A ball mill is a type of grinder used to reduce the size of solid materials into a fine powder. It operates using a simple and robust principle: a hollow cylinder rotates on its axis, causing grinding media (such as steel or ceramic balls) inside to tumble and crush the material through repeated impact and friction.

The core principle of a ball mill is the transformation of rotational energy into kinetic energy. As the mill's cylinder turns, it lifts the grinding media, which then falls and collides with the material, breaking it down through a combination of impact and attrition.

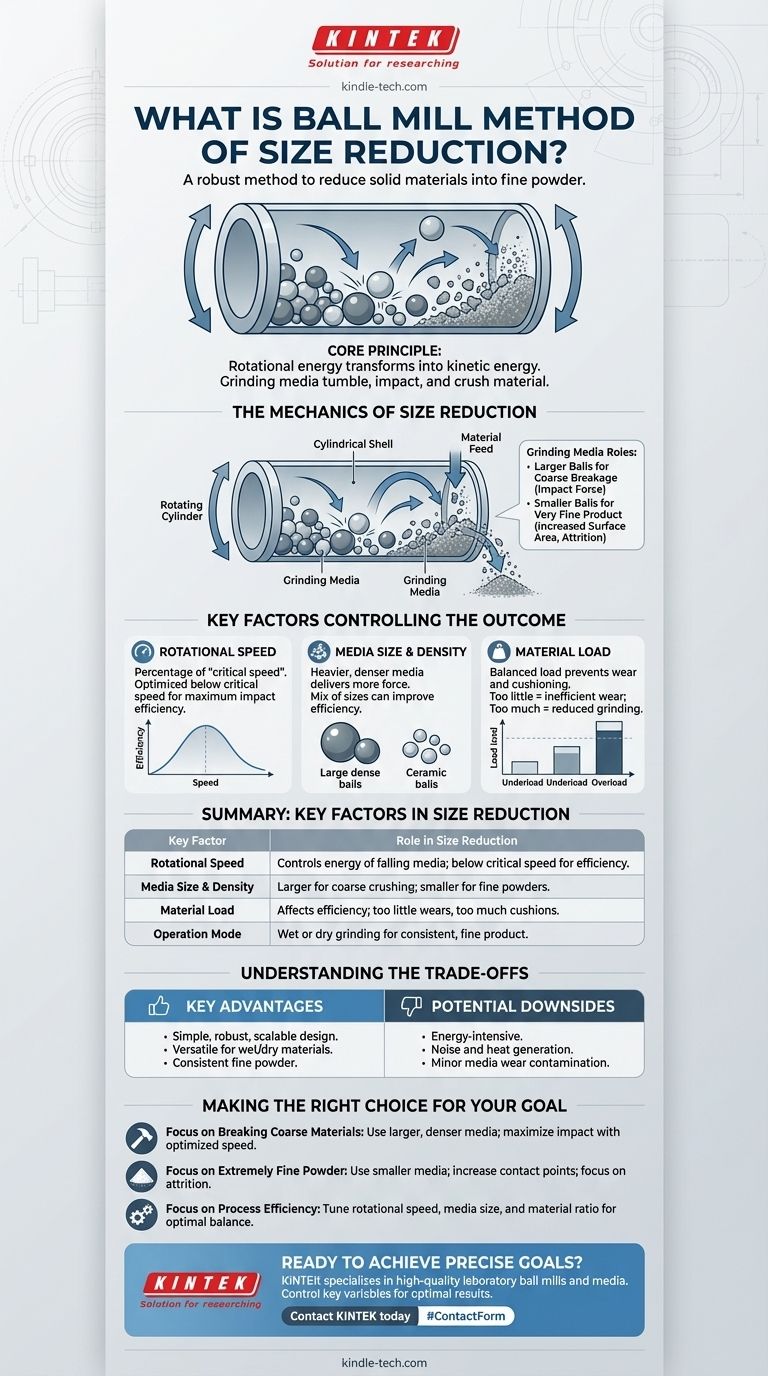

The Mechanics of Size Reduction

A ball mill's effectiveness comes from its carefully controlled, yet chaotic, internal environment. Understanding how these forces work together is key to controlling the final product.

The Cylindrical Shell

The main body of the mill is a rotating cylinder, typically mounted horizontally. This shell is filled with the material to be ground and the grinding media.

The Role of Grinding Media

The "balls" are the heart of the process. They are typically made of high-hardness materials like steel, alumina, or zirconia.

The size of the media is critical. Larger balls are used to break down coarse feed materials, delivering powerful impact forces. Smaller balls are more effective at creating very fine products by filling the gaps and increasing the surface area for grinding.

