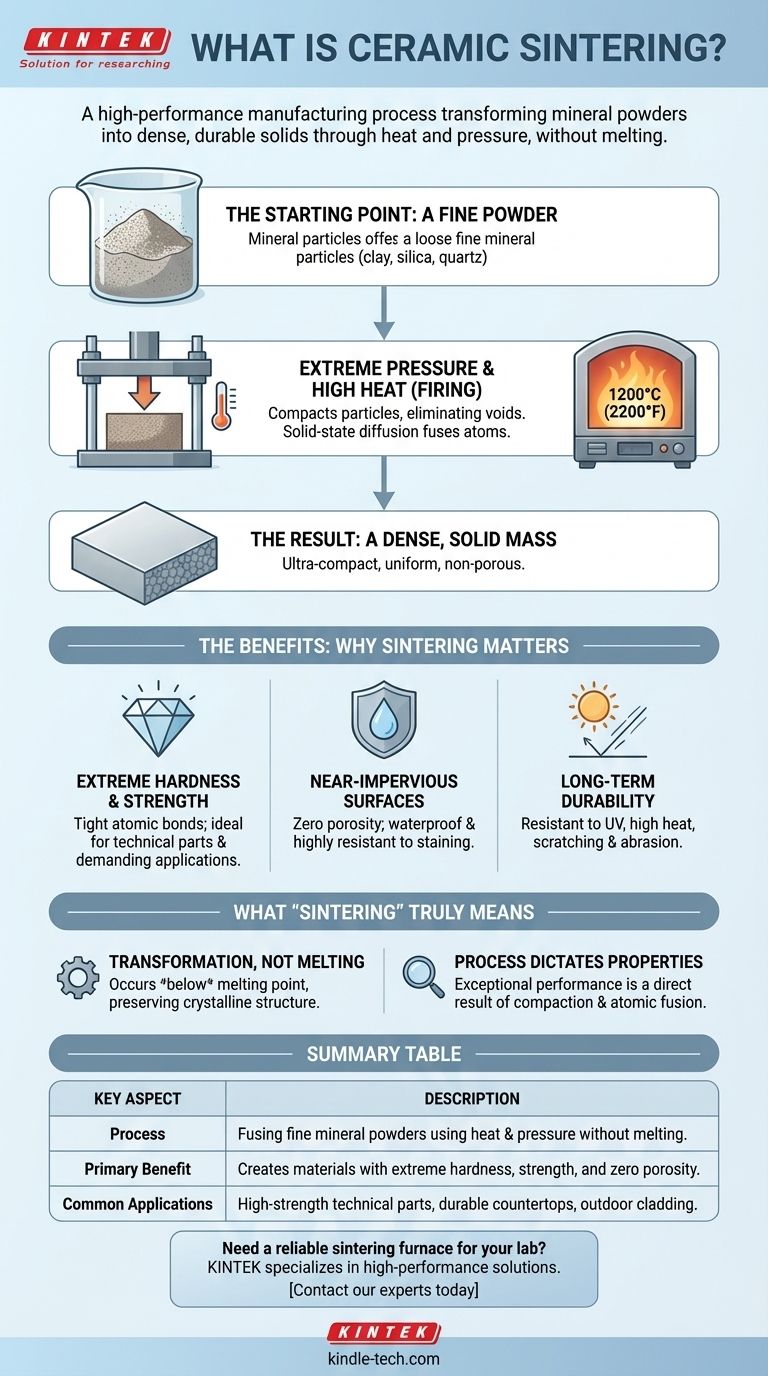

In essence, ceramic sintering is a high-performance manufacturing process that uses intense heat and pressure to compact fine mineral powders into an incredibly dense and durable solid mass. This is achieved without melting the material, instead causing the individual particles to fuse together on an atomic level, radically enhancing the material's final properties.

Sintering is not merely about drying or baking a material; it is a fundamental transformation process. It engineers a new material from a collection of particles, creating a final product with strength and resilience far exceeding its constituent parts.

How Sintering Transforms Raw Materials

The magic of sintering lies in its ability to force separate particles to bond into a single, cohesive unit. This happens through a carefully controlled application of extreme force and thermal energy.

The Starting Point: A Fine Powder

The process begins with natural materials such as clay, feldspar, silica, and quartz. These raw minerals are ground into a fine, consistent powder, which serves as the foundation for the new material.

