The primary equipment used in a sieve analysis test is a set of standardized sieves with specific mesh sizes, a mechanical sieve shaker, a high-precision balance or scale, and a collection pan. These components work together to mechanically separate a granular material sample into different size fractions based on particle size.

Sieve analysis is a fundamental materials characterization test that relies on a surprisingly simple set of tools. The key to accurate results lies not in the complexity of the equipment, but in the precision of the sieves and the consistency of the procedure.

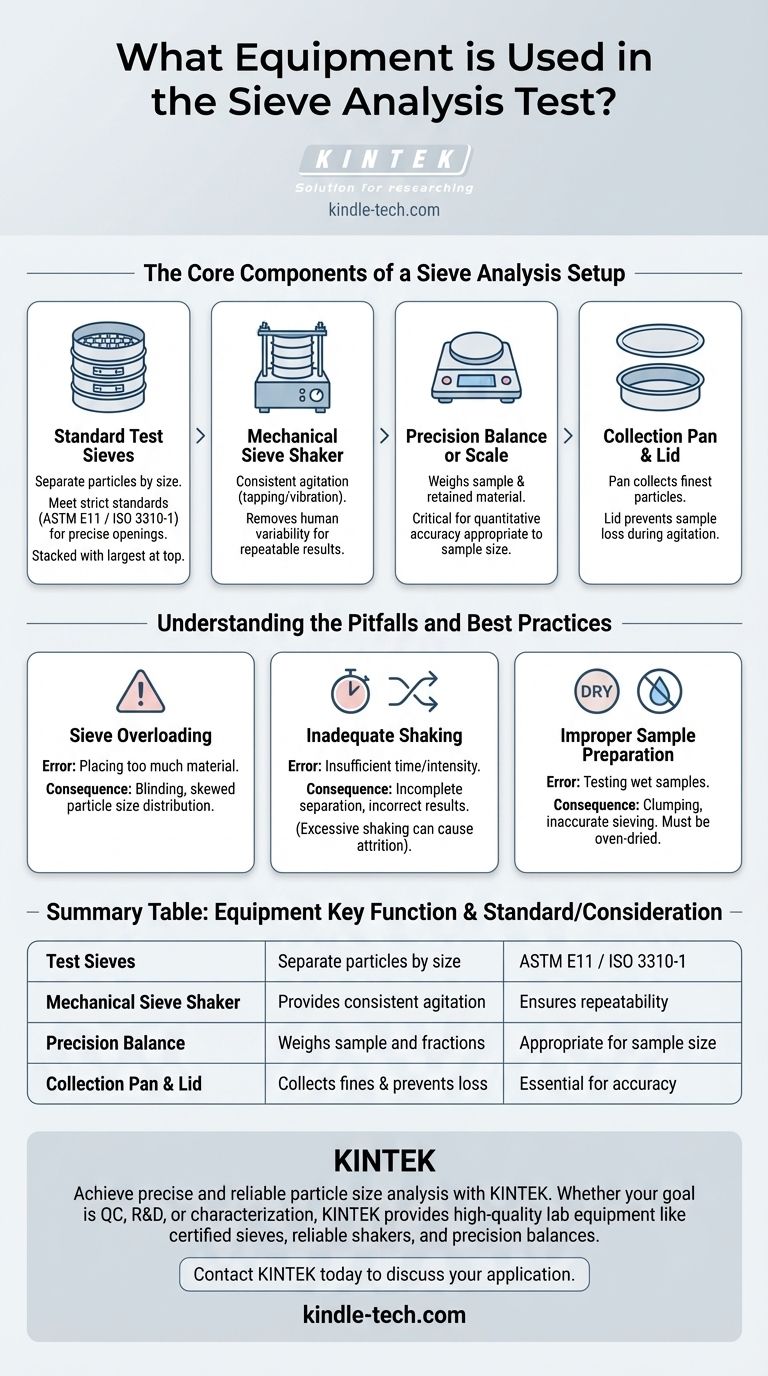

The Core Components of a Sieve Analysis Setup

To properly conduct a sieve analysis, you need a collection of specialized but straightforward tools. Each piece plays a critical role in ensuring the test is accurate and repeatable.

Standard Test Sieves

A test sieve is the heart of the analysis. It consists of a screen with square openings of a precise size, made of woven wire mesh or a perforated plate, mounted in a rigid circular frame.

These sieves are manufactured to meet strict standards, such as ASTM E11 or ISO 3310-1, which dictate the permissible variation in opening sizes.

For a test, sieves are stacked vertically in a "sieve stack," arranged with the largest opening size at the top and progressively smaller openings toward the bottom.