The Dynamics of Rotation

As the cylinder rotates, the grinding media is lifted up one side before cascading or cataracting back down onto the material. This is where the size reduction occurs.

The speed of this rotation is a crucial parameter. If the speed is too slow, the balls will simply slide down the shell, resulting in little grinding. If it is too fast, centrifugal force will pin the balls to the cylinder wall, preventing them from falling and stopping the grinding process entirely.

Key Factors Controlling the Outcome

To achieve a desired particle size, you must balance several operational variables. The final output is not accidental but a direct result of how the mill is configured and operated.

Rotational Speed

The optimal speed is a specific percentage of the "critical speed"—the theoretical speed at which the media would centrifuge. Operating just below this point maximizes the energy of the falling balls, leading to the most efficient grinding.

Media Size and Density

The choice of grinding media directly impacts the final particle size. Heavier, denser media delivers more force per impact. A mix of ball sizes can sometimes improve efficiency, with large balls handling initial breakage and small balls performing the fine grinding.

Material Load

The amount of material inside the mill is also important. Too little material leads to inefficient energy use and unnecessary wear on the media and mill lining. Too much material can cushion the impact of the balls, reducing grinding effectiveness.

Understanding the Trade-offs

While powerful, the ball mill method is not without its limitations. Being aware of these helps in its proper application.

Key Advantages

The design is simple, robust, and scalable for industrial use. It is also versatile, capable of grinding both wet and dry materials to a very fine, consistent powder.

Potential Downsides

Ball milling can be an energy-intensive process and often generates significant noise. The process can also introduce heat, which may be undesirable for heat-sensitive materials.

Finally, a small amount of wear on the grinding media is inevitable. This can lead to minor contamination of the final product, a critical consideration in high-purity applications like pharmaceuticals or certain ceramics.

Making the Right Choice for Your Goal

The configuration of your ball mill should be directly aligned with your desired outcome. Use these principles as a guide for your specific application.

- If your primary focus is breaking down large, coarse materials: Use larger, denser grinding media and operate at a speed that maximizes impact force through cataracting.

- If your primary focus is producing an extremely fine, uniform powder: Use smaller grinding media to increase the number of contact points and focus on the attrition force generated by cascading.

- If your primary focus is process efficiency: Carefully tune the rotational speed, media size, and material-to-media ratio to find the optimal balance that maximizes size reduction while minimizing energy consumption.

By understanding these fundamental principles, you can effectively control the ball milling process to achieve your particle size reduction goals with precision and reliability.

Summary Table:

| Key Factor | Role in Size Reduction |

|---|---|

| Rotational Speed | Controls the energy of the falling grinding media; must be below critical speed for efficient grinding. |

| Media Size & Density | Larger, denser media for coarse crushing; smaller media for fine powders via increased surface contact. |

| Material Load | Affects grinding efficiency; too little causes wear, too much cushions impact. |

| Operation Mode | Can be used for both wet and dry grinding to achieve a consistent, fine product. |

Ready to achieve your precise particle size reduction goals?

KINTEK specializes in high-quality laboratory ball mills and grinding media designed for reliability and precision. Whether you are processing pharmaceuticals, ceramics, or other materials, our equipment helps you control key variables like rotational speed and media selection for optimal results.

Let our experts help you select the perfect solution for your lab's needs. Contact KINTEL today to discuss your application!

Visual Guide

Related Products

- Stainless Steel Laboratory Ball Mill for Dry Powder and Liquid with Ceramic Polyurethane Lining

- Laboratory Ball Mill Jar Mill with Metal Alloy Grinding Jar and Balls

- Laboratory Single Horizontal Jar Mill

- Laboratory Four-Body Horizontal Jar Mill

- Laboratory Horizontal Planetary Ball Mill Milling Machine

People Also Ask

- How do you increase ball mill efficiency? A Guide to Optimizing Grinding Performance

- What role does a planetary ball mill play in the preparation of CeO2 doped microspheres? Master Material Homogenization

- How do you remove powder from a ball mill? A Step-by-Step Guide to Safe & Efficient Material Recovery

- Why is a ball mill utilized for mechanical mixing in PEO-based electrolytes? Achieve Solvent-Free Purity and Homogeneity

- What function does a ball mill serve in LLZO synthesis? Maximize Your Solid-State Electrolyte Purity

- Which is better rod mill or ball mill? Choose the Right Mill for Your Particle Size Goal

- What is the function of a planetary ball mill in ODS steel preparation? Unlock High-Energy Mechanical Alloying

- What is the purpose of ball milling? A Versatile Tool for Material Synthesis and Modification