The primary service life advantage of an oil-free vacuum pump stems directly from its design, which is inherently less subject to wear and tear than an oil-sealed equivalent. By eliminating oil from the vacuum generation mechanism, these pumps avoid the component degradation caused by oil breakdown and contamination, resulting in a longer operational lifespan and a reduced need for major servicing.

While oil-free pumps offer a significantly longer potential service life by eliminating oil-related failures, realizing this longevity is not automatic. It depends entirely on performing specific, non-negotiable maintenance tasks that are different, but just as critical, as those for oil-sealed pumps.

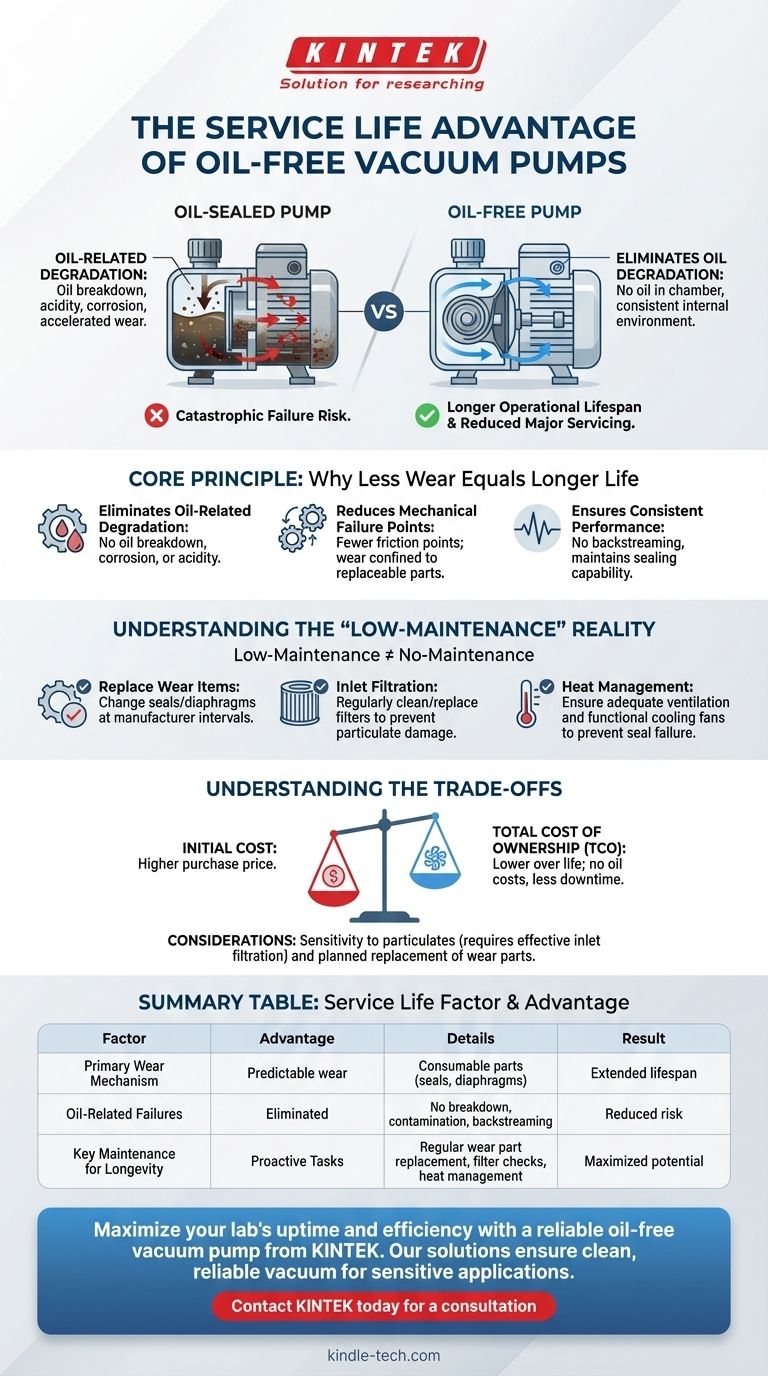

The Core Principle: Why Less Wear Equals Longer Life

The claim of a longer service life for oil-free pumps is rooted in fundamental mechanical and chemical principles. Removing oil from the equation sidesteps several common failure modes that plague traditional pumps.

Eliminating Oil-Related Degradation

In an oil-sealed pump, the oil serves as a sealant and lubricant. Over time and with exposure to heat and process gases, this oil breaks down, losing its viscosity and becoming acidic. This degraded oil can cause corrosion and accelerated wear on internal components, leading to eventual failure.

Oil-free pumps completely bypass this entire failure pathway. There is no oil in the pumping chamber to break down, ensuring a cleaner, more consistent internal environment.

Reducing Mechanical Failure Points

Oil-free designs, such as scroll or diaphragm pumps, often rely on different mechanical principles with fewer high-friction contact points within the vacuum chamber itself. Wear is typically confined to specific, engineered components like tip seals or diaphragms.

These parts are designed as consumables that can be replaced predictably. This contrasts with an oil-sealed pump, where a failure from oil starvation or contamination can cause catastrophic damage to the entire pumping mechanism.

