In essence, a blown film machine is a highly precise piece of industrial equipment that transforms raw plastic pellets into a thin, continuous sheet of plastic film. It accomplishes this through a process of melting, extrusion, and inflation, creating the seamless plastic tubing used for countless applications, from grocery bags to protective agricultural sheeting.

A blown film machine doesn't just melt plastic; it inflates it into a long, continuous bubble. This elegant process of extrusion and air pressure is the fundamental method for creating the vast majority of flexible plastic films used in packaging, agriculture, and construction.

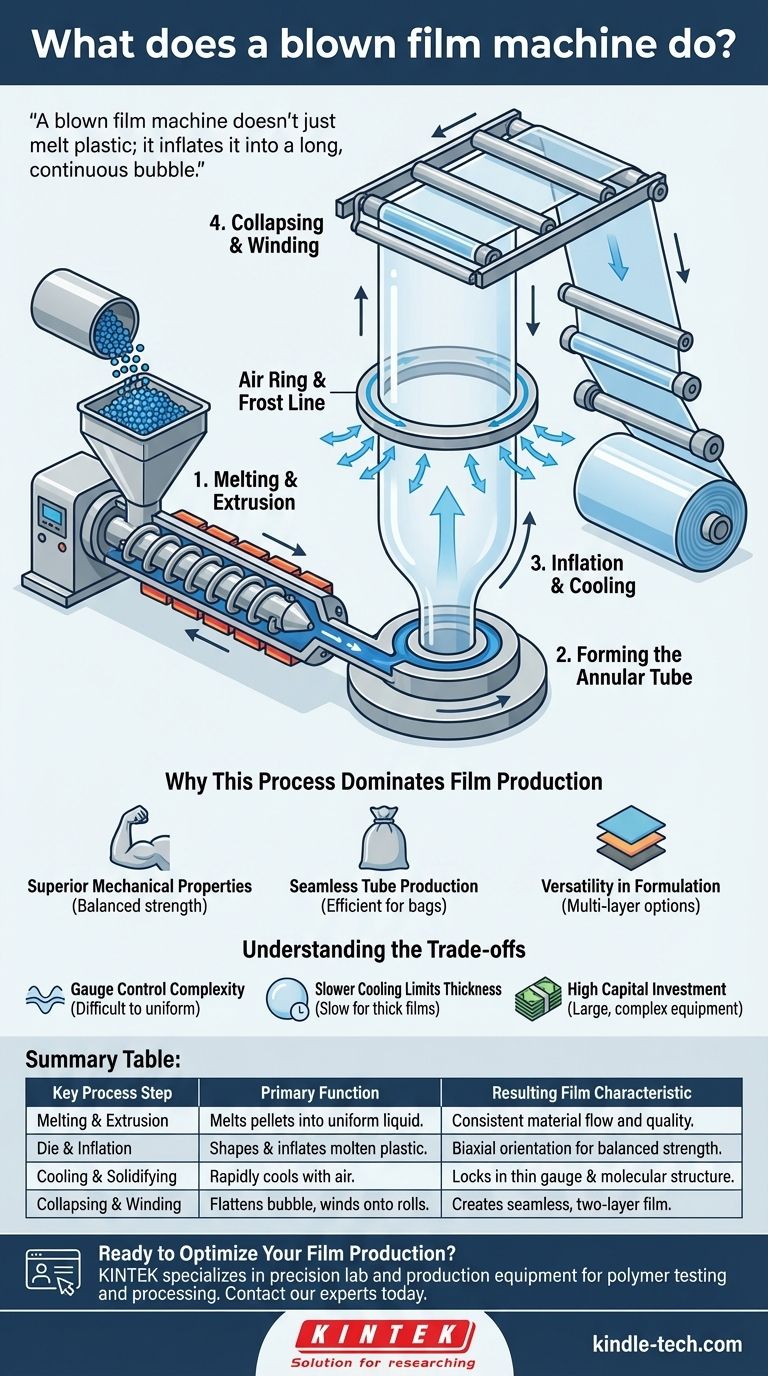

The Core Process: From Pellet to Film Roll

To understand what a blown film machine does, it's best to visualize its operation as a continuous, vertical journey for the plastic material.

Step 1: Melting and Extrusion

The process begins with solid plastic pellets, typically a type of polyethylene (like LDPE, LLDPE, or HDPE). These pellets are fed from a hopper into a long, heated barrel containing a rotating screw. As the screw turns, it conveys the pellets forward, and the combination of heat and pressure melts them into a uniform, molten polymer.

Step 2: Forming the Annular Tube

At the end of the extruder, the molten plastic is forced through a circular die. This die shapes the liquid plastic into a thick-walled tube, often referred to as a parison. The precision of this die is critical for the final film's quality.

Step 3: Inflation and Cooling

This is the "blown" step that defines the process. Air is introduced through the center of the die, inflating the molten tube just like a balloon. This expansion stretches the plastic both radially (in circumference) and axially (in length), creating an extremely thin bubble.

