The size of a ball mill varies dramatically, ranging from small laboratory models that fit on a benchtop to massive industrial units that are meters in diameter and length. This vast range exists because the mill's dimensions are fundamentally tied to its specific application, from research and development to large-scale mineral processing.

The critical insight is not the range of available sizes, but understanding that the optimal ball mill size is determined by three key factors: the required material throughput, the initial feed size, and the desired final particle size.

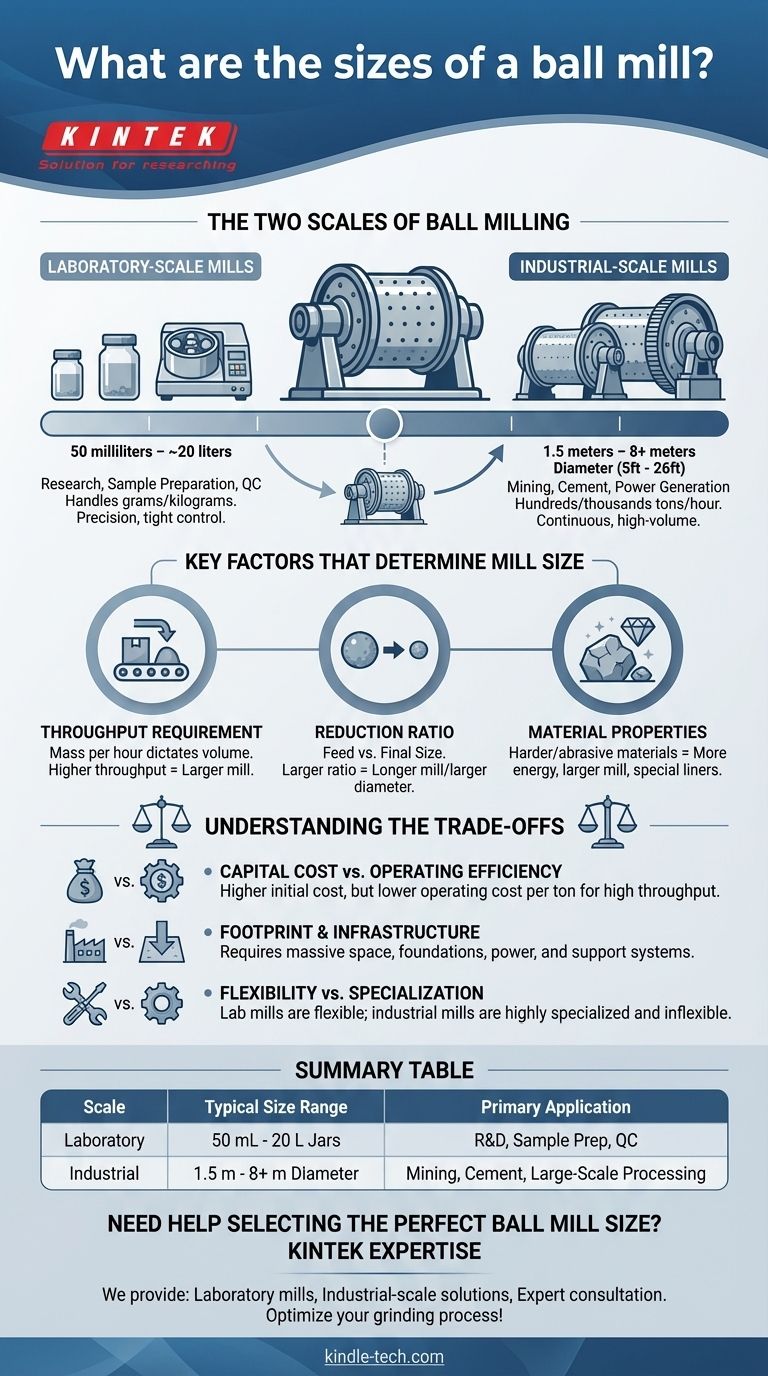

The Two Scales of Ball Milling

The world of ball mills is best understood by dividing it into two distinct categories based on application and scale. Each category serves a different purpose and, consequently, has a completely different size profile.

Laboratory-Scale Mills

Lab-scale ball mills are designed for research, sample preparation, and quality control. They handle very small batches of material, typically measured in grams or a few kilograms.

Their size is defined by the volume of the grinding jars, which can range from just 50 milliliters to around 20 liters. These compact units, such as planetary or vibratory ball mills, are engineered for precision, allowing for tight control over grinding parameters to test material properties.

Industrial-Scale Mills

Industrial mills are the workhorses of industries like mining, cement production, and power generation. They are designed for continuous, high-volume operation, processing hundreds or thousands of tons of material per hour.

Their size is described by their internal diameter and length, which can be enormous—often ranging from 1.5 meters (5 ft) to over 8 meters (26 ft) in diameter. These mills are massive, power-intensive machines requiring significant infrastructure and custom engineering for each installation.

