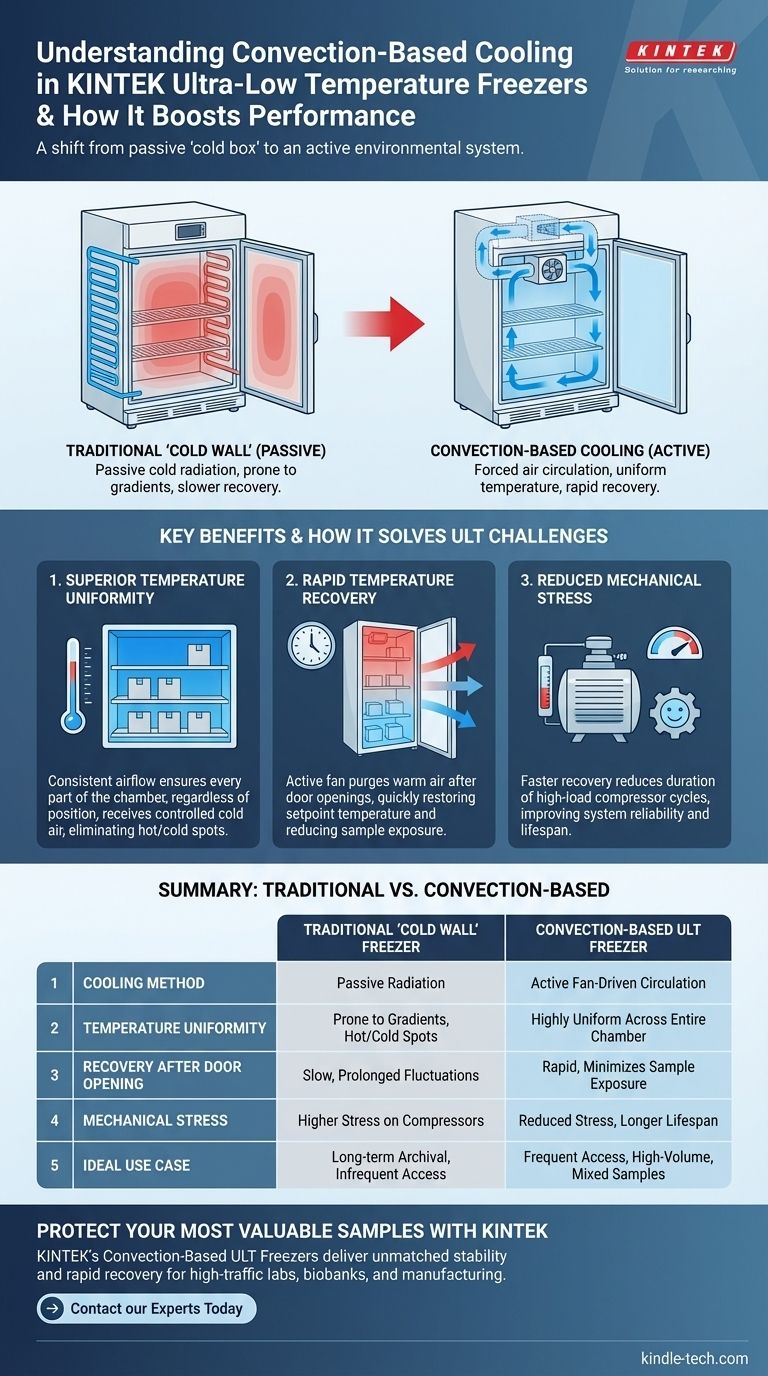

In the world of ultra-low temperature (ULT) storage, convection-based cooling is a technology that actively circulates precisely tempered air throughout the entire freezer chamber. Unlike traditional systems that rely on passive cold radiation from the walls, this forced-air method uses a fan to ensure every part of the chamber receives consistent airflow. This mechanism dramatically improves temperature uniformity, speeds up temperature recovery after door openings, and ultimately reduces mechanical stress on the freezer's components.

The core difference is a shift from a passive "cold box" to an active environmental system. Convection cooling actively manages the internal atmosphere of the freezer, which is the key to maintaining strict temperature stability for sensitive biologicals, especially under real-world conditions of frequent access or high-volume loading.

How Convection Cooling Solves Core ULT Challenges

Standard ULT freezers are essential for preserving materials at temperatures down to -86°C, but maintaining that precise temperature consistently is a significant engineering challenge. Convection technology directly addresses the primary points of failure in temperature stability.

The Problem with Traditional "Cold Wall" Freezers

Many ULT freezers operate using a "cold wall" or direct cooling method. In these systems, refrigerant coils run through the walls of the chamber, passively radiating cold into the interior.

This passive approach can lead to inconsistent temperatures. Areas closer to the coils become colder, while areas in the center or near the door may be several degrees warmer, creating significant temperature gradients that can impact sample integrity.

The Convection Mechanism: Forced Air Circulation

Convection-based systems add a critical component: a fan. This fan drives cold air through ducts and into the chamber, enveloping the stored samples in a continuous, moving stream of tempered air.

