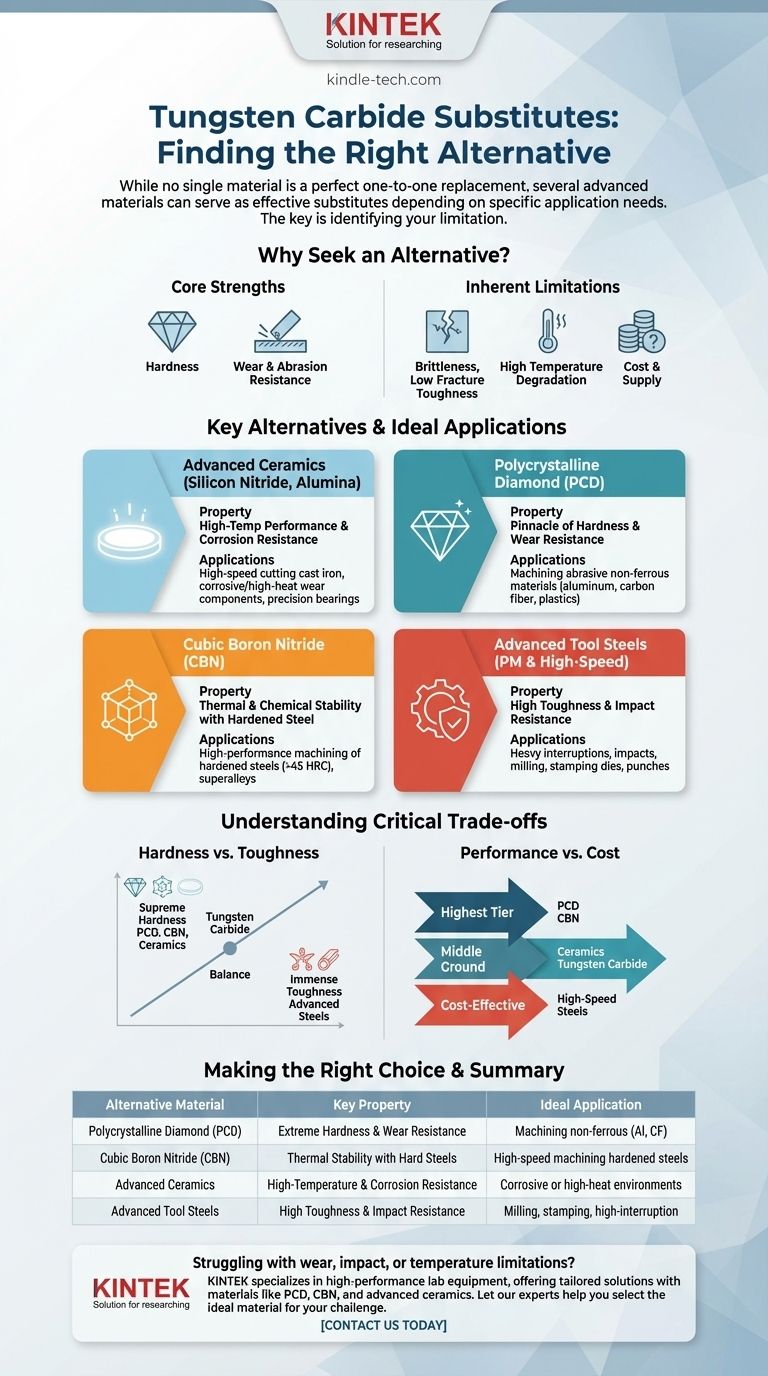

While no single material is a perfect one-to-one replacement, several advanced materials can serve as effective substitutes for tungsten carbide depending on the specific application. The most common alternatives include advanced ceramics (like silicon nitride and alumina), cubic boron nitride (CBN), polycrystalline diamond (PCD), and specialized tool steels, each offering a unique profile of hardness, toughness, and thermal resistance.

The search for a tungsten carbide substitute is not about finding an identical replacement. It's about identifying the specific limitation you face—be it brittleness, cost, or temperature stability—and selecting an alternative material that excels in that particular area.

Why Seek an Alternative to Tungsten Carbide?

To choose the right substitute, you must first understand the specific strengths and weaknesses of tungsten carbide itself. This material is a benchmark for a reason, but it is not the ideal choice for every scenario.

Its Core Strengths

Tungsten carbide is prized for its exceptional hardness, second only to materials like diamond. This hardness translates directly into outstanding wear and abrasion resistance.

It is the go-to material for applications like cutting tools, mining and drilling equipment, and wear-resistant nozzles precisely because it holds a sharp edge and resists physical degradation.

Its Inherent Limitations

The primary driver for seeking alternatives is tungsten carbide's low fracture toughness, or brittleness. It can chip or shatter under sharp impacts or high tensile stress.

Additionally, its performance can degrade at very high temperatures, and its high density makes it heavy, which is a disadvantage in certain high-speed applications. Cost and supply chain volatility can also be significant factors.

Key Alternatives and Their Ideal Applications

Each substitute material occupies a specific niche, excelling where tungsten carbide may fall short. The choice depends entirely on the operational demands.

Advanced Ceramics (Silicon Nitride, Alumina, Zirconia)

Ceramics offer extreme hardness, often coupled with superior high-temperature performance and excellent corrosion resistance.

They are chemically inert and significantly lighter than tungsten carbide. However, they are generally even more brittle.

