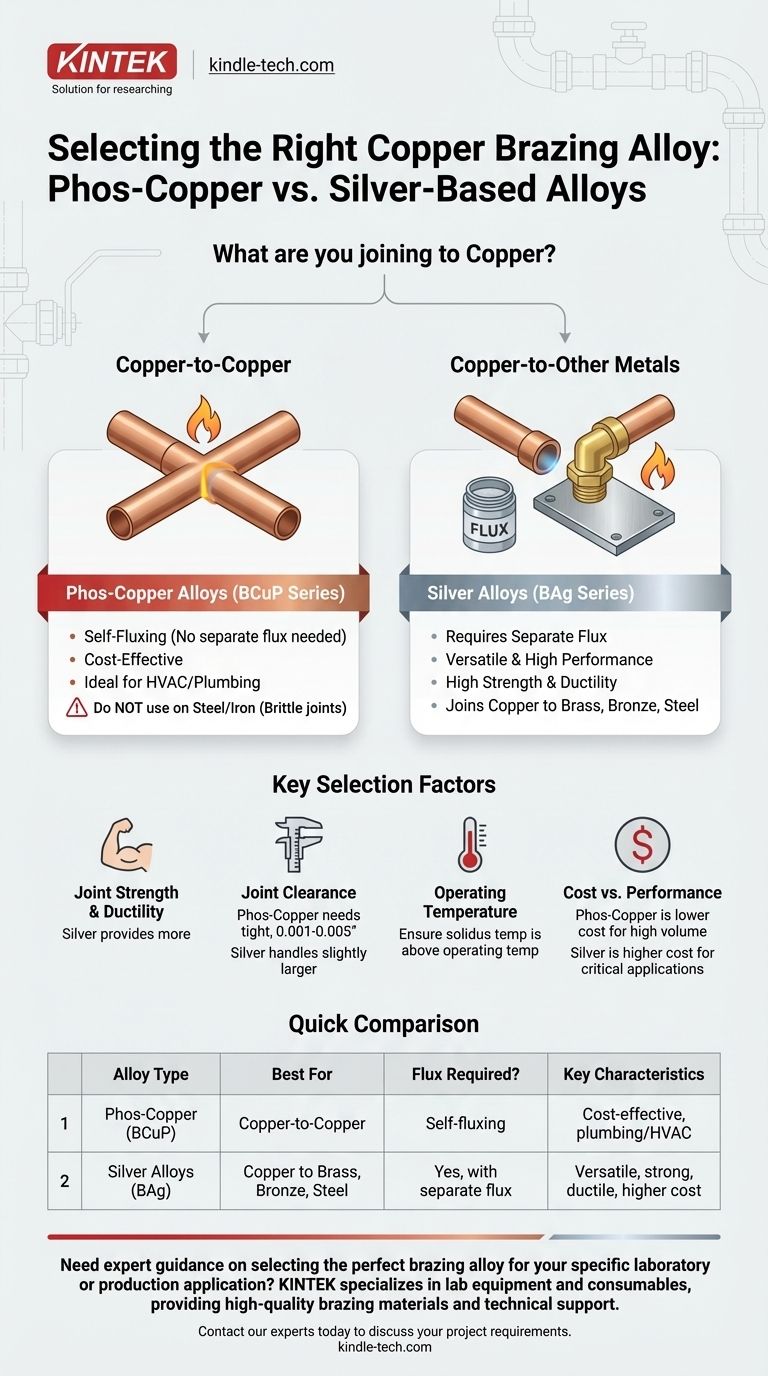

For brazing copper, your primary choices are phosphorus-copper alloys (often called phos-copper or BCuP) for copper-to-copper joints, and silver-based alloys (BAg) for joining copper to other metals like brass, bronze, or steel. Phos-copper alloys are cost-effective and self-fluxing on copper, while silver alloys offer greater versatility, strength, and ductility but require a separate flux.

The most critical factor in your decision is not the copper itself, but the other metal in the joint. For copper-to-copper, a phos-copper alloy is the standard. For copper-to-anything-else, a silver-based alloy with flux is required.

The Two Primary Alloy Families for Copper

When selecting a brazing alloy for copper, you are making a choice between two main categories, each with distinct properties and ideal use cases.

Phos-Copper Alloys (BCuP Series)

Phos-copper alloys are the workhorse for joining copper to itself, commonly seen in plumbing and HVAC applications. Their composition is primarily copper and phosphorus, with some containing a small amount of silver.

The defining feature of this family is that the phosphorus acts as a fluxing agent when joining copper to copper. This "self-fluxing" capability eliminates the need for a separate flux paste, simplifying the process and reducing cost.

Common examples include BCuP-2 (0% silver) and BCuP-5 (15% silver). The addition of silver lowers the melting point and improves the alloy's flow and ductility.

Silver Alloys (BAg Series)

Silver-based brazing alloys are known for their versatility and high performance. They are essential for joining copper to dissimilar metals, such as brass, bronze, steel, and stainless steel.

