At its core, a colloid mill is most accurately known as a rotor-stator mill. This name is not just a synonym; it precisely describes the two key components responsible for its operation. The terms are often used interchangeably in industrial contexts to describe a machine that uses high mechanical shear to break down particles and create stable dispersions or emulsions.

The key insight is that understanding the name "rotor-stator mill" is understanding how the machine fundamentally works. It uses a high-speed rotor spinning within a stationary stator to create intense shear forces that homogenize, emulsify, and disperse materials.

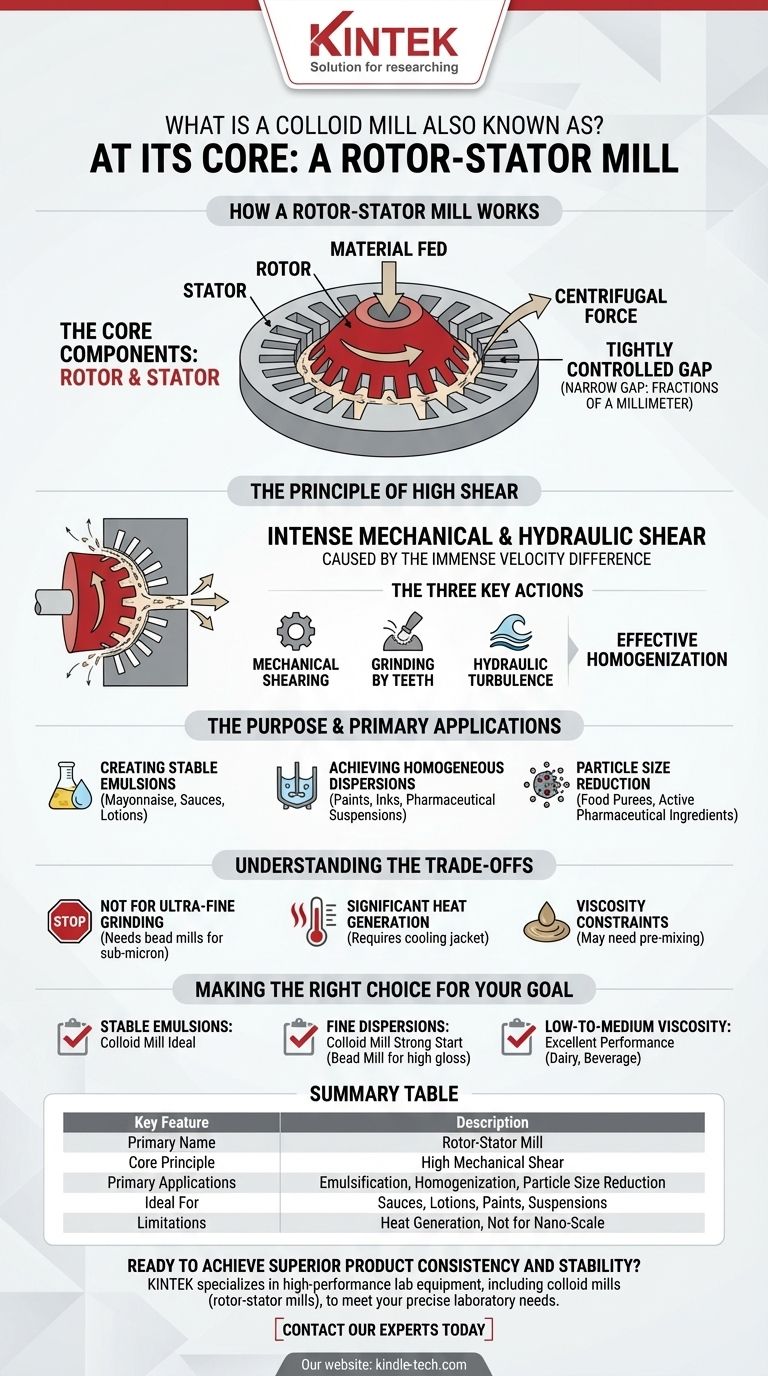

How a Rotor-Stator Mill Works

A colloid mill's effectiveness comes from a simple yet powerful mechanical principle. The design forces material through a tightly controlled gap where it is subjected to immense physical forces.

The Core Components: Rotor and Stator

The rotor is the central, high-speed rotating element. It is typically cone-shaped or disc-shaped with slots or teeth on its surface.

The stator is the stationary component that surrounds the rotor. It has a corresponding pattern of slots or teeth. The gap between the two is extremely small, often adjustable down to fractions of a millimeter.

The Principle of High Shear

Material is fed into the center of the rotor. Centrifugal force throws it outward at high velocity toward the narrow gap between the rotor and stator.

