At its core, a milling jar is a specialized, durable container designed to hold material for grinding, mixing, or pulverizing within a ball mill. It acts as the enclosed chamber where high-energy impacts from grinding media, such as balls or cylinders, systematically break down coarse materials into a fine powder or a homogeneous mixture.

The function of a milling jar goes far beyond simple containment. Its material, size, and the media used within it are critical variables that directly dictate the purity, final particle size, and overall success of your materials processing.

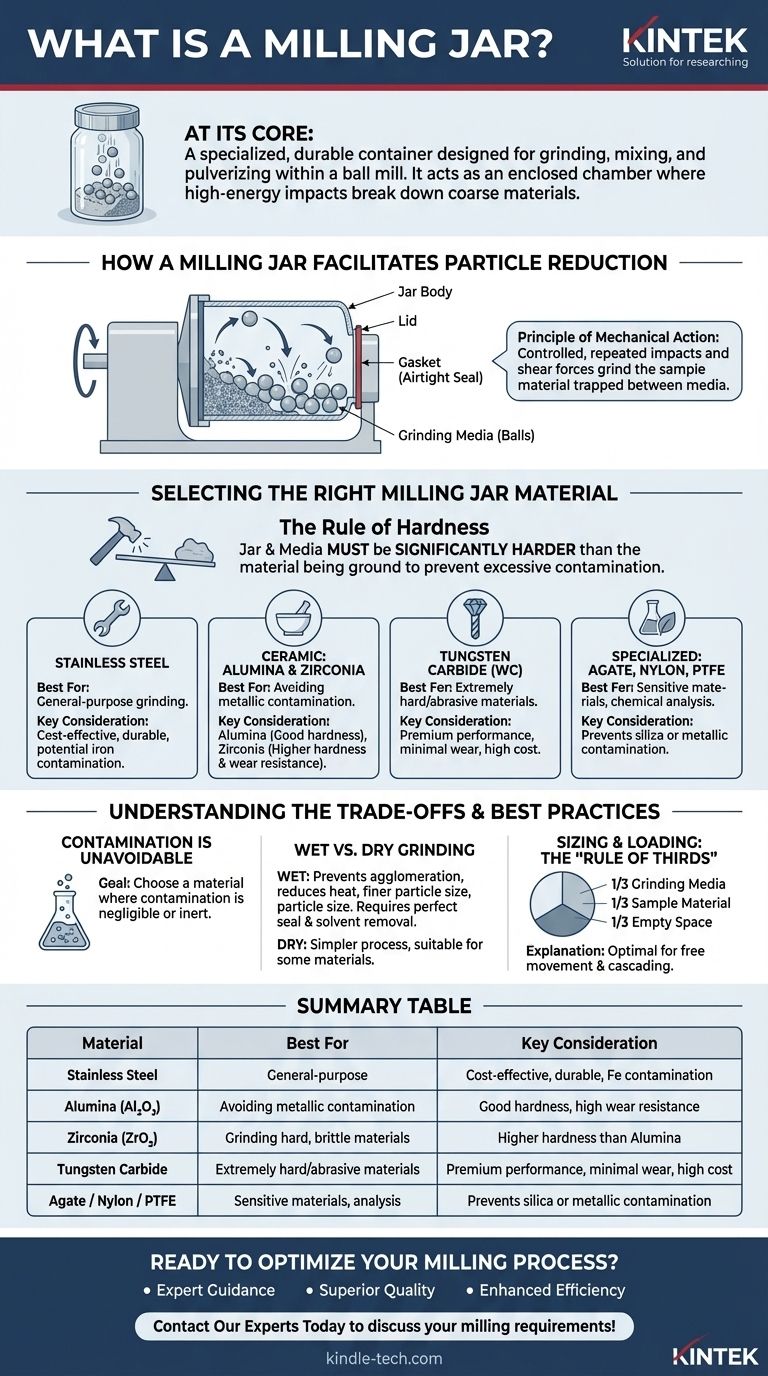

How a Milling Jar Facilitates Particle Reduction

A milling jar is the central component of a ball milling system, a process that relies on mechanical energy to alter a material's physical state. The process is not one of simple crushing but of controlled, repeated impacts.

The Principle of Mechanical Action

The jar is loaded with the sample material and a set of grinding media (balls). It is then sealed and placed into a ball mill, which rotates, shakes, or agitates the jar at high speeds. This motion causes the grinding media to cascade and collide, creating powerful impact and shear forces that grind the sample material trapped between them.

Key Components of the System

A complete milling jar setup consists of the jar body, a matching lid, a gasket to ensure an airtight seal, and the grinding media. The media does the actual work, while the jar and lid contain the energy and prevent contamination.

Selecting the Right Milling Jar Material

The choice of jar material is the single most important decision in the milling process. It directly impacts the potential for sample contamination and the efficiency of the grind.

The Rule of Hardness

The fundamental principle is that the milling jar and grinding media must be significantly harder than the material being ground. If the sample is harder, it will abrade the jar and media, leading to excessive and unacceptable contamination of your sample.

Common Material: Stainless Steel

Stainless steel is a robust, versatile, and cost-effective choice. It is excellent for general-purpose milling of a wide range of materials and is particularly useful when iron contamination is not a concern for the final application.

