At its core, an ASTM standard sieve is a highly precise measurement tool designed for separating particles by size. It consists of a woven-wire mesh with openings of a specific, uniform size, mounted in a rigid circular frame. The "ASTM" designation signifies that the sieve has been manufactured and verified to meet the strict specifications of ASTM International, specifically the E11 standard.

The true value of an ASTM standard sieve is not just in the tool itself, but in the system it represents. This standardization ensures that particle size analysis is a repeatable, comparable, and globally understood science, removing ambiguity and ensuring consistent quality control across industries.

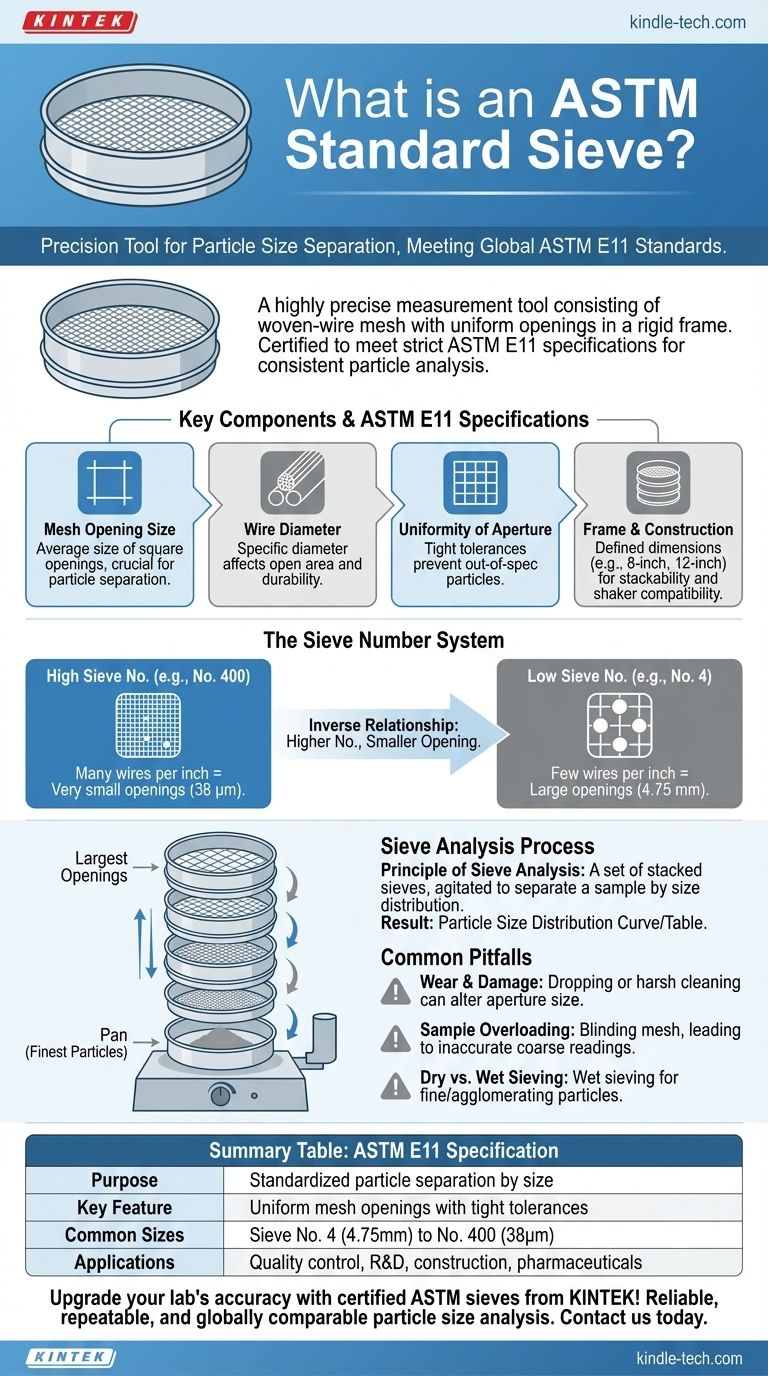

What Makes a Sieve an "ASTM Standard"?

A simple kitchen strainer and an ASTM sieve may look superficially similar, but they are worlds apart in function and purpose. The ASTM designation guarantees a level of precision that is essential for scientific, industrial, and quality control applications.

The Role of ASTM International

ASTM International (formerly the American Society for Testing and Materials) is a global organization that develops and publishes voluntary consensus technical standards.

An ASTM standard like E11, "Standard Specification for Woven Wire Test Sieve Cloth and Test Sieves," ensures that every sieve from any manufacturer that claims compliance will perform identically. This is critical for commerce and research.

Key Specifications in ASTM E11

The E11 standard dictates every critical aspect of the sieve's construction to ensure uniformity and accuracy.

- Mesh Opening Size: This is the most crucial parameter—the average size of the square openings in the wire mesh.

- Wire Diameter: The standard specifies the diameter of the wire used, which affects the percentage of open area and the sieve's durability.

- Uniformity of Aperture: It sets tight tolerances on the variation in opening sizes across the entire surface of the sieve to prevent out-of-spec particles from passing through.