This forced circulation actively mixes the air, eliminating the hot and cold spots inherent in passive systems. It ensures the temperature displayed on the screen is the temperature your samples are actually experiencing, regardless of their position on a shelf.

Benefit 1: Superior Temperature Uniformity

The primary advantage of circulating air is unmatched temperature uniformity. By constantly moving air, the system guarantees that samples at the top front of the freezer are held at the same temperature as samples at the bottom back.

This is critical for research and manufacturing applications where sample consistency is paramount. It ensures all materials are preserved under identical conditions, removing a key variable from your process.

Benefit 2: Rapid Temperature Recovery

Every time a freezer door is opened, warm, moist ambient air rushes in, causing a rapid rise in the internal temperature. A convection system excels at recovery.

The fan quickly purges the warm air and replaces it with cold, dry air from the refrigeration system. This brings the chamber back to its setpoint significantly faster than a passive system, minimizing temperature fluctuations and reducing the likelihood of nuisance alarms during daily use.

Benefit 3: Reduced Mechanical Stress

Faster recovery times mean the freezer's compressors don't have to run as long or as hard to combat a temperature breach.

By reducing the duration of these high-load cycles, convection cooling lessens the strain on the cascade refrigeration system. This leads to improved long-term reliability and a longer operational lifespan for the freezer.

Understanding the Trade-offs

No technology is perfect for every scenario. While convection cooling offers significant advantages, it's important to understand its characteristics in context.

Airflow and Sample Protection

The constant movement of air, while excellent for temperature uniformity, has the potential to increase sublimation or desiccation over the very long term if samples are improperly sealed. For this reason, using high-quality cryovials and well-sealed containers is always a best practice.

Comparison to Plate Freezing

Plate freezing involves placing samples (often in bags) in direct contact with extremely cold plates. This method, based on conduction, provides very rapid freezing but is highly specialized.

It lacks the flexibility of a convection freezer, which can accommodate a wide variety of sample containers like boxes, racks, and vials with its modular shelving.

System Complexity

A convection-based freezer contains more moving parts than a simple cold-wall unit, namely the fan and associated ducting. While modern components are highly reliable, this added complexity can introduce additional potential points of failure over the freezer's lifespan compared to a more basic design.

Making the Right Choice for Your Application

The best freezer technology depends entirely on your laboratory's specific workflow, sample value, and operational priorities.

- If your primary focus is bulk storage and frequent access: A convection-based system is superior due to its rapid temperature recovery and uniformity, protecting samples during constant use in a busy lab or manufacturing environment.

- If your primary focus is long-term archival with infrequent access: A traditional cold-wall freezer can be a cost-effective and reliable solution, as the need for rapid recovery is less critical.

- If your primary focus is freezing specific, uniform items like bio-bags: Direct-contact plate freezing offers the fastest heat transfer but lacks the versatility for mixed-use storage.

By understanding the fundamental difference between passive cooling and active air management, you can select a ULT freezer that truly protects your valuable samples.

Summary Table:

| Aspect | Traditional 'Cold Wall' Freezer | Convection-Based ULT Freezer |

|---|---|---|

| Cooling Method | Passive radiation from walls | Active, fan-driven air circulation |

| Temperature Uniformity | Prone to gradients and hot/cold spots | Highly uniform across entire chamber |

| Recovery After Door Opening | Slow, prolonged temperature fluctuations | Rapid, minimizes sample exposure to warm air |

| Mechanical Stress | Higher stress on compressors during recovery | Reduced stress, longer system lifespan |

| Ideal Use Case | Long-term archival with infrequent access | Frequent access, high-volume, mixed sample types |

Protect your most valuable samples with precision and reliability.

At KINTEK, we understand that your laboratory's success depends on the integrity of your biological samples, reagents, and other temperature-sensitive materials. Our range of ultra-low temperature freezers, featuring advanced convection-based cooling technology, is designed to deliver the unmatched temperature stability and rapid recovery your workflow demands.

Whether you're managing a high-traffic research lab, a biobank, or a manufacturing process, KINTEK's ULT freezers provide the peace of mind that comes from knowing your samples are stored under consistently optimal conditions.

Ready to enhance your lab's cold storage capabilities? Contact our experts today to discuss your specific needs and find the perfect ULT solution for your laboratory.

Visual Guide

Related Products

- 158L Precision Vertical Ultra Low Freezer for Laboratory Applications

- 938L Vertical Ultra Low Temperature Freezer for Advanced Laboratory Storage

- 108L Vertical Ultra Low Temperature ULT Freezer

- 408L Advanced Vertical Laboratory Ultra Low Temperature Freezer for Critical Research Material Preservation

- 808L Precision Laboratory Vertical Ultra Low Temperature Freezer

People Also Ask

- What types of materials are commonly stored in ultra low temperature freezers? Preserving Cells, Vaccines & Biomolecules

- How should frost be removed from Ultra-Low Temperature Freezers? Protect Your Samples and Equipment

- How do ultra-low temperature freezers work? Unlocking the Secrets of -86°C Sample Preservation

- How is temperature controlled in ultra low temperature freezers? A Guide to Stable -80°C Storage

- What are the different types of ultra-low temperature freezers available? Choose the Right ULT Freezer for Your Lab