In a vacuum system, a leak is any unintended path that allows gas molecules from the higher-pressure environment outside (typically the atmosphere) to enter the lower-pressure environment inside. This inflow of gas counteracts the work of the vacuum pump, preventing the system from reaching or maintaining its desired level of vacuum.

A vacuum leak is best understood not as a simple hole, but as a constant battle. Your pump works to remove gas molecules, while the leak continuously allows them back in, setting a physical limit on the ultimate pressure your system can achieve.

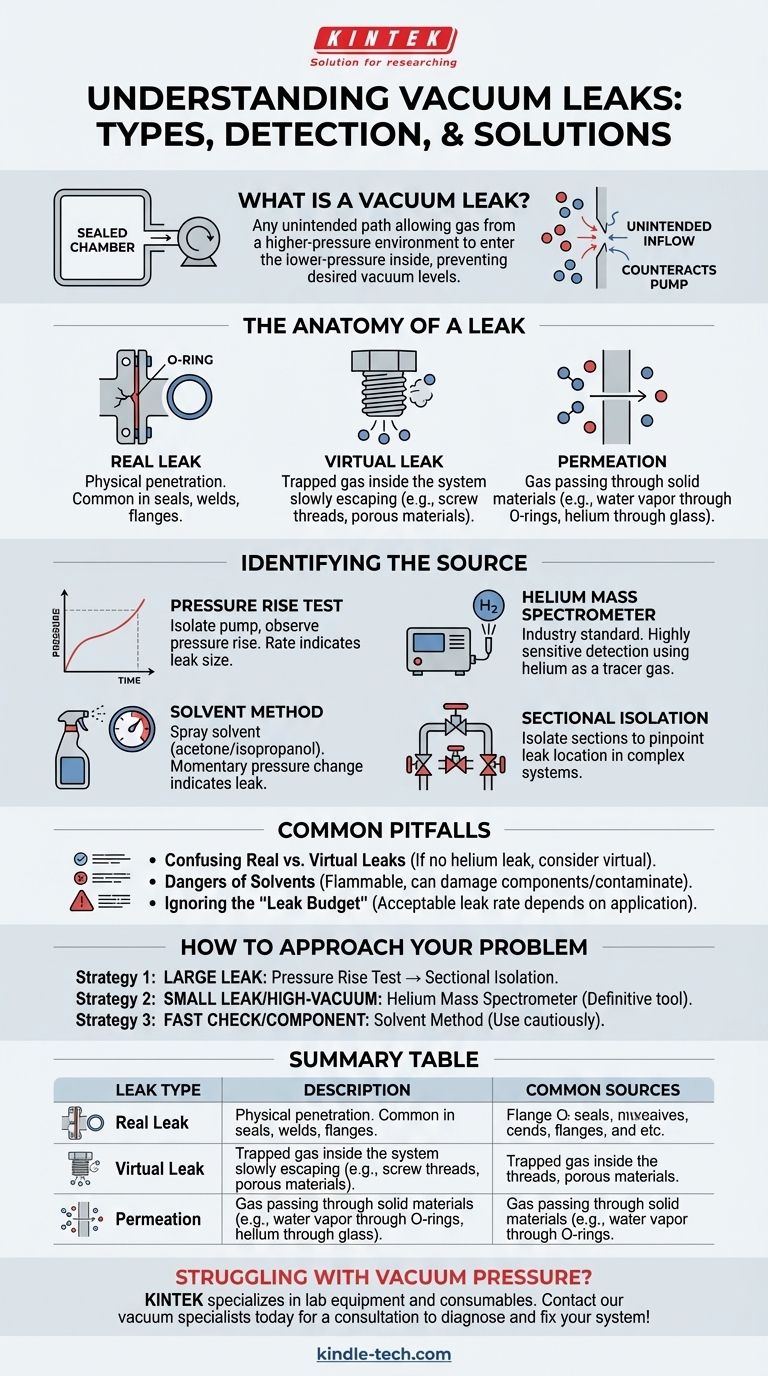

The Anatomy of a Vacuum Leak

Leaks are not always obvious cracks or holes. They can be microscopic, hidden, or even an inherent property of the materials used. Understanding the different types is crucial for effective troubleshooting.

Real Leaks: The Physical Intrusion

A real leak is a physical penetration through the vacuum boundary. This is the most common and intuitive type of leak.

These often occur at connection points like flanges, welds, or feedthroughs where sealing mechanisms have failed. A degraded O-ring, a scratch on a flange surface, or a microscopic crack in a weld are all classic examples.

Virtual Leaks: The Hidden Enemy

A virtual leak is not a physical hole to the outside atmosphere. Instead, it is a volume of trapped gas located inside the vacuum system that slowly escapes into the chamber.

This trapped gas behaves just like a real leak, causing a slow but steady rise in pressure. Common sources include air trapped in the threads of a screw, under a washer, or within porous materials that were not properly baked out.

Permeation: Leaking Through Solids

Permeation is a process where gas molecules pass directly through a solid material that appears impermeable. This is a natural, albeit slow, phenomenon.