- Frame and Construction: The standard defines the frame's height and diameter (e.g., 8-inch or 12-inch) to ensure sieves are stackable and compatible with mechanical shakers.

The Sieve Number System

ASTM sieves are often identified by a "Sieve No." or mesh number. This number is inversely related to the opening size.

A high sieve number (e.g., No. 400) indicates many wires per inch and therefore very small openings (38 micrometers). A low sieve number (e.g., No. 4) indicates few wires per inch and large openings (4.75 millimeters).

Traceability and Certification

For critical applications, each sieve is marked with a unique serial number. Manufacturers can provide a Certificate of Compliance, which documents that the specific sieve was tested and found to meet the E11 standard. This traceability is essential for regulated environments like pharmaceuticals and aerospace.

How Standard Sieves Work Together

A single sieve can only tell you if particles are larger or smaller than one specific size. The real power comes from using them in a stack to perform a sieve analysis.

The Principle of Sieve Analysis

In a sieve analysis, a set of sieves is arranged in a vertical stack with the largest openings at the top and progressively smaller openings below. A pan at the bottom catches the finest particles.

A pre-weighed sample of the material is placed in the top sieve. The entire stack is then agitated by a mechanical shaker for a set period, allowing particles to find their way down through the openings until they are retained on a sieve too small for them to pass.

Creating a Particle Size Distribution

After shaking, the material retained on each sieve is weighed. This data is used to calculate the weight percentage of particles within each size range.

The result is a particle size distribution, often shown as a table or a curve. This distribution is the key output, providing a detailed "fingerprint" of the material's physical character.

Common Pitfalls and Considerations

Using a standard sieve correctly is just as important as the quality of the sieve itself. Poor technique can easily invalidate results.

Wear and Damage

Sieves are precision instruments. Dropping a sieve, using a sharp tool to clean it, or excessive wear can bend wires and change the aperture size. Regular visual inspection is critical to ensure the mesh is not clogged, warped, or torn.

Sample Overloading

Placing too much material on a sieve is a common mistake. It can "blind" the mesh, preventing particles from having a chance to pass through. This results in an inaccurate reading, showing the material to be coarser than it actually is. ASTM standards provide guidance on maximum sample loads.

Dry vs. Wet Sieving

While dry sieving is most common, very fine materials (typically smaller than 75 µm) or particles that tend to agglomerate may require wet sieving. In this method, water is used to wash the particles through the stack, preventing clumping and clearing the mesh openings.

ASTM vs. ISO Standards

It is important to note that an international standard, ISO 3310-1, also exists. While ASTM and ISO sieve sizes are very similar and often harmonize, they are not always identical. For international trade or collaboration, it is crucial to specify which standard is being used.

Making the Right Choice for Your Goal

Selecting the correct sieves and methods depends entirely on your material and the information you need to extract from it.

- If your primary focus is regulatory compliance or quality control: Always use certified, traceable ASTM or ISO sieves and follow a documented, repeatable procedure for sample size and shaking time.

- If your primary focus is material characterization for R&D: Select a sieve series (like a √2 progression) that provides the necessary resolution to understand the full distribution of your particle sizes.

- If your primary focus is coarse aggregate analysis (e.g., construction): You will use sieves with larger openings, often designated by their size in inches (e.g., 3/4") or millimeters rather than a mesh number.

Using the correct standard sieve transforms particle analysis from a simple sorting exercise into a precise, repeatable scientific measurement.

Summary Table:

| Aspect | ASTM E11 Specification |

|---|---|

| Purpose | Standardized particle separation by size |

| Key Feature | Uniform mesh openings with tight tolerances |

| Common Sizes | Sieve No. 4 (4.75mm) to No. 400 (38µm) |

| Applications | Quality control, R&D, construction, pharmaceuticals |

Upgrade your lab's accuracy with certified ASTM sieves from KINTEK!

KINTEK specializes in high-precision lab equipment and consumables, including a full range of ASTM E11-compliant test sieves. Whether you're in quality control, research, or production, our sieves ensure your particle size analysis is reliable, repeatable, and globally comparable.

Contact us today to discuss your specific needs and ensure your results meet the highest standards.

Visual Guide

Related Products

- Laboratory Test Sieves and Vibratory Sieve Shaker Machine

- Laboratory Vibratory Sieve Shaker Machine for Dry and Wet Three-Dimensional Sieving

- Three-dimensional electromagnetic sieving instrument

- Laboratory Vibratory Sieve Shaker Machine Slap Vibrating Sieve

- Laboratory Multifunctional Small Speed-Adjustable Horizontal Mechanical Shaker for Lab

People Also Ask

- How do high-precision sieving systems benefit zeolite preparation? Maximize Adsorption for Wastewater Treatment

- Why use a vibratory sieve shaker for PET powder? Achieve Precise Particle Size Control for Chemical Research

- What are the disadvantages of sieve machine? Key Limitations in Particle Size Analysis

- What function does a sieving system perform during HPS powder pretreatment? Ensure Uniform Particle Size Distribution

- Why is a precision vibratory sieving system important for Pt/Pd alloy analysis? Ensure Data Integrity & XRD Accuracy