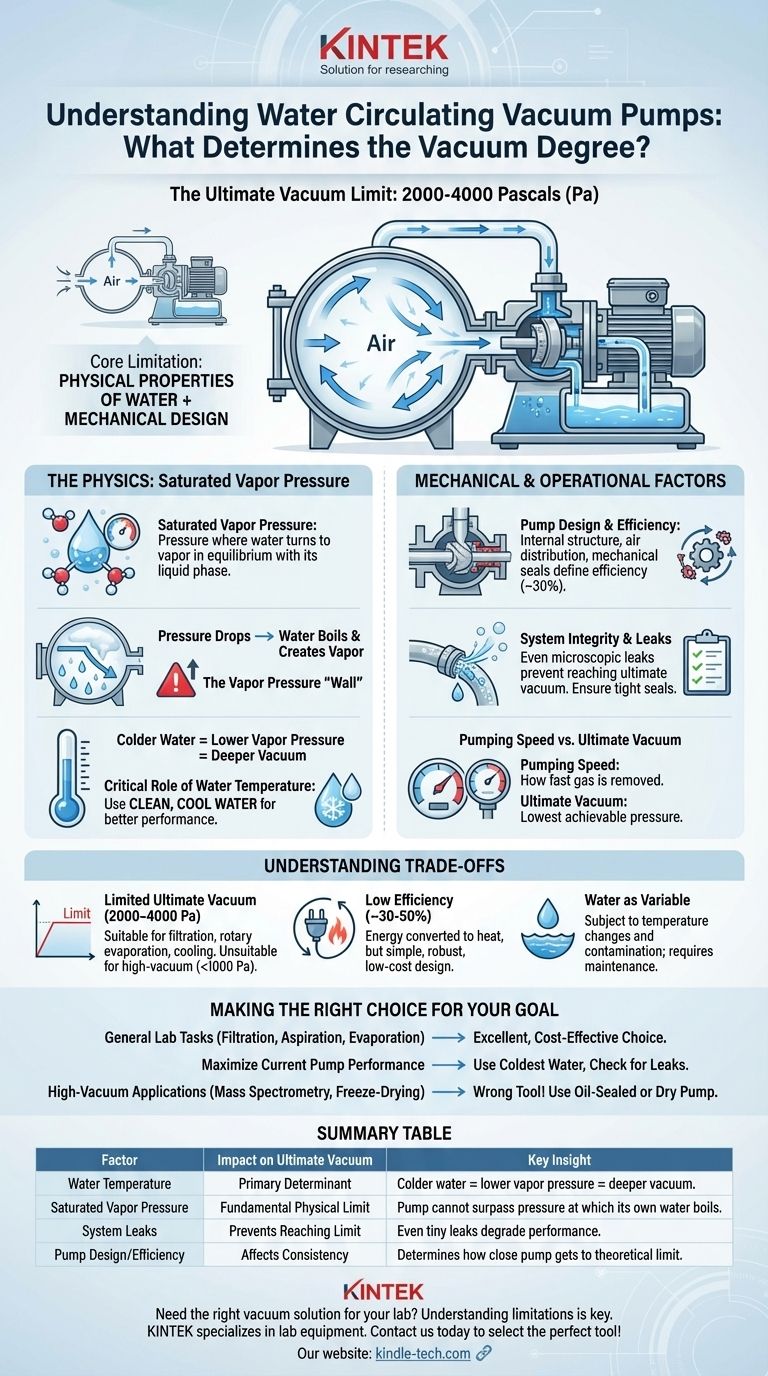

The ultimate vacuum level of a water circulating vacuum pump is determined by two fundamental factors: the physical properties of the water it uses and the pump's own mechanical design. The vacuum is physically limited by the saturated vapor pressure of the water, which dictates the lowest possible pressure the system can reach. For a typical water-based pump, this results in an ultimate vacuum between 2000 and 4000 Pascals (Pa).

A water circulating pump's greatest strength is also its greatest weakness. The very water that creates the vacuum will begin to boil at low pressure, releasing water vapor that prevents the system from achieving a deeper vacuum.

The Physics Behind the Limit: Saturated Vapor Pressure

The core limitation of this pump type is not mechanical, but physical. Understanding this concept is key to operating the pump effectively.

What is Saturated Vapor Pressure?

Saturated vapor pressure is the pressure exerted by a vapor in equilibrium with its liquid phase at a given temperature. In simpler terms, it's the pressure point at which water "wants" to turn into a gas (water vapor).

As the vacuum pump removes air from a sealed system, the pressure inside drops. This process continues until the system's internal pressure becomes equal to the water's saturated vapor pressure.

The Vapor Pressure "Wall"

At this point, the pump hits a "wall." The water circulating within the pump begins to rapidly evaporate or "boil," even at room temperature. This process fills the chamber with water vapor.

The pump is now trying to pump away the very gas its own working fluid is creating. It cannot pull a vacuum lower than the pressure being generated by its own evaporating water, establishing the ultimate vacuum limit.

The Critical Role of Water Temperature

The saturated vapor pressure of water is highly dependent on its temperature. Colder water has a lower vapor pressure.

