data on first-aid measures, firefighting procedures, handling and storage requirements, and the necessary personal protective equipment (PPE). It is your most important safety guide.

Establishing a Barrier of Protection

Once you understand the risks, the next step is to place effective barriers between yourself and the chemical hazards. This involves both personal equipment and engineering controls.

Rule 2: Use Appropriate Personal Protective Equipment (PPE)

PPE is your last line of defense against exposure. The minimum requirement in most settings is safety glasses or goggles, a lab coat, and closed-toe shoes.

However, the specific hazards dictate additional needs. The SDS will specify the correct type of gloves, as a standard nitrile glove may not protect against certain solvents. Respirators may also be required for volatile or highly toxic substances.

The Role of Engineering Controls

Engineering controls, such as fume hoods and proper ventilation systems, are designed to remove or contain the hazard at its source.

These systems are your first and most effective line of defense. Always ensure they are functioning correctly before starting work. PPE is designed to protect you from what the engineering controls cannot contain.

Controlling Your Immediate Environment

A clean, organized, and well-managed workspace is fundamental to preventing accidents like spills, cross-contamination, and fires.

Rule 3: Maintain a Safe and Controlled Workspace

Good housekeeping is a critical safety discipline. Keep work areas clear of clutter, immediately clean up all spills, and ensure aisles and emergency exits are never obstructed.

Properly label every container, including temporary beakers and flasks. An unlabeled chemical is an unknown and therefore an unacceptable hazard.

Follow Proper Procedures for Handling and Storage

Never eat, drink, or chew gum in an area where chemicals are used. Always wash your hands thoroughly after handling any chemical, even if you were wearing gloves.

Chemicals must be stored according to their compatibility. For example, flammables should be stored in a dedicated cabinet, and strong acids must never be stored with bases or cyanides.

Understanding the Pitfalls: Complacency and Unpreparedness

The single greatest threat to chemical safety is not a specific substance, but the human tendency toward complacency. This is why planning for failure is a non-negotiable rule.

Rule 4: Always Plan for Emergencies

Before you start an experiment, you must know what to do if something goes wrong. Ask yourself: "What is the worst-case scenario, and how will I respond?"

This includes knowing the location and proper operation of emergency showers, eyewash stations, fire extinguishers, and spill kits. In an emergency, you will not have time to look for them.

Rule 5: Never Work Alone

When working with hazardous materials, it is critical to have another person present or within earshot who is aware of the work you are doing.

In the event of an incapacitating accident, this person can provide immediate aid and call for emergency assistance.

Making the Right Choice for Your Goal

- If your primary focus is daily lab work: Make it a habit to review the SDS for every new chemical and verify that engineering controls like fume hoods are working before you begin.

- If your primary focus is managing a team or facility: Prioritize training and ensure that emergency equipment is regularly inspected and accessible, fostering a culture where safety concerns are openly reported.

- If your primary focus is occasional chemical use: Always wear the minimum appropriate PPE (goggles, gloves) and ensure you are working in a well-ventilated area, even for seemingly simple tasks.

Ultimately, chemical safety is an active, continuous process of respect for the materials you handle.

Summary Table:

| Rule | Key Action |

|---|---|

| 1. Know Your Chemicals | Review the Safety Data Sheet (SDS) for every chemical. |

| 2. Use Appropriate PPE | Wear safety glasses, lab coat, and chemical-resistant gloves. |

| 3. Maintain a Safe Workspace | Keep the area clean, label all containers, and use fume hoods. |

| 4. Plan for Emergencies | Know the location of safety showers, eyewash stations, and spill kits. |

| 5. Never Work Alone | Ensure a colleague is present or aware when handling hazardous materials. |

Protect your team and your research with the right equipment and support.

KINTEK specializes in providing the essential lab equipment and consumables that form the foundation of a safe laboratory—from chemical-resistant gloves and safety goggles to fume hoods and proper storage solutions. Our expertise helps you implement these five critical safety rules effectively.

Ready to enhance your lab's safety culture? Contact our safety specialists today to discuss your specific needs and ensure your lab is equipped for success and safety.

Visual Guide

Related Products

- Laboratory Manual Hydraulic Pellet Press for Lab Use

- Double Layer Five-Port Water Bath Electrolytic Electrochemical Cell

- Customizable High Pressure Reactors for Advanced Scientific and Industrial Applications

- Optical Ultra-Clear Glass Sheet for Laboratory K9 B270 BK7

- 5L Heating Chilling Circulator Cooling Water Bath Circulator for High and Low Temperature Constant Temperature Reaction

People Also Ask

- Does graphite shrink? The Critical Role of Temperature and Radiation in Dimensional Stability

- What is the HIP process in casting? Achieve Dense, High-Performance Metal Components

- What is the effect of sintering in powder metallurgy? Transforming Powder into Strong, Functional Parts

- What are the three sample preparation techniques? Master the Key Stages for Accurate Analysis

- What is a disadvantage of biomass energy? The Hidden Environmental and Economic Costs

- What is sintering in ceramic? The High-Temperature Process for Creating Dense, Strong Materials

- What is DFT coating thickness? Ensure Quality and Performance with Precise Measurement

- Is XRF testing Qualitative or quantitative? Unlocking Its Dual Role in Elemental Analysis