The primary liquid product of pyrolysis is a complex substance known as bio-oil. This dark, viscous liquid, sometimes referred to as pyrolysis oil or wood acid, is formed by cooling and condensing the hot gases and vapors released when organic material is heated in an oxygen-free environment. The other main products of the process are a solid material called biochar and non-condensable gases.

Bio-oil is more than just a byproduct; it is a transportable liquid energy carrier and a potential source of renewable chemicals. However, its exact composition and utility are directly tied to the type of material being processed and the specific pyrolysis conditions used.

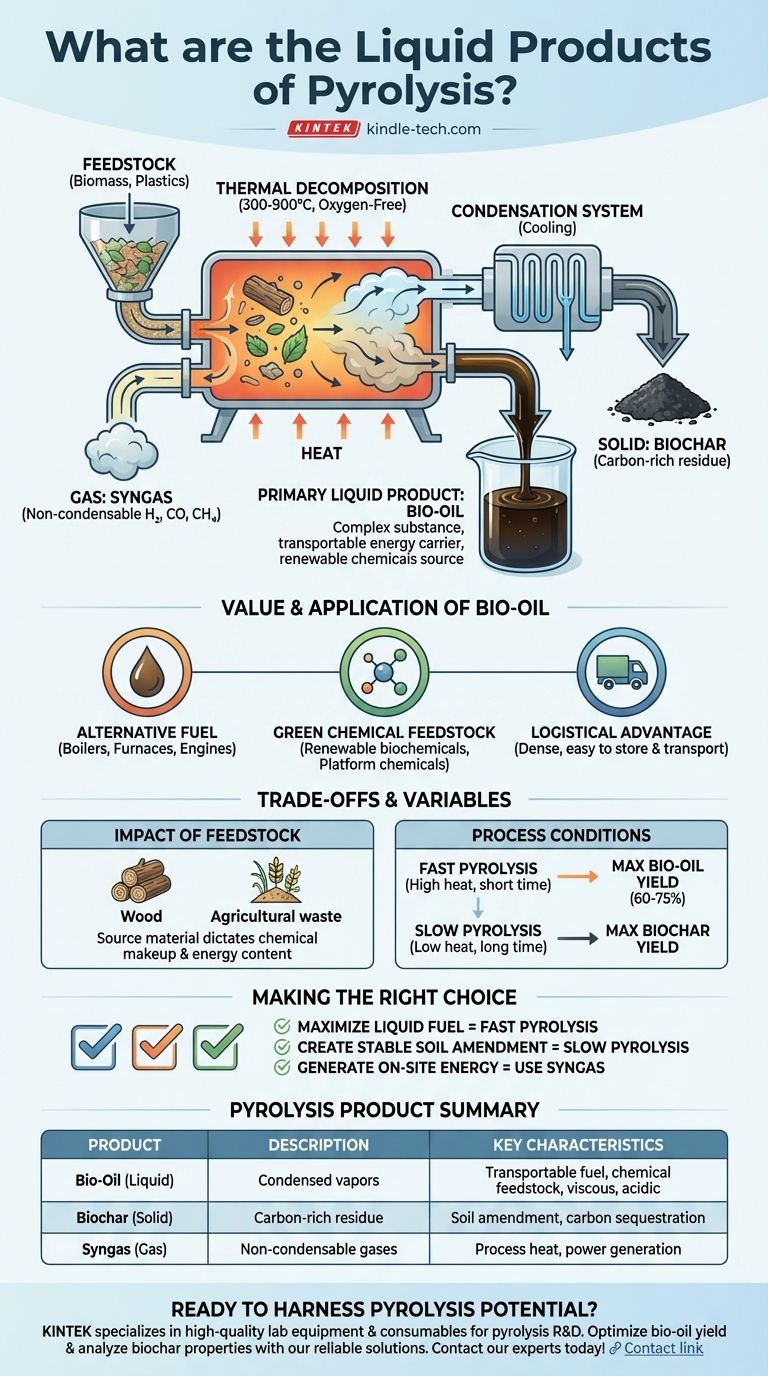

What is Pyrolysis and How is Liquid Product Formed?

To understand the liquid output, you must first understand the core process that creates it. Pyrolysis is a method of thermal decomposition that breaks down complex materials.

The Core Process: Thermal Decomposition

Pyrolysis involves heating organic materials, such as biomass or plastics, to high temperatures (typically 300-900°C) in a container with little to no oxygen. The absence of oxygen is critical; it ensures the material breaks down chemically without combusting (burning).

From Vapor to Liquid: Condensation is Key

The intense heat vaporizes the volatile components of the feedstock, turning them into a hot gas mixture. This gas is then passed through a cooling system.