This is the most critical operational factor you can control. Using colder water will allow the pump to achieve a deeper (lower pressure) vacuum because the water will not start "boiling" until a lower pressure is reached. This is why it is recommended to fill the pump with clean, cool water.

Mechanical and Operational Factors

While physics sets the theoretical limit, mechanical and operational factors determine how close your pump gets to that limit and how efficiently it performs.

Pump Design and Efficiency

The internal structure, including the arrangement of air distribution holes and the tightness of mechanical seals, dictates the pump's overall efficiency. Most water circulating pumps have a relatively low efficiency, often around 30%.

A less efficient pump may struggle to overcome even minor leaks and may not consistently reach the theoretical vacuum limit set by the water temperature.

System Integrity and Leaks

The pump's performance is irrelevant if the equipment it's connected to is leaking. Even a microscopic leak in a hose or connection will allow air to enter the system, preventing the pump from reaching its ultimate vacuum.

Always ensure all nozzles and connection sleeves are tight and perfectly sealed before operation.

Pumping Speed vs. Ultimate Vacuum

It is important to distinguish between the ultimate vacuum (the lowest pressure achievable) and the pumping speed or volume (how fast it removes gas). While factors like motor speed affect how quickly the pump works, they do not change the fundamental physical limit of the vacuum degree.

Understanding the Trade-offs

A water circulating vacuum pump is a valuable tool, but its design comes with inherent compromises.

Limited Ultimate Vacuum

The most significant trade-off is the vacuum level. A limit of 2000-4000 Pa is sufficient for many lab tasks like filtration, rotary evaporation, and providing cooling water. However, it is entirely unsuitable for high-vacuum applications that require pressures below 1000 Pa. For those, an oil-sealed or dry pump is necessary.

Low Efficiency

The typical efficiency of 30-50% means a significant portion of the electrical energy is converted into heat rather than useful work. This is a trade-off for the pump's simple, robust design and low cost.

Water as a Variable

The working fluid—water—is both an advantage and a disadvantage. While inexpensive and safe, its performance is subject to temperature changes, and it can become contaminated over time, requiring periodic replacement to maintain performance.

Making the Right Choice for Your Goal

Use this understanding to match the pump to your specific scientific or experimental objective.

- If your primary focus is general lab filtration, aspiration, or solvent evaporation: This pump is an excellent, cost-effective choice as its vacuum level is perfectly adequate for these tasks.

- If your primary focus is achieving the best possible vacuum with your current pump: Use the coldest water available and meticulously check every hose and connection for leaks to ensure a perfect seal.

- If your primary focus is high-vacuum applications (e.g., mass spectrometry, freeze-drying): This pump is the wrong tool for the job; you must use a technology like an oil-sealed rotary vane pump or a dry scroll pump.

By recognizing that this pump's limits are defined by physics, you can leverage its strengths for the right tasks and avoid frustration when your needs exceed its capabilities.

Summary Table:

| Factor | Impact on Ultimate Vacuum | Key Insight |

|---|---|---|

| Water Temperature | Primary Determinant | Colder water = lower vapor pressure = deeper vacuum. |

| Saturated Vapor Pressure | Fundamental Physical Limit | The pump cannot surpass the pressure at which its own water boils. |

| System Leaks | Prevents Reaching Limit | Even tiny leaks will degrade performance. |

| Pump Design/Efficiency | Affects Consistency | Determines how close the pump gets to its theoretical limit. |

Need the right vacuum solution for your lab? Understanding the limitations of your equipment is the first step to maximizing efficiency. KINTEK specializes in lab equipment and consumables, serving all your laboratory needs. Whether you need a reliable water circulating pump for filtration or a high-vacuum system for more demanding applications, our experts can help you select the perfect tool. Contact us today via our [#ContactForm] to discuss your specific requirements and ensure your lab operates at peak performance!

Visual Guide

Related Products

- Circulating Water Vacuum Pump for Laboratory and Industrial Use

- Laboratory Benchtop Water Circulating Vacuum Pump for Lab Use

- Laboratory Rotary Vane Vacuum Pump for Lab Use

- Oil Free Diaphragm Vacuum Pump for Laboratory and Industrial Use

- Electric Heated Hydraulic Vacuum Heat Press for Lab

People Also Ask

- How can a water bath's temperature be reduced to ambient or lower levels? Expert Cooling Solutions

- What is the necessity of an ultrapure water circulation system? Ensure High-Precision Dynamic Simulation Experiments

- Why is a high-performance cooling circulator necessary in silica membrane desalination? Boost Your Permeate Mass Transfer

- What is the function of a water bath? Achieve Precise, Gentle Heating for Your Lab Samples

- Why is a cold trap system containing isopropanol required for pyrolysis gas? Capture Elusive Volatiles Effectively

- Why is the mechanical agitation provided by a shaking incubator necessary for the enzymatic hydrolysis of biomass?

- What is the necessity of condensing and cooling units in CO2 desorption? Optimize Solvent Recovery & Lab Safety

- How does a circulation reaction system with molecular sieve traps enhance the production of ethylene from biogas?