For example, elastomers like the rubber in O-rings are susceptible to water vapor permeating through them. In ultra-high vacuum (UHV) systems, even the helium from the atmosphere can slowly permeate through glass viewports.

Identifying the Source of the Leak

Because leaks degrade performance, finding them is a critical diagnostic skill. Methods range from simple pressure observations to highly sensitive electronic instruments.

The Pressure Rise Test

The most fundamental test is to pump the system down to its base pressure, then isolate it from the pump by closing a valve. If the pressure rises rapidly, you have a significant leak. The rate of rise indicates the overall leak size.

Tracer Gas Detection (Helium)

For finding very small leaks, the helium mass spectrometer is the industry standard. The system is connected to the detector, and a fine jet of helium gas is sprayed over suspected leak points on the outside.

If a leak is present, the helium is drawn into the system and immediately detected by the spectrometer, pinpointing the exact location with extreme precision.

The Solvent Method (Acetone/Isopropanol)

A less precise but common field method involves carefully spraying a volatile solvent like acetone or isopropanol alcohol onto a suspected leak area.

When the solvent hits the leak, it is drawn inside. Its presence momentarily changes the gas composition and pressure inside the chamber, causing a noticeable flicker on the vacuum gauge.

Sectional Isolation

For complex systems with many components, you can use blind plates or blank-off flanges to block vacuum tubes in sections. By systematically isolating and testing each section, you can narrow down which part of the system contains the leak.

Common Pitfalls to Avoid

Troubleshooting a leak is often a process of elimination. Being aware of common mistakes can save significant time and resources.

Confusing Real vs. Virtual Leaks

A major pitfall is spending hours searching for a physical hole (a real leak) when the problem is actually outgassing from a poorly designed internal component (a virtual leak). If you cannot find a leak with a helium detector, a virtual leak is a strong possibility.

The Dangers and Limitations of Solvents

While the solvent method is fast, it has risks. Flammable solvents like acetone or ether pose a safety hazard. Furthermore, these chemicals can damage sensitive components like O-rings or contaminate the internal surfaces of the vacuum chamber, creating bigger problems later.

Ignoring the "Leak Budget"

The definition of a "leak" is relative to your goal. A small leak that is completely unnoticeable in a rough vacuum system would be catastrophic for a UHV surface science experiment. Every system has an acceptable total leak rate, known as a leak budget.

How to Approach Your Leak Problem

Your strategy for dealing with a leak should be determined by your system's requirements and the tools available.

- If your primary focus is confirming a large leak in any system: Start with a pressure rise test to confirm the issue and then use sectional isolation to narrow down the general area.

- If your primary focus is finding a very small leak for a high-vacuum application: A helium mass spectrometer leak detector is the only definitive tool for the job.

- If your primary focus is a fast, low-cost check on a specific component (like a flange): The solvent method (preferably with safer isopropanol) can give a quick indication, but use it cautiously and be aware of its limitations.

Mastering your vacuum system begins with understanding that it is a sealed environment, and a leak is anything that violates that seal.

Summary Table:

| Leak Type | Description | Common Sources |

|---|---|---|

| Real Leak | A physical hole or crack allowing gas ingress. | Failed O-rings, flawed welds, scratched flanges. |

| Virtual Leak | Trapped gas inside the system slowly escaping. | Screw threads, under washers, porous materials. |

| Permeation | Gas molecules passing directly through a solid. | O-rings (water vapor), glass viewports (helium). |

Struggling with inconsistent vacuum pressure? A leak could be sabotaging your process reproducibility and data integrity. KINTEK specializes in lab equipment and consumables, serving all your laboratory vacuum needs. Our experts can help you diagnose leak issues and recommend the right equipment or replacement parts to restore your system's performance. Contact our vacuum specialists today for a consultation!

Visual Guide

Related Products

- 304 316 Stainless Steel Vacuum Ball Valve Stop Valve for High Vacuum Systems

- KF/ISO/CF Ultra-High Vacuum Stainless Steel Flange Pipe/Straight Pipe/Tee/Cross

- KF ISO Stainless Steel Vacuum Flange Blind Plate for High Vacuum Systems

- Circulating Water Vacuum Pump for Laboratory and Industrial Use

- Ultra-High Vacuum Flange Aviation Plug Glass Sintered Airtight Circular Connector for KF ISO CF

People Also Ask

- Why use a vacuum furnace? Achieve Ultimate Purity and Precision in Heat Treatment

- What is the function of a vacuum drying oven in catalyst recovery? Maximize Cycle Life and Maintain Active Sites

- What is the contamination in heat treatment? Control Surface Reactions for Superior Component Performance

- Why is a multi-stage aging furnace required for gamma prime phase control in superalloys? Expert Insights.

- Why is it necessary to use a high-vacuum furnace during Active Metal Brazing (AMB)? Ensure Perfect Ceramic-to-Metal Bonds

- What does an annealing furnace do? Relieve Stress and Improve Material Workability

- What is a retort in heat treatment? Achieve Superior Surface Quality and Metallurgical Control

- Why are some furnaces equipped with a second high temperature chamber? For Clean, Compliant Combustion