These alloys always require a separate flux to clean the base metals and ensure proper wetting and flow. The flux removes oxides from both the copper and the other metal, allowing the filler metal to form a strong metallurgical bond.

The percentage of silver (e.g., BAg-7, which is 56% silver) directly impacts the alloy's melting temperature, flow characteristics, and cost. Higher silver content generally means a lower melting point and better ductility.

Key Factors Driving Your Decision

Beyond the base metals, several engineering considerations will guide you to the optimal alloy for your specific application.

Base Metals Being Joined

This is the most important factor. If you are joining copper-to-copper, a BCuP alloy is your most efficient and economical choice.

If you are joining copper to brass, bronze, or steel, you must use a BAg silver alloy with the appropriate flux.

Required Joint Strength and Ductility

Silver alloys typically produce joints that are stronger and more ductile (able to withstand vibration and thermal expansion) than phos-copper alloys.

For applications subject to high stress, vibration, or wide temperature swings, a silver alloy is the more reliable engineering choice.

Joint Clearance and Fit-Up

The gap between the two pieces being joined, or joint clearance, is critical. BCuP alloys are highly fluid and work best with very tight clearances, typically 0.001" to 0.005".

Silver alloys are slightly more viscous and can successfully fill slightly larger gaps, though tight clearances are always preferred for maximum joint strength.

Operating Temperature of the Final Part

Consider the environment where the brazed component will be used. The brazing filler metal must have a solidus temperature (the point at which it is fully solid) well above the part's maximum operating temperature.

Understanding the Trade-offs and Pitfalls

Objective analysis requires understanding the limitations and potential failure points of each alloy type.

The Critical Phos-Copper Limitation

You must not use BCuP (phos-copper) alloys to braze ferrous metals like steel or iron.

The phosphorus in the alloy reacts with the iron to form a brittle iron phosphide layer at the joint interface. This creates an extremely weak bond that is prone to sudden and complete failure under minimal stress.

The Cost of Silver Alloys

The primary trade-off for the high performance and versatility of silver alloys is their cost. Silver is an expensive precious metal, and its price directly influences the cost of the filler rod.

For high-volume production of copper-to-copper joints, the cost savings of using a self-fluxing BCuP alloy are substantial.

The Risk of Overheating

Regardless of the alloy used, overheating the copper base metal is a common mistake. Excessive heat can burn away the flux, create heavy oxides that prevent flow, and even weaken the copper itself through excessive grain growth.

Making the Right Choice for Your Goal

Your application's specific requirements will point directly to the correct alloy.

- If your primary focus is cost-effective joining of copper tubes or pipes (HVAC/plumbing): Choose a BCuP phos-copper alloy for its self-fluxing properties and low cost.

- If your primary focus is joining copper to brass fittings or a steel frame: You must use a BAg silver alloy with the correct white brazing flux.

- If your primary focus is maximum joint integrity for a part under high vibration or stress: Select a higher-percentage BAg silver alloy for its superior strength and ductility.

Choosing the right filler metal transforms brazing from a simple joining task into a precise and reliable engineering process.

Summary Table:

| Alloy Type | Best For | Flux Required? | Key Characteristics |

|---|---|---|---|

| Phos-Copper (BCuP) | Copper-to-Copper joints | Self-fluxing | Cost-effective, ideal for plumbing/HVAC |

| Silver Alloys (BAg) | Copper to Brass, Bronze, Steel | Yes, with separate flux | Versatile, strong, ductile, higher cost |

Need expert guidance on selecting the perfect brazing alloy for your specific laboratory or production application? KINTEK specializes in lab equipment and consumables, providing high-quality brazing materials and technical support to ensure your joints are strong, reliable, and cost-effective. Contact our experts today to discuss your project requirements and discover how our solutions can enhance your brazing process!

Visual Guide

Related Products

- Copper Foam

- Thermally Evaporated Tungsten Wire for High Temperature Applications

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Custom PTFE Teflon Parts Manufacturer for Non-Standard Insulator Customization

- High-Purity Titanium Foil and Sheet for Industrial Applications

People Also Ask

- What is the major advantage of sputtering? Unmatched Material Versatility for High-Performance Thin Films

- What is the difference between a lab furnace and a lab oven? Choose the Right Heating Tool for Your Lab

- Why is the industrial process of titanium so expensive? The High Cost of Taming a Reactive Metal

- What are 3 advantages of an electric furnace? Lower Cost, Safer Operation & Universal Availability

- How are the shelves inside an Ultra Freezer designed to maintain temperature uniformity? Ensuring Sample Integrity with Compartmentalized Shelves

- What role does a laboratory shaker play in BPA degradation? Optimize Mass Transfer & Reaction Kinetics

- Is plastic pyrolysis oil better than diesel? A Practical Guide to Waste-to-Energy Fuel

- What are the contaminants in pyrolysis oil? Understanding the Inherent Challenges of Bio-Oil