Simultaneously, a high-velocity air ring blows cool air onto the outside of the bubble. This rapidly cools and solidifies the plastic, locking its molecular structure in place at its final, thin dimension. The point where the plastic solidifies is called the "frost line."

Step 4: Collapsing and Winding

The large, stable bubble continues to travel upward, often for several stories in a large production facility, to allow for sufficient cooling. At the top, a collapsing frame gently flattens the bubble into a two-layer flat tube.

This flattened tube is then pulled through a set of rollers, known as nip rollers, which maintain tension and guide the film. Finally, the film is wound onto large rolls. It can be kept as a flattened tube (ideal for bag making) or slit into one or two separate sheets.

Why This Process Dominates Film Production

The blown film method is ubiquitous for several key reasons, making it a cornerstone of the plastics industry.

Superior Mechanical Properties

The biaxial orientation—stretching the material in two directions at once during inflation—imparts balanced and superior mechanical properties. This makes the film strong and resilient against tearing in both the machine direction (MD) and transverse direction (TD).

Seamless Tube Production

The process naturally creates a seamless tube. This is incredibly efficient for manufacturing products like garbage bags, T-shirt bags, and other sacks, as it eliminates the need for side-sealing steps.

Versatility in Formulation

Blown film lines can be configured with multiple extruders (a process called co-extrusion) to create multi-layer films. This allows manufacturers to combine different polymers to achieve specific properties, such as oxygen barriers for food packaging, UV resistance for agricultural films, or puncture resistance for industrial wrap.

Understanding the Trade-offs

While powerful, the blown film process is not without its technical challenges and limitations.

Gauge Control Complexity

Maintaining a perfectly uniform film thickness (gauge) across the entire width of the bubble is difficult. Variations in cooling, airflow, or die temperature can lead to thick or thin spots, requiring sophisticated sensor and control systems to manage.

Slower Cooling Limits Thickness

The process is most efficient for thin films. Producing very thick sheeting on a blown film line is slow because the thick mass of plastic takes much longer to cool and solidify, significantly reducing production speed compared to other methods like cast extrusion.

High Capital Investment

Blown film lines, especially multi-layer co-extrusion systems, are large, complex, and represent a significant capital investment. The machinery and the vertical space required for the tower can be substantial.

How to Apply This to Your Goal

Understanding the fundamentals of the blown film process allows you to make more informed decisions, whether you are sourcing materials or designing a product.

- If your primary focus is packaging design: Recognize that blown film's ability to produce seamless tubes is ideal for creating strong, cost-effective bags and liners.

- If your primary focus is material science: Understand that the biaxial orientation during inflation is the key to the film's balanced tensile strength and puncture resistance.

- If your primary focus is manufacturing efficiency: The key to quality and output lies in precise control over extrusion temperature, air pressure, and cooling rates to maintain a stable bubble and uniform gauge.

By transforming simple pellets into a precisely engineered material, the blown film machine forms the invisible backbone of modern packaging and industry.

Summary Table:

| Key Process Step | Primary Function | Resulting Film Characteristic |

|---|---|---|

| Melting & Extrusion | Melts plastic pellets into a uniform liquid. | Consistent material flow and quality. |

| Die & Inflation | Shapes and inflates the molten plastic into a bubble. | Biaxial orientation for balanced strength. |

| Cooling & Solidifying | Rapidly cools the bubble with air. | Locks in thin gauge and molecular structure. |

| Collapsing & Winding | Flattens the bubble into a tube and winds it onto rolls. | Creates a seamless, two-layer film ready for use. |

Ready to Optimize Your Film Production?

Whether you're developing new packaging, improving material strength, or scaling your manufacturing line, the right equipment is critical. KINTEK specializes in precision lab and production equipment, including solutions for polymer testing and processing that help you perfect your blown film formulations and processes before full-scale production.

Contact our experts today to discuss how our expertise can help you achieve superior film quality, efficiency, and performance.

Visual Guide

Related Products

- Lab Blown Film Extrusion Three Layer Co-Extrusion Film Blowing Machine

- Lab Plastic PVC Calender Stretch Film Casting Machine for Film Testing

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- Single Punch Tablet Press Machine and Mass Production Rotary Tablet Punching Machine for TDP

- Small Injection Molding Machine for Lab Use

People Also Ask

- What is the pyrolysis of natural rubber? A Sustainable Solution for Tire and Rubber Waste

- What are the advantages of a two-high rolling mill? Cost-Effective Durability for Heavy Reduction

- What is the purpose of a vulcanizing machine? Transform Rubber into High-Performance Parts

- What does a rubber mixer do? Transform Raw Ingredients into a High-Performance Compound

- What is the process of pyrolysis of rubber? A Step-by-Step Guide to Converting Waste into Fuel

- How to mix rubber compounds? Choosing Between Open Mill and Internal Mixer

- What is the difference between extrusion coating and extrusion lamination? A Guide to Material Enhancement

- What is the principle of calendering? Enhance Fabric Surface with Heat and Pressure