In short, sieving separates heterogeneous mixtures composed of solid particles of different sizes. This simple yet effective technique is used across countless fields for materials ranging from common soils and construction aggregates to fine powders in the food and chemical industries. The key requirement is that the components you wish to separate must have a noticeable size difference.

The effectiveness of sieving does not depend on the chemical nature of the substances, but on a simple physical property: a significant difference in the size of the component particles.

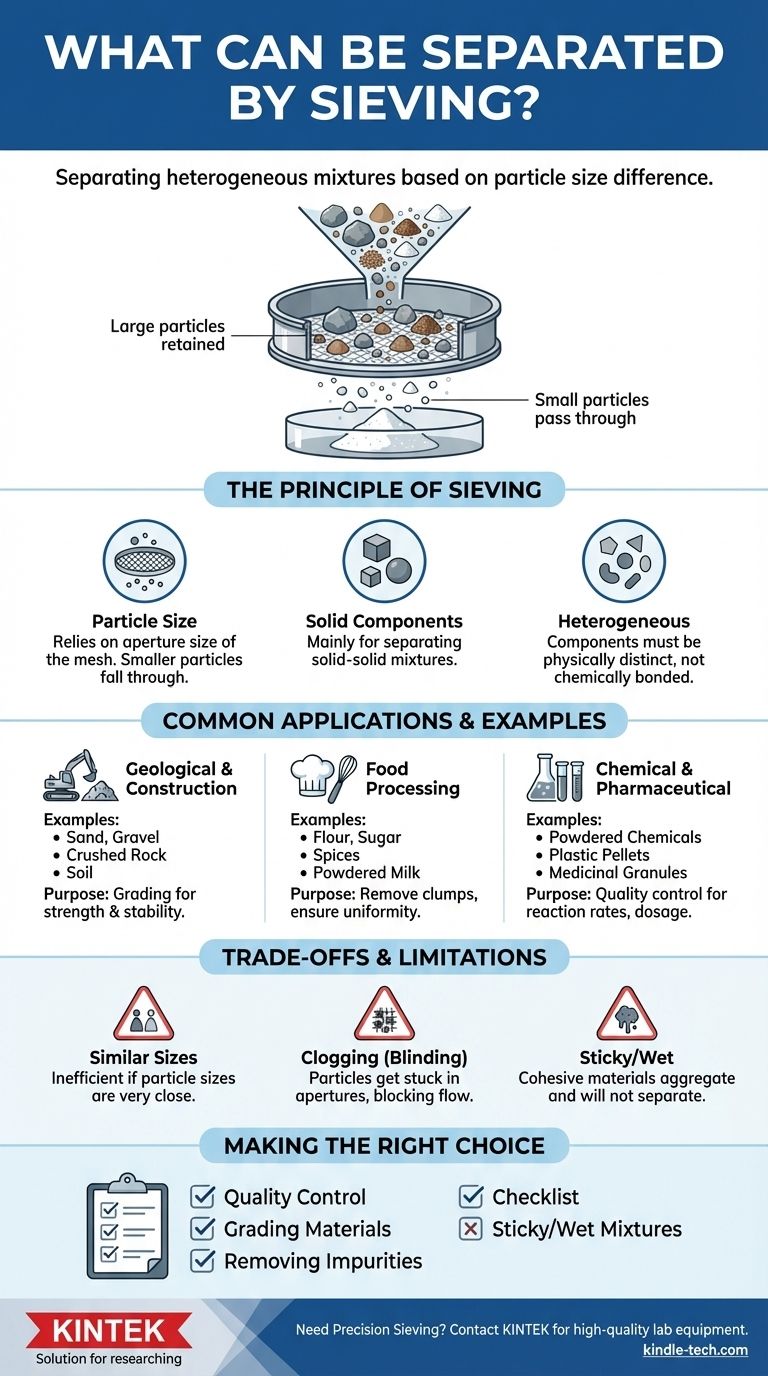

The Fundamental Principle of Sieving

To understand what can be sieved, you must first grasp the core mechanism. Sieving is a method of mechanical separation, not a chemical one.

It's All About Particle Size

A sieve is essentially a mesh or screen with openings of a uniform size, known as apertures. When a mixture is passed over it, particles smaller than the apertures fall through, while particles larger than the apertures are retained.

The Components Must Be Solid

Sieving is primarily used to separate a mixture of two or more solids. It can also be used to separate a solid from a liquid it is suspended in (like straining pulp from juice), but its main industrial application is for solid-solid separation.

The Mixture Must Be Heterogeneous

This means the components are physically distinct and not chemically bonded or dissolved. For example, you can sieve a mixture of sand and small pebbles, but you cannot sieve salt that has been dissolved in water.