Best for: High-speed cutting tools for cast iron, wear components in corrosive or high-temperature environments, and precision bearings.

Polycrystalline Diamond (PCD)

PCD is the pinnacle of hardness and wear resistance. It is a synthetic material created by sintering diamond particles together at immense pressure and temperature.

Its primary limitation is its high cost and a thermal reactivity with ferrous metals (iron, steel), which makes it unsuitable for machining steel at high speeds.

Best for: Machining highly abrasive non-ferrous materials like aluminum alloys, carbon fiber composites, and plastics.

Cubic Boron Nitride (CBN)

CBN is the second-hardest known material after diamond. Its key advantage is its thermal and chemical stability when machining iron and hardened steels.

Where PCD would react and break down, CBN remains stable, allowing for extremely high-speed machining of the hardest ferrous metals. Like PCD, its main drawback is high cost.

Best for: High-performance machining of hardened steels (above 45 HRC), superalloys, and other difficult-to-cut ferrous materials.

Advanced Tool Steels

Modern powder metallurgy (PM) and high-speed steels offer a significant advantage in toughness and impact resistance compared to tungsten carbide.

While they cannot match carbide's hardness or wear resistance, they are far more forgiving and resistant to chipping and fracture, often at a lower cost.

Best for: Applications with heavy interruptions or impacts, such as milling operations, stamping dies, and punches where toughness is more critical than ultimate wear resistance.

Understanding the Critical Trade-offs

Choosing a material is always an exercise in balancing competing properties. No single material wins on every metric.

Hardness vs. Toughness

This is the most fundamental trade-off. Materials like PCD, CBN, and ceramics offer supreme hardness but are brittle. As you move toward advanced steels, you sacrifice hardness but gain immense toughness. Tungsten carbide sits in the middle, offering a balance that is effective for many but not all applications.

Performance vs. Cost

PCD and CBN represent the highest tier of performance and cost. Advanced ceramics and tungsten carbide occupy a middle ground, offering excellent performance for their price. High-speed steels provide a tough, reliable, and cost-effective solution when ultimate hardness is not the primary requirement.

Operating Environment

The environment dictates material choice. For extreme heat or corrosive chemicals, ceramics are often the best option. For machining hardened steel at high speeds, CBN is the only viable choice. For high-impact, room-temperature operations, tool steels are superior.

Making the Right Choice for Your Application

Your final decision should be guided by the primary challenge you are trying to solve.

- If your primary focus is extreme wear resistance on non-ferrous materials: Polycrystalline Diamond (PCD) is the superior choice.

- If your primary focus is high-speed machining of hardened steels: Cubic Boron Nitride (CBN) offers the necessary thermal stability and hardness.

- If your primary focus is high-temperature stability or corrosion resistance: Advanced ceramics like silicon nitride or alumina are your best option.

- If your primary focus is impact resistance and toughness: High-speed steels or advanced powder metallurgy (PM) steels provide a more durable solution.

Ultimately, selecting the right material requires a clear definition of your specific operational challenge and performance goals.

Summary Table:

| Alternative Material | Key Property | Ideal Application |

|---|---|---|

| Polycrystalline Diamond (PCD) | Extreme Hardness & Wear Resistance | Machining non-ferrous materials (e.g., aluminum, carbon fiber) |

| Cubic Boron Nitride (CBN) | Thermal Stability with Hard Steels | High-speed machining of hardened steels and superalloys |

| Advanced Ceramics (e.g., Silicon Nitride) | High-Temperature & Corrosion Resistance | Wear components in corrosive or high-heat environments |

| Advanced Tool Steels | High Toughness & Impact Resistance | Milling, stamping dies, and high-interruption operations |

Struggling with wear, impact, or temperature limitations in your lab or production line? KINTEK specializes in high-performance lab equipment and consumables, offering tailored solutions with materials like PCD, CBN, and advanced ceramics to enhance your operational efficiency and tool life. Let our experts help you select the ideal material for your specific challenge—contact us today to discuss your needs and discover how KINTEK can drive your success!

Visual Guide

Related Products

- Professional Cutting Tools for Carbon Paper Cloth Diaphragm Copper Aluminum Foil and More

- Precision Wire Saw Laboratory Cutting Machine with 800mm x 800mm Workbench for Diamond Single Wire Circular Small Cutting

- Glassy Carbon Sheet RVC for Electrochemical Experiments

- Silicon Carbide (SIC) Ceramic Sheet Wear-Resistant Engineering Advanced Fine Ceramics

- Stainless Steel Quick Release Vacuum Chain Three-Section Clamp

People Also Ask

- What physical changes occur during sintering of ceramic powders? Master the Transformation to Dense, Strong Parts

- Is silicon carbide a good electrical insulator? Discover Its Role as a High-Performance Semiconductor

- What are the functions of spring-loaded alumina ceramic rods? Ensure Data Purity in Electrode Test Assemblies

- What are the characteristics of SiC? Unlock High-Temp, Hard, and Chemically Inert Performance

- What are the drawbacks of tungsten carbide? Understanding the Brittleness vs. Hardness Trade-off

- Is ceramic chemically inert? Unlock the Power of Ultimate Chemical Resistance

- What are the roles of sintering additives? Master the Process for Superior Material Performance

- Why is sintering important in ceramic processing? Achieve Dense, High-Performance Ceramic Parts