As the fluid is forced through this gap, the immense difference in velocity between the fast-moving rotor and the stationary stator creates intense mechanical and hydraulic shear.

The Three Key Actions

This high-shear environment subjects the material to a combination of forces. It is simultaneously torn apart by mechanical shearing, ground by the teeth, and subjected to high-frequency hydraulic turbulence, leading to effective homogenization.

The Purpose and Primary Applications

A colloid mill is a versatile workhorse used across numerous industries for particle size reduction and fluid mixing. Its function is to create a stable, uniform final product.

Creating Stable Emulsions

One of the most common uses is for emulsification—the process of mixing two liquids that do not normally combine, like oil and water. The mill breaks down droplets to such a small size that they remain suspended, creating products like mayonnaise, sauces, and lotions.

Achieving Homogeneous Dispersions

For products containing solid particles in a liquid base, the mill ensures these particles are broken down and distributed evenly. This prevents settling and creates a consistent texture in products like paints, inks, and pharmaceutical suspensions.

Particle Size Reduction

The intense grinding action effectively reduces the size of solids suspended in a liquid. This is critical for improving the texture, stability, and bioavailability of many products, from food purees to active pharmaceutical ingredients.

Understanding the Trade-offs

While highly effective, a rotor-stator mill is not the solution for every application. Understanding its limitations is key to using it correctly.

Not for Ultra-Fine Grinding

A colloid mill is excellent for reducing particles into the low-micron range. However, for applications requiring sub-micron or nano-scale particles, other technologies like bead mills or high-pressure homogenizers are necessary.

Significant Heat Generation

The high-shear process generates considerable heat due to friction. For heat-sensitive materials, this can be a significant drawback, often requiring the mill to be fitted with a cooling jacket to prevent product degradation.

Viscosity Constraints

While effective for a wide range of viscosities, extremely thick or paste-like materials can be challenging to process. These may require a pre-mixing stage or a more specialized high-viscosity disperser.

Making the Right Choice for Your Goal

Selecting the correct processing equipment depends entirely on your material and desired final product characteristics.

- If your primary focus is creating stable emulsions (sauces, creams, lotions): A colloid mill is an ideal and highly cost-effective technology for this task.

- If your primary focus is producing a fine dispersion (paints, inks): A colloid mill is a strong starting point, but a bead mill may be required for the most demanding high-gloss finishes.

- If your primary focus is homogenizing low-to-medium viscosity fluids: The rotor-stator design provides excellent, efficient performance for applications like dairy processing or beverage production.

Ultimately, knowing that a colloid mill is a rotor-stator mill gives you a clear picture of the mechanical principle that makes it such a versatile and essential piece of industrial equipment.

Summary Table:

| Key Feature | Description |

|---|---|

| Primary Name | Rotor-Stator Mill |

| Core Principle | High mechanical shear between a rotating rotor and stationary stator |

| Primary Applications | Emulsification, Homogenization, Particle Size Reduction |

| Ideal For | Sauces, lotions, paints, pharmaceutical suspensions |

| Limitations | Heat generation; not for nano-scale grinding |

Ready to achieve superior product consistency and stability?

KINTEK specializes in high-performance lab equipment, including colloid mills (rotor-stator mills), designed to meet the precise needs of your laboratory. Whether you are developing new emulsions, creating homogeneous dispersions, or reducing particle size, our solutions deliver reliable, efficient results.

Contact our experts today to find the perfect colloid mill for your application and enhance your lab's capabilities with KINTEK's trusted technology.

Visual Guide

Related Products

- Laboratory Ball Mill Jar Mill with Metal Alloy Grinding Jar and Balls

- Stainless Steel Laboratory Ball Mill for Dry Powder and Liquid with Ceramic Polyurethane Lining

- Disc Cup Vibrating Mill Multi-Platform for Lab

- Laboratory Single Horizontal Jar Mill

- Open Type Two Roll Mixing Mill Machine for Rubber Crusher

People Also Ask

- What is the best material for a ball mill? Choose the Right Grinding Media for Your Application

- What is the primary function of a ball mill in magnesium production? Optimize Pretreatment for Efficiency

- What roles do industrial plant grinders and standard sieves play in Pennisetum alopecuroides pretreatment? Optimize Biomass Efficiency

- Why use ball milling for NMC cathode materials? Achieve Precision Particle Sizing for Composite Cathodes

- Why is the material of the mortar critical for Yttria-stabilized Ceria powder? Ensure Purity with Agate or Zirconia

- What is the primary function of a milling machine in CuCrFeMnNi alloy preparation? Powering Mechanical Alloying

- What are the limitations of ball milling method? Understand the trade-offs of mechanical grinding

- What is the role of a high-energy mixer mill in NVPF preparation? Achieve Atomic-Level Homogeneity for Cathodes