High Pressure Reactor

Customizable Laboratory High Temperature High Pressure Reactors for Diverse Scientific Applications

Item Number : KR-6H

Price varies based on specs and customizations

- Max. Working Pressure

- ≤6 MPa

- Temperature Range

- Up to 240°C (Cryogenic use down to -120°C possible)

- Volume

- 25~1000 ml

Shipping:

Contact us to get shipping details Enjoy On-time Dispatch Guarantee.

Why Choose Us

Easy ordering process, quality products, and dedicated support for your business success.

Introduction

This laboratory-scale high-temperature, high-pressure reactor is an integrated system designed for precision, safety, and versatility in demanding research environments. It consists of a robust autoclave vessel housed within an intelligent heating and magnetic stirring control unit, providing a complete solution for hydrothermal synthesis, catalysis studies, and materials processing. Engineered for safety and reliability, the system features a protective explosion-proof enclosure and advanced control features, making it an indispensable tool for scientific innovation.

Key Features

- Integrated Design:The system combines a high-pressure reactor vessel with a dedicated PID-controlled heating and stirring base. A protective housing encloses the reactor during operation, ensuring maximum user safety.

- Durable and Inert Construction: The standard reactor is constructed from high-quality SU304L stainless steel. For experiments involving highly corrosive media, the vessel can be customized with superior materials such as 316L stainless steel, Hastelloy, or Titanium alloys.

- High-Performance Liners: Each reactor is equipped with a removable PTFE liner to ensure chemical inertness and prevent sample contamination. Optional PPL or other advanced polymer liners are available for higher temperature and pressure applications.

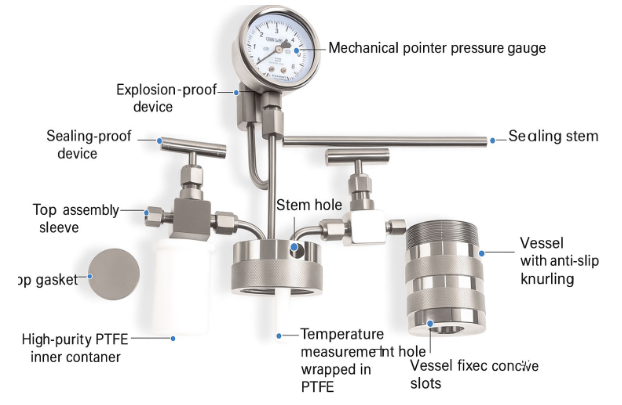

- Precision Instrumentation: The reactor head is fully equipped for process control, featuring a mechanical pressure gauge, dual needle valves for precise gas and liquid handling, and a dedicated port for an internal thermocouple.

- Uncompromised Safety: Safety is paramount. The reactor is protected by a 7 MPa rupture disc to prevent over-pressurization, while the control unit includes automatic heating shut-off for over-temperature conditions and sensor failures.

- Advanced Process Control: The heating base features a clear LCD screen displaying real-time temperature, stirring speed, and time. The advanced PID controller ensures exceptional accuracy (±1°C), while optional upgrades include programmable temperature ramps and 485 communication protocols for data logging and advanced automation.

Detail & Parts

Technical Specifications

Reactor Vessel Specifications

| Feature | Specification |

|---|---|

| Volume (ml) | 25, 50, 100, 150, 200, 250, 300, 500, 1000 |

| Max. Working Pressure | ≤6 MPa |

| Design Pressure | 8 MPa |

| Temperature Range | Up to 240°C (Cryogenic use down to -120°C possible) |

| Body & Lid Material | Standard: SU304L Stainless Steel; Optional: 316L, Hastelloy, Titanium Alloy |

| Liner Material | Standard: PTFE; Optional: PPL, Daikin M111 Imported Fluoropolymer |

| Valves | Standard: 2x 3mm needle valves; Optional: 6mm diameter |

| Safety Device | 7 MPa Rupture Disc |

| Pressure Gauge | Mechanical Gauge (0-6 MPa); other ranges available |

| Options | Acid-resistant PTFE coating for the reactor lid |

Heating & Control Unit Specifications

| Feature | Specification |

|---|---|

| Heating Method | Standard: Electric Heating Mantle; Optional: Modular Block Heater |

| Heating Power | 200 - 1000 W |

| Temperature Control | PID with switchable internal/external sensor modes |

| Temperature Accuracy | ±1°C |

| Stirring Speed Accuracy | ±1 r/min |

| Display | LCD for Temperature, Stirring Speed, and Timer |

| Over-Temp Protection | Audible alarm and auto shut-off for >20°C overshoot |

| Sensor Fault Protection | Audible alarm and auto shut-off if sensor signal is lost for >5 min |

| Timer Function | Auto shut-off after a set time at the target temperature |

| Power Supply | 220V / 50Hz |

| Options | Programmable temperature control with 485 communication for data export |

Applications

This versatile reactor system is ideal for a wide range of advanced applications across multiple scientific disciplines, including:

- Materials Science: Synthesis of nanomaterials, zeolites, metal-organic frameworks (MOFs), and quantum dots.

- Chemistry: High-pressure catalysis, polymerization reactions, and solvothermal synthesis.

- Energy and Environmental: Biomass conversion, supercritical fluid experiments, and corrosion testing.

- Geochemistry: Simulation of geological processes and mineral synthesis.

Value to Our Customers

Our commitment is to provide a solution that perfectly matches your research needs.

- Fully Customizable: We tailor every aspect of the reactor—including volume, materials, pressure ratings, and instrumentation—to your specific experimental parameters.