The Mechanical Sieve Shaker

A sieve shaker is a machine that holds the sieve stack and imparts a consistent, standardized motion to it, usually a combination of tapping and vibration.

Its purpose is to remove human variability from the shaking process. This ensures that every sample is subjected to the same level of agitation for the same amount of time, making results repeatable and comparable across different tests.

The Balance or Scale

An accurate balance or scale is critical for the quantitative aspect of the test. It is used to weigh the initial, total sample and then to weigh the amount of material retained on each individual sieve after shaking.

The precision of the balance must be appropriate for the size of the sample being tested to ensure the final calculations are meaningful.

The Collection Pan and Lid

These are simple but essential accessories. The collection pan, sometimes called a receiver, is placed at the very bottom of the sieve stack to collect the finest particles that pass through all the sieves.

A lid is placed on top of the uppermost sieve to prevent any loss of the sample material during the agitation process.

Sieve Brushes

Proper cleaning is essential for accuracy. Specialized sieve brushes with bristles of an appropriate stiffness are used to clean the sieves after each test without damaging the delicate wire mesh.

Understanding the Pitfalls and Best Practices

While the equipment is simple, procedural errors can easily lead to inaccurate results. Understanding these common mistakes is crucial for ensuring the integrity of your data.

Sieve Overloading

The most common error is placing too much material on a sieve. An overloaded sieve does not allow each particle the opportunity to pass through the openings, a phenomenon known as blinding.

This results in an artificially high amount of material being retained on the overloaded sieve and skews the entire particle size distribution.

Inadequate Shaking

Using an insufficient shaking time or intensity will result in incomplete separation. Particles that should have passed through a sieve will be incorrectly counted as being retained on it.

Conversely, excessive shaking, especially with softer materials, can cause particle degradation (attrition), breaking down larger particles and generating more fines, which also skews the results.

Improper Sample Preparation

A sieve analysis should always be performed on a dry sample. Moisture causes fine particles to clump together and stick to larger particles, preventing them from passing through the proper sieve openings.

Samples should typically be oven-dried to a constant weight before testing to eliminate the influence of moisture.

Ensuring Accurate Results for Your Goal

The level of precision required depends entirely on the application of your results.

- If your primary focus is quality control or compliance: Strict adherence to a standard (like ASTM C136) is paramount. Using a calibrated mechanical shaker and certified sieves is non-negotiable for repeatability.

- If your primary focus is research and development: The highest precision is needed. This means using a high-resolution balance, meticulously cleaning sieves between tests, and performing time-of-shaking studies to prevent particle attrition.

- If your primary focus is a general characterization of a material: A manual analysis can suffice, but you must prioritize consistency in your shaking method and duration to produce meaningful, if not certified, data.

By understanding how each piece of equipment contributes to the process, you gain full control over the reliability and accuracy of your particle size analysis.

Summary Table:

| Equipment | Key Function | Key Standard/Consideration |

|---|---|---|

| Test Sieves | Separate particles by size | ASTM E11 / ISO 3310-1 |

| Mechanical Sieve Shaker | Provides consistent agitation | Ensures repeatability |

| Precision Balance | Weighs sample and fractions | Appropriate for sample size |

| Collection Pan & Lid | Collects fines & prevents loss | Essential for accuracy |

Achieve precise and reliable particle size analysis with KINTEK.

Whether your goal is stringent quality control, advanced R&D, or general material characterization, having the right equipment is critical. KINTEK specializes in high-quality lab equipment and consumables, including certified test sieves, reliable mechanical sieve shakers, and high-precision balances designed for accuracy and durability.

Let our experts help you build the perfect sieve analysis setup for your specific laboratory needs. Contact KINTEK today to discuss your application and ensure your results are accurate every time.

Visual Guide

Related Products

- Laboratory Test Sieves and Vibratory Sieve Shaker Machine

- Laboratory Vibratory Sieve Shaker Machine for Dry and Wet Three-Dimensional Sieving

- Laboratory Vibratory Sieve Shaker Machine Slap Vibrating Sieve

- Vibratory Sieve Shaker Machine Dry Three-Dimensional Vibrating Sieve

- Laboratory Vortex Mixer Orbital Shaker Multifunctional Rotation Oscillation Mixer

People Also Ask

- Why is a standardized sieving system necessary for elephant grass research? Ensure Reliable Sample Consistency

- What is the significance of using a fine sieving system for catalyst particles? Optimize Size for Maximum Reactivity

- Why is powder classification using standard sieves essential for SHS reactions? Unlock Superior Nitriding Results

- How do high-precision sieving systems benefit zeolite preparation? Maximize Adsorption for Wastewater Treatment

- What are the disadvantages of sieve machine? Key Limitations in Particle Size Analysis