Ceramic Workhorses: Alumina & Zirconia

Alumina (Al₂O₃) is a very common, high-density ceramic that offers good hardness and high resistance to wear. Zirconia (ZrO₂) is even harder, denser, and more wear-resistant than alumina, making it ideal for grinding very hard, brittle materials with minimal contamination.

The Ultimate Grinder: Tungsten Carbide

For extremely hard or abrasive samples, tungsten carbide (WC) is the premium choice. Its extreme hardness and density provide very high grinding energy, enabling rapid particle size reduction with minimal wear, though it comes at a significantly higher cost.

Specialized Materials for Sensitive Applications

For applications where even minor contamination is critical, specialized materials are used. Agate is used for soft materials to prevent silica or metallic contamination. Nylon or PTFE jars are used for soft, organic samples where metal or ceramic contamination must be avoided entirely.

Understanding the Trade-offs

Selecting a milling jar involves balancing performance, cost, and the specific requirements of your experiment or process. There is no single "best" material, only the most appropriate one for the task.

Contamination is Unavoidable

It is critical to understand that all milling introduces some level of contamination from the jar and media. The goal is to choose a material where this contamination is either negligibly small or chemically inert and irrelevant to your downstream analysis or application.

Wet Grinding vs. Dry Grinding

Grinding can be done dry or wet (by adding a liquid solvent). Wet grinding can prevent material from agglomerating, reduce heat buildup, and often results in a finer and more uniform particle size distribution. However, it requires a jar with a perfect seal and adds a solvent removal step to your process.

Sizing and Loading the Jar Correctly

The efficiency of the grind is highly dependent on how the jar is loaded. An improperly loaded jar will result in a slow, inefficient grind or may not work at all.

The "Rule of Thirds"

A widely accepted guideline for optimal grinding is the "rule of thirds." The jar volume should be filled approximately one-third with grinding media, one-third with the sample material, and the final one-third left as empty space to allow for the free movement and cascading of the media.

Making the Right Choice for Your Application

Your final decision should be guided by your sample's properties and your ultimate goal.

- If your primary focus is general-purpose grinding of soft to medium-hard materials: A stainless steel jar offers the best balance of performance, durability, and cost.

- If your primary focus is avoiding metallic contamination for sensitive analysis: Choose a high-purity ceramic jar like alumina or, for higher performance, zirconia.

- If your primary focus is grinding extremely hard or abrasive materials quickly: Invest in a tungsten carbide jar to minimize wear and contamination.

- If your primary focus is processing soft, sensitive materials for chemical analysis: An agate jar is the ideal choice to ensure the highest sample purity.

Choosing the correct milling jar transforms a routine grinding task into a precise and repeatable scientific process.

Summary Table:

| Milling Jar Material | Best For | Key Consideration |

|---|---|---|

| Stainless Steel | General-purpose grinding | Cost-effective, durable, but may cause iron contamination |

| Alumina (Al₂O₃) | Avoiding metallic contamination | Good hardness, high wear resistance |

| Zirconia (ZrO₂) | Grinding hard, brittle materials | Higher hardness and wear resistance than alumina |

| Tungsten Carbide (WC) | Extremely hard/abrasive materials | Premium performance, minimal wear, high cost |

| Agate / Nylon / PTFE | Sensitive materials, chemical analysis | Prevents silica or metallic contamination |

Ready to Optimize Your Milling Process?

Choosing the right milling jar is critical for achieving the desired particle size and sample purity. KINTEK specializes in high-quality lab equipment and consumables, including a full range of milling jars and grinding media tailored to your laboratory's specific needs.

We provide:

- Expert Guidance: Help you select the perfect jar material for your application.

- Superior Quality: Durable jars that ensure consistent, contaminant-free results.

- Enhanced Efficiency: Achieve faster grinding and more homogeneous mixtures.

Don't let the wrong jar compromise your results. Contact our experts today to discuss your milling requirements and find the ideal solution for your lab!

Visual Guide

Related Products

- Laboratory Ten-Body Horizontal Jar Mill for Lab Use

- Laboratory Grinding Mill Mortar Grinder for Sample Preparation

- Laboratory Hybrid Tissue Grinding Mill

- High Energy Vibratory Laboratory Ball Mill Double Tank Type

- High Energy Vibratory Laboratory Ball Mill Grinding Mill Single Tank Type

People Also Ask

- How do you clean ball mill jars? A Step-by-Step Protocol to Prevent Cross-Contamination

- How does the hardness of grinding jar and ball materials influence mechanochemistry? Optimize Your Impact Energy

- Why is a rotary ball mill with grinding media required for mixing Inconel 625 with carbide powders?

- Why is a zirconia (ZrO2) grinding jar chosen for Na1-xZrxLa1-xCl4 synthesis? Ensure High-Purity Solid Electrolytes

- Why are zirconia (ZrO2) milling jars recommended for sulfide electrolytes? Ensure Purity in Li6PS5Cl Synthesis

- What is the function of grinding jars with transparent windows? Unlock Real-Time In-Situ Mechanochemistry Insights

- What is the function of alumina balls in a horizontal rolling reactor? Enhance Biomass Fractionation Efficiency

- What is the primary role of a drum ball mill in copper-based composite preparation? Achieve Homogeneous Cu-SiC Mixtures