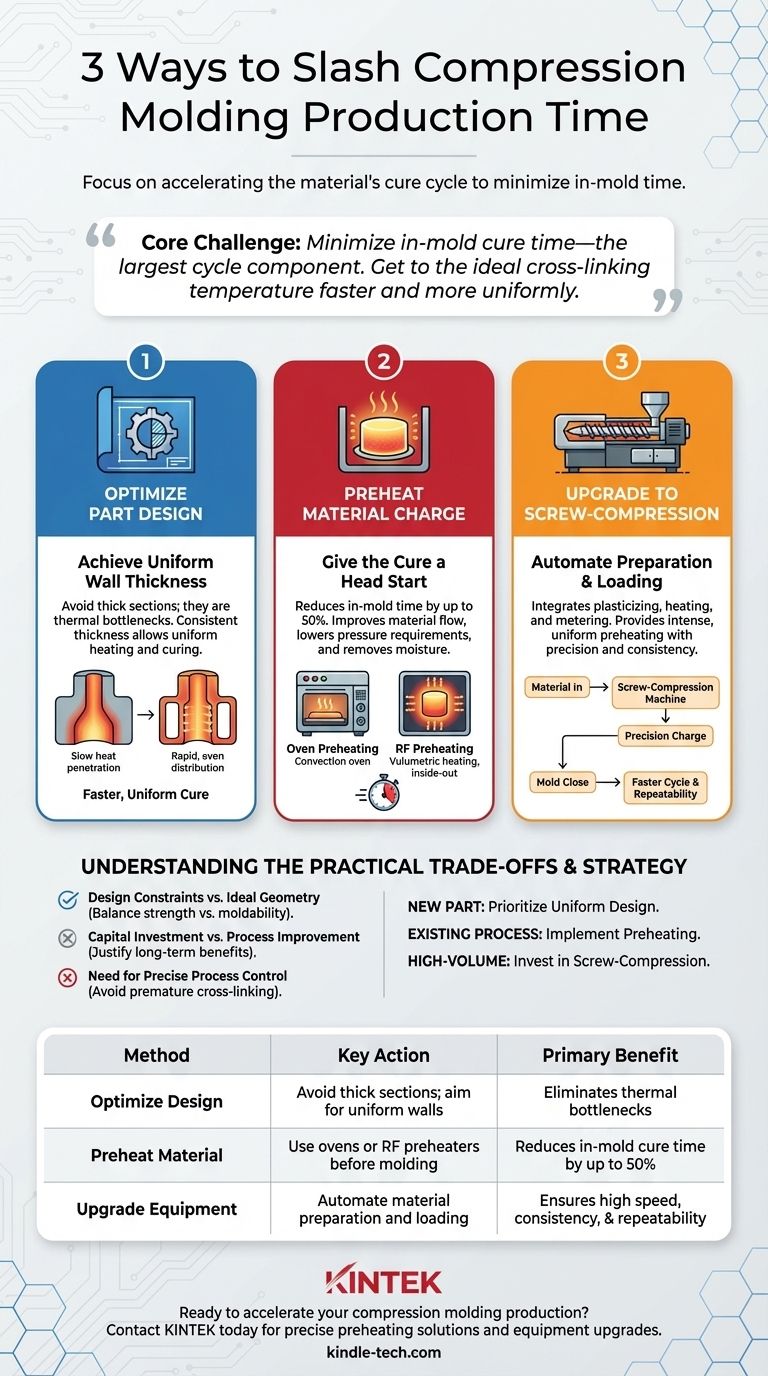

To reduce production time in compression molding, you must focus on accelerating the material's cure cycle. The three most effective methods are optimizing the part design by avoiding thick sections, preheating the material charge before it enters the mold, and utilizing modern screw-compression equipment for automated preparation and loading.

The core challenge in compression molding is minimizing the in-mold cure time, which is the largest component of any cycle. Every effective time-saving strategy is ultimately about getting the thermoset material to its ideal cross-linking temperature faster and more uniformly.

Optimizing Part Design for Faster Curing

The physical geometry of a part is the most fundamental factor controlling its production speed. Because thermoset plastics are poor thermal conductors, heat transfer is a slow process.

The Problem with Thick Sections

Thick sections act as a thermal bottleneck. The exterior of the part heats up and begins to cure, but it takes significantly longer for heat to penetrate to the core of a thick area.

The entire cycle is held hostage by the slowest-curing part of the component. You cannot open the mold until the thickest section is fully cured, leading to wasted time where the rest of the part is waiting.

The Principle of Uniform Wall Thickness

The ideal part design for compression molding maintains a consistent wall thickness throughout. This allows the entire part to heat up and cure at a uniform rate.