Ensuring Consistent Performance

The absence of oil also prevents "backstreaming," a phenomenon where oil vapor migrates from the pump back into the vacuum chamber. This not only contaminates the process but also signifies a gradual degradation of the pump's sealing capability. An oil-free pump maintains a more stable performance curve over its life.

Understanding the "Low-Maintenance" Reality

The term "low-maintenance" is often associated with oil-free pumps, but it is crucial to distinguish this from "no-maintenance." While they do not require oil changes, they have their own set of maintenance requirements to ensure longevity.

Critical Maintenance Tasks for Longevity

To achieve their maximum potential lifespan, oil-free pumps require diligent, albeit infrequent, attention. Key tasks include replacing wear items like tip seals or diaphragms at manufacturer-recommended intervals.

Regularly cleaning or replacing inlet filters is also essential to prevent particulates from damaging the precise internal mechanisms.

The Critical Role of Heat Management

Overheating is a primary enemy of oil-free pumps. Excessive heat can cause seals to fail prematurely and can warp precision components, leading to a loss of performance or complete failure.

Ensuring adequate ventilation and confirming that cooling fans are operational is arguably the most important routine check for preserving the pump's service life.

Checking and Maintaining Seal Integrity

Seals are critical for isolating the lubricated bearings and motors from the oil-free vacuum chamber. A failed seal can lead to contamination and rapid wear. Periodic inspection is a necessary step to catch potential issues before they cause significant damage.

Understanding the Trade-offs

Choosing a pump technology is never about finding a perfect solution, but about understanding the trade-offs. The extended service life of oil-free pumps comes with its own set of considerations.

Initial Cost vs. Total Cost of Ownership

Oil-free vacuum pumps typically have a higher initial purchase price than their oil-sealed counterparts. The justification for this cost is a lower total cost of ownership (TCO) over the pump's life, driven by reduced maintenance, no oil disposal costs, and longer operational uptime.

Sensitivity to Particulates

While oil in a sealed pump can sometimes trap small amounts of debris, many oil-free designs (especially scroll pumps) are less tolerant of solid particles. This makes effective inlet filtration an absolute requirement, not an option, to protect the investment and ensure a long service life.

Planned Replacement of Wear Parts

The longevity of an oil-free pump is based on the durability of its core housing and motor. However, components like tip seals, diaphragms, and bearings are considered consumables. Achieving a long service life means budgeting for and planning the replacement of these specific parts according to a predictable schedule.

Making the Right Choice for Your Application

Your final decision should be guided by your specific priorities regarding cost, cleanliness, and maintenance workload.

- If your primary focus is a clean vacuum and long-term reliability: An oil-free pump is the superior choice, provided you commit to its specific maintenance schedule for tasks like seal checks and managing heat.

- If your primary focus is the lowest possible initial cost: An oil-sealed pump may be sufficient, but you must factor in the recurring costs and downtime associated with regular oil changes and eventual oil disposal.

- If your primary focus is minimizing hands-on maintenance: Recognize that "low-maintenance" oil-free pumps still demand periodic attention; their reliability is contingent on proactive checks, not neglect.

Ultimately, choosing the right pump technology requires looking beyond the initial price tag to understand the true requirements for a long and reliable service life.

Summary Table:

| Service Life Factor | Oil-Free Pump Advantage |

|---|---|

| Primary Wear Mechanism | Predictable wear on consumable parts (e.g., seals, diaphragms) |

| Oil-Related Failures | Eliminated (no oil breakdown, contamination, or backstreaming) |

| Key Maintenance for Longevity | Regular replacement of wear parts, inlet filter checks, and heat management |

| Result | Significantly extended operational lifespan and reduced total cost of ownership |

Maximize your lab's uptime and efficiency with a reliable oil-free vacuum pump from KINTEK.

KINTEK specializes in high-performance lab equipment and consumables, providing solutions that ensure clean, reliable vacuum for sensitive applications. Our oil-free pumps are designed for long service life, reducing your total cost of ownership and eliminating the hassle of oil changes and disposal.

Let our experts help you select the perfect pump for your needs. Contact KINTEK today for a consultation and discover how our solutions can enhance your laboratory's productivity and reliability.

Visual Guide

Related Products

- Oil Free Diaphragm Vacuum Pump for Laboratory and Industrial Use

- Circulating Water Vacuum Pump for Laboratory and Industrial Use

- Laboratory Rotary Vane Vacuum Pump for Lab Use

- Electric Heated Hydraulic Vacuum Heat Press for Lab

- 30T 40T Split Automatic Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

People Also Ask

- What are some typical applications for oil-free diaphragm vacuum pumps? Ensure Process Purity in Your Lab

- What types of gases can a water circulating vacuum pump handle? Safely Manage Flammable, Condensable & Dirty Gases

- What are the advantages of using oil-free diaphragm vacuum pumps? Achieve Clean, Low-Maintenance Vacuum

- How does the working of oil-free diaphragm vacuum pumps differ from conventional pumps? A Guide to Clean vs. Deep Vacuum

- What factors should be considered when choosing a vacuum pump for laboratory use? Match Your Lab's Needs