The Role of Extreme Pressure

This powder is then subjected to immense pressure, sometimes described as exceeding the weight of the Eiffel Tower. This step forces the individual particles into intimate contact, eliminating most of the air and voids between them.

The Function of High Heat

Next, the compacted material is fired in a kiln at temperatures often reaching 1200°C (2200°F). This intense heat provides the energy for atoms on the surfaces of adjacent particles to diffuse and bond together, a process known as solid-state diffusion.

The Result: A Dense, Solid Mass

The final product is a non-porous, ultra-compact slab. The spaces between the original particles have been eliminated, resulting in a material with exceptional density and a uniform internal structure.

The Benefits: Why Sintering Matters

Sintering is employed because it unlocks a level of performance that is impossible to achieve through other means. The properties of a sintered ceramic are a direct result of its ultra-dense, fused structure.

Unlocking Extreme Hardness and Strength

The tight atomic bonds created during sintering result in exceptional hardness and strength. For technical ceramics like zirconia, the process even induces a change in its crystalline structure, transforming it into an extremely hard and dense state used for demanding industrial applications.

Creating Near-Impervious Surfaces

Because a sintered ceramic has virtually zero porosity, it is highly resistant to external elements. This makes it waterproof and exceptionally resistant to staining, as there are no pores for liquids to penetrate.

Ensuring Long-Term Durability

This dense structure also provides superior resistance to scratching, abrasion, and high heat. Sintered surfaces do not fade from UV rays, making them suitable for both high-traffic indoor areas and demanding outdoor applications.

What "Sintering" Truly Means

Understanding the nuances of the process is key to appreciating the final product. The term implies a specific and controlled method of manufacturing.

It's a Transformation, Not Just Melting

A critical distinction is that sintering occurs below the material's melting point. The particles fuse while remaining in a solid state, which preserves a strong crystalline structure. This is fundamentally different from melting and casting, which creates a different internal structure upon cooling.

The Process Dictates the Properties

Terms like "ultra-compact surface" are not just marketing; they are direct descriptions of the outcome. The exceptional performance of sintered stone is a direct consequence of the compaction and atomic fusion that defines the sintering process.

It's a High-Performance Method

While many ceramics are fired in a kiln, sintering represents a more advanced and intensive process. It is used specifically when the goal is to create a material with the highest possible density, hardness, and durability.

How to Apply This Knowledge

Understanding sintering helps you make informed decisions when selecting materials for a project.

- If your primary focus is durability for a countertop or flooring: A sintered ceramic provides unmatched resistance to scratches, stains, and heat compared to many natural stones or other engineered surfaces.

- If your primary focus is an outdoor application: The inherent UV stability and weather resistance of a sintered surface make it a superior choice for cladding or outdoor kitchens.

- If your primary focus is specifying a high-strength technical part: Recognizing that a ceramic is "sintered" confirms it has undergone a process designed to maximize density and mechanical strength.

Ultimately, sintering is the engineering process that transforms humble powders into materials with extraordinary performance.

Summary Table:

| Key Aspect | Description |

|---|---|

| Process | Fusing fine mineral powders using heat and pressure without melting. |

| Primary Benefit | Creates materials with extreme hardness, strength, and zero porosity. |

| Common Applications | High-strength technical parts, durable countertops, outdoor cladding. |

Need a reliable sintering furnace for your lab? KINTEK specializes in high-performance lab equipment, including sintering furnaces designed for precise temperature control and uniform heating. Whether you're developing advanced ceramics or manufacturing durable components, our solutions ensure consistent, high-quality results. Contact our experts today to find the perfect sintering solution for your specific needs!

Visual Guide

Related Products

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1800℃ Muffle Oven Furnace for Laboratory

- 1700℃ Muffle Oven Furnace for Laboratory

People Also Ask

- How does sintering affect ceramics? Mastering the Transformation for Superior Performance

- What are the applications of cubic zirconia? From Jewelry to High-Tech Components

- Does SiC have high thermal conductivity? Unlock Superior Thermal Management for Power Electronics

- What is the main disadvantage of ceramics? The Critical Challenge of Brittleness

- How do you prepare silicon carbide in the laboratory? Master High-Temperature Synthesis Methods

- What are the advantages of silicon carbide? A Super-Material for Extreme Environments

- What catalytic effects do alumina ceramic surfaces have on biomass gasification? Boost Syngas Heating Value

- What is the effect of heating rate on sintering mechanism of alumina nanoparticles? Control Density and Strength