Common Applications and Material Examples

The principle of sieving is applied to an incredibly wide array of materials. The examples provided in an analysis context—sands, soils, construction materials, food, and chemicals—highlight its versatility.

Geological and Construction Materials

In this field, sieving is often called "grading." It is essential for ensuring materials meet specific standards for strength and stability.

Examples include separating sand, gravel, crushed rock, and soil into different size classifications for use in concrete, asphalt, or foundational layers.

Food Processing

Consistency in texture and quality is paramount in the food industry. Sieving is used to remove clumps, aerate powders, and ensure a uniform final product.

Common materials include flour, sugar, salt, spices, and powdered milk. It is also used to separate solids like seeds from fruit purees.

Chemical and Pharmaceutical Industries

Particle size can dramatically affect the reaction rate, dissolution speed, and dosage uniformity of chemical and pharmaceutical products.

Sieving is critical for quality control of powdered chemicals, plastic pellets, and medicinal granules to ensure they meet strict manufacturing specifications.

Understanding the Trade-offs and Limitations

While powerful, sieving is not a universal solution. Its effectiveness is limited by the physical properties of the materials being separated.

When Particle Sizes are Too Similar

If the particles in a mixture are very close in size, it becomes difficult for the sieve to effectively distinguish and separate them. The process becomes inefficient or fails entirely.

The Problem of Clogging (Blinding)

Particles that are very close to the size of the sieve's apertures can get stuck in the mesh. This phenomenon, known as blinding, blocks the openings and stops the separation process.

Sticky or Wet Materials

Cohesive materials that tend to clump together will not separate properly. Even if individual particles are small enough to pass through, they will aggregate into larger masses and be retained on the sieve.

Static Electricity with Fine Powders

Very fine, dry powders can develop a static charge from the friction of sieving. This causes particles to cling to each other and the sieve mesh, hindering separation.

Making the Right Choice for Your Goal

Deciding whether sieving is the appropriate method depends entirely on the physical characteristics of your mixture and your desired outcome.

- If your primary focus is quality control in an industrial setting: Sieving is the standard for verifying particle size distribution in raw materials and finished products like powders, aggregates, and granules.

- If your primary focus is grading materials for construction or landscaping: Sieving is the essential method for separating sand, gravel, and soil into the required size classes.

- If your primary focus is removing impurities or clumps: Sieving is a simple and effective way to ensure uniformity in materials like flour or to separate unwanted solids like seeds from a pulp.

- If your mixture's particles are sticky, wet, or extremely close in size: You should investigate alternative separation methods, as sieving will likely be ineffective or highly inefficient.

Ultimately, understanding the physical properties of your mixture is the key to successfully applying this powerful and straightforward separation technique.

Summary Table:

| Material Category | Common Examples | Primary Purpose |

|---|---|---|

| Geological & Construction | Sand, gravel, crushed rock, soil | Grading for strength and stability standards |

| Food Processing | Flour, sugar, spices, powdered milk | Remove clumps, ensure texture uniformity |

| Chemical & Pharmaceutical | Powdered chemicals, plastic pellets, medicinal granules | Quality control for reaction rates and dosage |

Need Precision Sieving for Your Materials?

Whether you're in construction, food processing, or chemical manufacturing, achieving accurate particle size separation is critical for product quality and consistency. KINTEK specializes in high-quality lab equipment, including precision sieves and shakers, designed to meet the rigorous demands of particle analysis.

Our solutions help you:

- Ensure your materials meet strict industry specifications

- Improve quality control processes with reliable, repeatable results

- Optimize your production efficiency with the right separation tools

Let our experts help you select the perfect sieving equipment for your specific application. Contact KINTEK today for a personalized consultation!

Visual Guide

Related Products

- Laboratory Test Sieves and Vibratory Sieve Shaker Machine

- Laboratory Vibratory Sieve Shaker Machine for Dry and Wet Three-Dimensional Sieving

- Laboratory Vibratory Sieve Shaker Machine Slap Vibrating Sieve

- Vibratory Sieve Shaker Machine Dry Three-Dimensional Vibrating Sieve

- Laboratory Vortex Mixer Orbital Shaker Multifunctional Rotation Oscillation Mixer

People Also Ask

- What are the disadvantages of sieve machine? Key Limitations in Particle Size Analysis

- Why use a vibratory sieve shaker for PET powder? Achieve Precise Particle Size Control for Chemical Research

- What function does a sieving system perform during HPS powder pretreatment? Ensure Uniform Particle Size Distribution

- Why is a laboratory sieving system required for bentonite in coatings? Ensure Flawless Surface Performance

- How do high-precision sieving systems benefit zeolite preparation? Maximize Adsorption for Wastewater Treatment