When thick sections are unavoidable, design techniques like "coring out" the area can remove unnecessary material, creating a more uniform cross-section without compromising structural integrity.

Accelerating the Cycle with Material Preheating

Heating the material before it enters the hot mold is one of the most direct ways to shorten the production cycle. You are essentially giving the curing process a head start.

How Preheating Reduces In-Mold Time

A preheated material charge requires less time and energy from the mold to reach its final cure temperature. This can slash the in-mold cure time by 50% or more.

Preheating also improves material flow, reduces the required molding pressure, and helps drive off any residual moisture, which can prevent surface defects.

Common Preheating Techniques

The most common methods include placing the material charge in a convection oven or using a high-frequency (RF) preheater.

RF preheating is particularly efficient as it heats the material volumetrically (from the inside out), resulting in a very uniform temperature throughout the charge.

Upgrading Equipment for Automated Efficiency

Modern machinery integrates material preparation directly into the molding process, eliminating manual steps and creating a more consistent, faster cycle.

The Role of Screw-Compression Machinery

Screw-compression (or screw injection) molding machines use a reciprocating screw, similar to an injection molding press. This screw automatically plasticizes, heats, and meters the exact amount of material needed.

The screw's shearing action provides intense, uniform heating to the material before it's delivered to the mold. This effectively automates the preheating process with a high degree of precision.

The Impact on Material Handling and Consistency

Automating the material preparation and dosing process eliminates the variability of manual loading. This leads to a more repeatable process, reduced material waste, and a consistently shorter cycle time.

Understanding the Practical Trade-offs

While these methods are effective, they come with practical considerations that must be balanced against your specific operational goals.

Design Constraints vs. Ideal Geometry

A designer's goal is to achieve uniform wall thickness, but the functional requirements of the part may demand a thick section for strength or assembly. This requires a compromise between ideal moldability and end-use performance.

Capital Investment vs. Process Improvement

Preheating equipment and especially new screw-compression machinery require significant capital investment. This must be justified by the expected increase in throughput and reduction in part cost over the long term.

The Need for Precise Process Control

Preheating is not without risk. Overheating the material can initiate the cross-linking reaction prematurely, causing the material to set up before the mold is closed. This requires precise control over temperature and time to be effective.

How to Apply This to Your Production Goals

Your strategy for reducing cycle time depends on your resources and where you are in the product lifecycle.

- If your primary focus is designing a new part: Prioritize creating a uniform wall thickness and core out any unavoidable thick sections from the start.

- If your primary focus is improving an existing process with minimal investment: Implement a controlled preheating step for your material charge.

- If your primary focus is maximizing long-term, high-volume production: Invest in screw-compression machinery to automate the process for the highest possible speed and consistency.

Ultimately, mastering compression molding efficiency comes from controlling heat transfer with intention and precision.

Summary Table:

| Method | Key Action | Primary Benefit |

|---|---|---|

| Optimize Part Design | Avoid thick sections; aim for uniform wall thickness | Eliminates thermal bottlenecks for uniform curing |

| Preheat Material Charge | Use ovens or RF preheaters before molding | Reduces in-mold cure time by up to 50% |

| Upgrade to Screw-Compression | Automate material preparation and loading | Ensures high speed, consistency, and repeatability |

Ready to accelerate your compression molding production?

At KINTEK, we specialize in providing the lab equipment and consumables that help you optimize your processes. Whether you need precise preheating solutions or are considering an upgrade to modern screw-compression machinery, our experts can help you identify the right strategy to maximize your throughput and consistency.

Contact our team today to discuss how we can help you achieve faster cycle times and lower part costs.

Visual Guide

Related Products

- Rubber Vulcanizer Vulcanizing Machine Plate Vulcanizing Press for Lab

- Small Injection Molding Machine for Lab Use

- Single Punch Electric Tablet Press Machine Laboratory Powder Tablet Punching TDP Tablet Press

- Double Plate Heating Press Mold for Lab

- Lab Plastic PVC Calender Stretch Film Casting Machine for Film Testing

People Also Ask

- Which forging press would be best for producing very large parts? Unmatched Force for Massive Components

- Can a hydraulic press shatter a diamond? Yes, and here's why hardness isn't toughness.

- What is the primary function of laboratory hydraulic presses? Prepare High-Precision Carbide Samples for Research

- What is an automatic press machine? High-Precision Force for Modern Manufacturing

- What is a growth cell and what are its essential components in the HPHT process? Master Diamond Synthesis Core

- Can you use a hydraulic press for forging? Power, Precision, and Deep Deformation

- What is the primary purpose of using a laboratory hydraulic press at 500 MPa? Optimize Solid-State Battery Density

- What function does a laboratory hydraulic press perform in the preparation of solid-state battery electrolyte layers?