At its core, a sieve is a tool used for separating and measuring the size of particles within a given material. By passing a sample through a screen with openings of a uniform size, it physically sorts the material, retaining larger particles while allowing smaller ones to pass through. This process is fundamental to particle analysis across countless industries.

The true function of a sieve goes beyond simple sorting. It is a precision instrument for particle size analysis, a critical process used to guarantee the quality, consistency, and performance of materials ranging from pharmaceutical powders to construction aggregates.

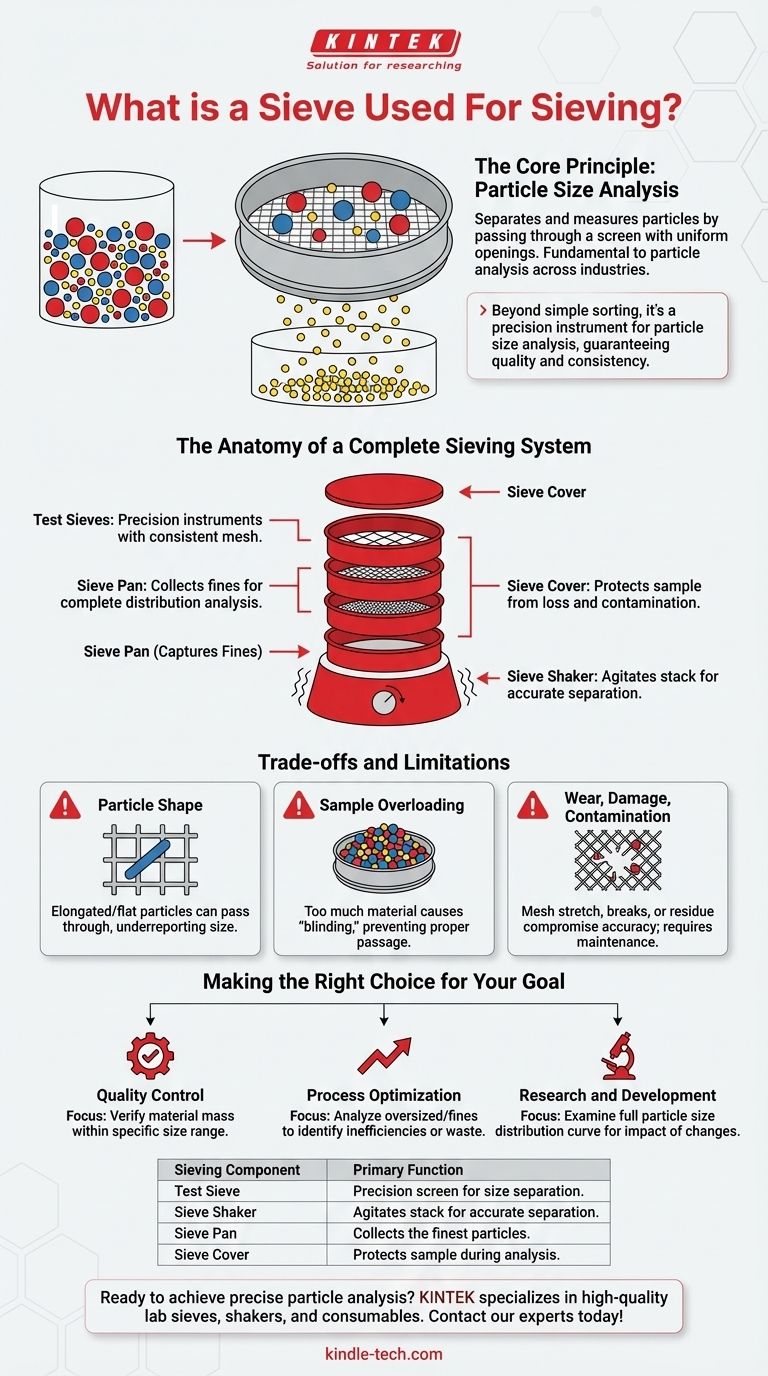

The Core Principle: How Sieving Achieves Particle Analysis

Sieving is a straightforward mechanical process, but its application in a laboratory or industrial setting relies on precision and a systematic approach to generate reliable data.

The Basic Mechanism

A test sieve consists of a screen, typically made of woven wire mesh or a perforated plate, with openings of a specific, uniform size. When a granular material is placed on this screen, particles smaller than the openings fall through, while those that are larger are retained on its surface.

From a Single Sieve to a Sieve Stack

For detailed analysis, multiple sieves are stacked on top of one another. The stack is arranged with the sieve having the largest openings at the top and the one with the smallest openings at the bottom. A solid collection pan is placed at the very bottom of the stack.