As the gas cools, certain components condense back into a liquid state, which is collected as bio-oil. The remaining components that do not condense form the non-condensable gas fraction, or syngas.

The Three Primary Outputs

Ultimately, the process separates the initial feedstock into three distinct product streams:

- Liquid (Bio-oil): The condensed vapors, rich in various organic compounds.

- Solid (Biochar): The remaining carbon-rich solid material.

- Gas (Syngas): The non-condensable gases like hydrogen, methane, and carbon monoxide.

The Value and Application of Bio-Oil

Bio-oil is gaining significant attention because it transforms bulky solid biomass into a liquid that is much easier to handle.

An Alternative Fuel Source

Bio-oil can be used directly as a fuel for industrial boilers, furnaces, and even some specialized engines and turbines to generate heat or electricity.

A Feedstock for Green Chemicals

The liquid is a complex mixture of hundreds of organic compounds. This makes it a valuable feedstock for producing renewable "biochemicals," platform chemicals, and other high-value products after further refining.

The Logistical Advantage

Perhaps its most significant advantage is logistical. Unlike heat or gas, a liquid is dense and easy to store and transport. This allows biomass from a rural area to be converted into a portable fuel that can be used elsewhere.

Understanding the Trade-offs and Variables

The term "bio-oil" describes a broad category of liquids, not a single, uniform substance. Its quality and usefulness depend entirely on several key factors.

The Impact of Feedstock

The material you start with dictates the final product. Bio-oil from wood will have a different chemical makeup and energy content than bio-oil produced from agricultural waste or plastics.

The Role of Process Conditions

The yield of each product fraction depends heavily on the process parameters.

- Fast Pyrolysis: Uses very high heating rates and short residence times to maximize the production of liquid bio-oil (often 60-75% yield by weight).

- Slow Pyrolysis: Uses low heating rates over several hours. This process is optimized to maximize the solid biochar yield.

The Challenge of "Upgrading"

Raw bio-oil is often acidic, corrosive, and chemically unstable, and it contains a significant amount of water. For many applications, especially as a transportation fuel, it must undergo further processing—known as "upgrading"—to improve its properties.

Making the Right Choice for Your Goal

The "best" pyrolysis setup depends entirely on which product you value most.

- If your primary focus is maximizing liquid fuel production: Fast pyrolysis is the ideal method, as it is specifically designed to convert the highest possible percentage of biomass into bio-oil.

- If your primary focus is creating a stable soil amendment: Slow pyrolysis is the preferred route, as its goal is to maximize the output of solid, carbon-rich biochar.

- If your primary focus is generating on-site energy with minimal waste: The non-condensable gases (syngas) produced can be captured and burned to provide the energy needed to run the pyrolysis process itself, creating a self-sustaining system.

Understanding the relationship between the pyrolysis process and its distinct outputs is the key to unlocking the full potential of your chosen feedstock.

Summary Table:

| Pyrolysis Product | Description | Key Characteristics |

|---|---|---|

| Bio-Oil (Liquid) | Condensed vapors from pyrolysis. | Transportable fuel, chemical feedstock, viscous and acidic. |

| Biochar (Solid) | Carbon-rich solid residue. | Soil amendment, carbon sequestration. |

| Syngas (Gas) | Non-condensable gases (e.g., H₂, CO). | Can be used for process heat or power generation. |

Ready to harness the potential of pyrolysis for your laboratory or project? KINTEK specializes in high-quality lab equipment and consumables for pyrolysis research and development. Whether you're optimizing bio-oil yield from biomass or analyzing biochar properties, our reliable solutions help you achieve precise and reproducible results. Contact our experts today to discuss how we can support your specific laboratory needs!

Visual Guide

Related Products

- Electric Rotary Kiln Continuous Working Small Rotary Furnace Heating Pyrolysis Plant

- Custom PTFE Teflon Parts Manufacturer for PTFE Mesh F4 Sieve

- FS Electrochemical Hydrogen Fuel Cells for Diverse Applications

- Laboratory High Pressure Horizontal Autoclave Steam Sterilizer for Lab Use

- Desktop Fast Laboratory Autoclave Sterilizer 35L 50L 90L for Lab Use

People Also Ask

- How does a rotary extractor work? Master Continuous High-Volume Solid Processing

- What is the meaning of rotary furnace? Achieve Superior Uniformity in Continuous Heat Treatment

- What is the drying zone in a rotary kiln? Boost Efficiency with Modern Drying Solutions

- What are the zones in rotary kiln in cement production? Master the Core Process for High-Quality Clinker

- How is the operational mode of bed motion selected for a rotary kiln? Optimize Heat Transfer and Material Homogeneity