Key Factors That Determine Mill Size

Selecting the correct mill size is a critical engineering decision. It's not an off-the-shelf choice but a calculation based on specific operational needs.

Throughput Requirement

This is the single most important factor for industrial mills. The mass of material to be processed per hour (e.g., tons per hour) directly dictates the necessary volume of the mill. A higher throughput requires a larger mill.

Reduction Ratio

The ratio between the starting feed particle size and the target final particle size heavily influences sizing. A larger reduction ratio means the material must spend more time in the mill, which may necessitate a longer mill or a larger diameter to achieve the desired output.

Material Properties

The characteristics of the material being ground are crucial. Harder and more abrasive materials require more energy and time to break down. This often means a larger, more powerful mill is needed to maintain the desired throughput compared to a softer material. This also influences the choice of internal liners, which must be abrasion-resistant.

Understanding the Trade-offs

Choosing a mill size involves balancing competing priorities. An oversized or undersized mill will lead to significant operational inefficiencies.

Capital Cost vs. Operating Efficiency

Larger mills have a substantially higher initial purchase and installation cost. However, for high-throughput operations, they often provide a lower operating cost per ton of processed material, delivering crucial economies of scale.

Footprint and Infrastructure

An industrial ball mill is not a standalone piece of equipment. It requires a massive concrete foundation, powerful electric motors, gearboxes, and sophisticated feeding and discharge systems. The physical space and supporting infrastructure are a primary constraint on size selection.

Flexibility vs. Specialization

Laboratory mills offer tremendous flexibility to test different materials, grinding media, and speeds. In contrast, industrial mills are highly specialized and optimized for a single, continuous process. They are efficient but entirely inflexible.

Selecting the Right Scale for Your Application

Your final choice must be aligned with your ultimate goal, whether it's discovery, testing, or full-scale production.

- If your primary focus is research and development: A laboratory-scale mill with interchangeable jar sizes (e.g., 250 mL to 2 L) provides the necessary flexibility for experimentation.

- If your primary focus is pilot-scale testing: A larger benchtop or small pilot plant mill (e.g., 20 to 100 L capacity) is needed to validate processes before committing to industrial-scale investment.

- If your primary focus is large-scale manufacturing: Sizing requires a formal engineering study, including lab testing of your material to determine its grinding properties and precise modeling to match throughput goals.

Ultimately, choosing the right ball mill size is a direct function of your operational goals and material characteristics.

Summary Table:

| Scale | Typical Size Range | Primary Application |

|---|---|---|

| Laboratory | 50 mL - 20 L Jars | R&D, Sample Preparation, Quality Control |

| Industrial | 1.5 m - 8+ m Diameter | Mining, Cement, Large-Scale Mineral Processing |

Need Help Selecting the Perfect Ball Mill Size for Your Lab?

Choosing the right ball mill is critical for your research or production efficiency. Whether you need a precise benchtop model for R&D or are planning a large-scale industrial installation, KINTEK has the expertise and equipment to match your specific requirements.

We provide:

- Laboratory ball mills for precise sample preparation and material testing

- Industrial-scale solutions engineered for high-throughput mineral processing

- Expert consultation to analyze your material properties, throughput needs, and desired particle size

Let our specialists help you optimize your grinding process—contact us today for a personalized recommendation!

Visual Guide

Related Products

- Stainless Steel Laboratory Ball Mill for Dry Powder and Liquid with Ceramic Polyurethane Lining

- Laboratory Ball Mill Jar Mill with Metal Alloy Grinding Jar and Balls

- High-Energy Omnidirectional Planetary Ball Mill Machine for Laboratory

- High Energy Planetary Ball Mill Milling Machine for Laboratory

- High-Energy Omnidirectional Planetary Ball Mill Milling Machine for Laboratory

People Also Ask

- What is the specific function of a planetary ball mill in preparing Cr-50 wt% Si alloy? Master Mechanical Alloying

- Why is secondary ball milling necessary for sulfur cathodes? Master Solid-State Electrolyte Composite Preparation

- Why is a ball mill required to process synthesized Ti2AlN? Achieve Superior Sintering Density and Uniformity

- What role does high-energy ball milling equipment play in ODS FeCrAl production? Maximize Alloy Performance

- What is the key role of a planetary ball mill in CCCs? Precision Mechanical Alloying for Advanced Carbide Ceramics

- What role do zirconia grinding jars and balls play in mixing ZrB2-SiC powders? Ensure Purity and Homogeneity

- What is the primary role of high-energy ball milling in UO2-BeO fuel? Master Homogenization for Nuclear Power

- Why are zirconia grinding balls selected for milling NaSICON? Optimize Your Solid Electrolyte Purity and Performance