The Role of Agitation

This stack of sieves is placed in a sieve shaker. The shaker agitates the stack with a tapping or vibrating motion, ensuring that the material is constantly moving. This gives every particle the opportunity to find its way to the appropriate sieve level based on its size, providing an accurate separation.

The Anatomy of a Complete Sieving System

A professional particle analysis requires more than just a single screen. Each component plays a vital role in ensuring the accuracy and integrity of the results.

Test Sieves: The Heart of the System

These are the precision instruments themselves. Each sieve is manufactured to strict standards to ensure the aperture sizes are accurate and consistent. A full analysis requires a set of sieves with a range of different mesh sizes.

The Sieve Pan: Capturing the "Fines"

Located at the bottom of the sieve stack, the sieve pan is a solid container with no openings. Its crucial function is to collect the smallest particles, known as "fines," that pass through every screen in the stack. Analyzing the mass of these fines is essential for a complete and accurate particle size distribution.

The Sieve Cover: Protecting the Sample

A lid is placed on the top sieve before agitation begins. The cover prevents any loss of the sample material during the vigorous shaking process and also protects it from airborne contamination or changes in moisture, which could skew the results.

Understanding the Trade-offs and Limitations

While powerful, the sieving method has inherent limitations that a professional must consider to correctly interpret the results.

The Problem of Particle Shape

Sieve analysis inherently assumes that all particles are roughly spherical. However, elongated or flat particles may pass through a mesh opening end-on or diagonally, reporting a smaller size than their largest dimension. This can be a significant source of error in certain materials.

Sample Overloading

Placing too much material onto the top sieve is a common mistake. An overloaded sieve prevents particles from having adequate opportunity to pass through the mesh, a phenomenon known as "blinding." This results in an inaccurate reading, with smaller particles being incorrectly retained on upper sieves.

Wear, Damage, and Contamination

Over time, the wire mesh can stretch, sag, or break, compromising the accuracy of the aperture size. Likewise, improper cleaning can leave particles lodged in the mesh, effectively reducing the open area and blocking other particles from passing through. Regular inspection and calibration are critical.

Making the Right Choice for Your Goal

The data from a sieve analysis can be used to answer different questions depending on your objective. Your goal will determine which part of the result you focus on.

- If your primary focus is quality control: You will verify that the majority of your material's mass falls within a specific, narrow size range as defined by your product specifications.

- If your primary focus is process optimization: You will analyze the amount of oversized particles or "fines" to identify inefficiencies or waste in your manufacturing or crushing process.

- If your primary focus is research and development: You will examine the full particle size distribution curve to understand how formulation changes or new processes impact the character of the final material.

Ultimately, sieving transforms a simple physical separation into powerful, quantitative data for controlling processes and guaranteeing product performance.

Summary Table:

| Sieving Component | Primary Function |

|---|---|

| Test Sieve | Precision screen with uniform openings to separate particles by size. |

| Sieve Shaker | Agitates the sieve stack to ensure accurate particle separation. |

| Sieve Pan | Collects the finest particles that pass through all sieves. |

| Sieve Cover | Protects the sample from loss and contamination during analysis. |

Ready to achieve precise particle analysis in your lab? KINTEK specializes in high-quality lab sieves, shakers, and consumables designed for accuracy and durability. Whether you're in pharmaceuticals, construction, or R&D, our equipment helps you guarantee product quality and optimize your processes. Contact our experts today to find the perfect sieving solution for your specific needs!

Visual Guide

Related Products

- Laboratory Test Sieves and Vibratory Sieve Shaker Machine

- Three-dimensional electromagnetic sieving instrument

- Laboratory Vibratory Sieve Shaker Machine for Dry and Wet Three-Dimensional Sieving

- Laboratory Vibratory Sieve Shaker Machine Slap Vibrating Sieve

- Laboratory Multifunctional Small Speed-Adjustable Horizontal Mechanical Shaker for Lab

People Also Ask

- Why use a vibratory sieve shaker for PET powder? Achieve Precise Particle Size Control for Chemical Research

- What is the significance of using a fine sieving system for catalyst particles? Optimize Size for Maximum Reactivity

- Why is a precision vibratory sieving system important for Pt/Pd alloy analysis? Ensure Data Integrity & XRD Accuracy

- Why is a laboratory electromagnetic vibratory sieve shaker used? Optimize Walnut Shell Chemical Pretreatment

- What are the disadvantages of sieve machine? Key Limitations in Particle Size Analysis