- Reliability in Extreme Conditions: With high-quality materials and robust safety features, our reactors provide a secure and stable environment for your most critical experiments.

- Enhanced Experimental Repeatability: Precision control over temperature, pressure, and stirring speed ensures consistent conditions, leading to more reliable and repeatable results.

Whether you are developing novel nanomaterials, studying catalytic processes, or require a specialized environment for high-pressure synthesis, our team is ready to engineer a solution tailored to your exact specifications. Discuss your experimental requirements with our specialists to design your ideal reactor system.

Contact us today via our #ContactForm to get started.

Designed for You

KinTek provide deep custom made service and equipment to worldwide customers, our specialized teamwork and rich experienced engineers are capable to undertake the custom tailoring hardware and software equipment requirements, and help our customer to build up the exclusive and personalized equipment and solution!

Would you please drop your ideas to us, our engineers are ready for you now!

Trusted by Industry Leaders

FAQ

What Are Thermal Evaporation Sources?

What Are The Main Types Of Battery Materials?

What Are The Main Types Of Thermal Evaporation Sources?

What Are The Applications Of Battery Materials?

How Do Thermal Evaporation Sources Work?

How Do Battery Materials Enhance Battery Performance?

What Are The Advantages Of Using Thermal Evaporation Sources?

What Is The Role Of Polyethylene Separators In Lithium-ion Batteries?

What Applications Are Thermal Evaporation Sources Used For?

Why Are Conductive Carbon Cloths/papers/felts Important In Battery Applications?

What Are The Advantages Of Using Aluminum-plastic Flexible Packaging Films For Lithium Batteries?

How Does The Lithium Cobaltate Material Contribute To Battery Performance?

What Is The Function Of Battery Internal Resistance Testers?

Why Are Nickel-aluminum Tabs Important In Battery Manufacturing?

4.8 / 5

Incredible quality and precision! These reactors have transformed our lab's efficiency. Worth every penny!

4.9 / 5

Fast delivery and top-notch performance. The customization options are a game-changer for our research.

4.7 / 5

Durable and reliable under extreme conditions. Perfect for high-pressure experiments. Highly recommend!

4.9 / 5

Cutting-edge technology at its finest. Our lab's productivity has skyrocketed since we got these reactors.

4.8 / 5

Exceptional value for money. The build quality is outstanding, and they handle high temps flawlessly.

4.7 / 5

Superb craftsmanship and easy to use. These reactors have exceeded all our expectations.

4.9 / 5

A must-have for any serious lab. The performance is unmatched, and the delivery was lightning-fast.

4.8 / 5

Innovative design and robust construction. Perfect for diverse scientific applications. Love it!

4.7 / 5

Highly customizable and built to last. These reactors are a fantastic investment for any lab.

4.9 / 5

Top-tier performance and durability. The reactors handle extreme conditions with ease. Impressive!

4.8 / 5

Precision engineering at its best. These reactors have significantly boosted our research capabilities.

4.7 / 5

Reliable and efficient. The customization options make these reactors ideal for any lab setup.

REQUEST A QUOTE

Our professional team will reply to you within one business day. Please feel free to contact us!

Related Products

Portable High Pressure Laboratory Autoclave Steam Sterilizer for Lab Use

Portable autoclave sterilization pressure is a device that uses pressure saturated steam to quickly and effectively sterilize items.

Hydraulic Diaphragm Lab Filter Press for Laboratory Filtration

Hydraulic diaphragm lab press filter is one type lab scale filter press, it takes small footprint, and higher pressing power.

Laboratory Manual Hydraulic Pellet Press for Lab Use

Efficient sample preparation with small footprint Manual Lab Hydraulic Press. Ideal for material researching labs, pharmacy, catalytic reaction, and ceramics.

Automatic High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

The High Temperature Hot Press is a machine specifically designed for pressing, sintering and processing materials in a high temperature environment. It is capable of operating in the range of hundreds of degrees Celsius to thousands of degrees Celsius for a variety of high temperature process requirements.

Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

The High Temperature Hot Press is a machine specifically designed for pressing, sintering and processing materials in a high temperature environment. It is capable of operating in the range of hundreds of degrees Celsius to thousands of degrees Celsius for a variety of high temperature process requirements.

Customizable High Pressure Reactors for Advanced Scientific and Industrial Applications

This laboratory-scale high-pressure reactor is a high-performance autoclave engineered for precision and safety in demanding research and development environments.

Manual Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

The Manual Heat Press is a versatile piece of equipment suitable for a variety of applications, operated by a manual hydraulic system that applies controlled pressure and heat to the material placed on the piston.

Laboratory Manual Hydraulic Pellet Press for Lab Use

Efficient Manure Lab Hydraulic Press with Safety Cover for sample preparation in material research, pharmacy, and electronic industries. Available in 15T to 60T.

Warm Isostatic Press WIP Workstation 300Mpa for High Pressure Applications

Discover Warm Isostatic Pressing (WIP) - A cutting-edge technology that enables uniform pressure to shape and press powdered products at a precise temperature. Ideal for complex parts and components in manufacturing.

Warm Isostatic Press for Solid State Battery Research

Discover the advanced Warm Isostatic Press (WIP) for semiconductor lamination. Ideal for MLCC, hybrid chips, and medical electronics. Enhance strength and stability with precision.

Molybdenum Disilicide (MoSi2) Thermal Elements Electric Furnace Heating Element

Discover the power of Molybdenum Disilicide (MoSi2) Heating Element for high-temperature resistance. Unique oxidation resistance with stable resistance value. Learn more about its benefits now!

Mini SS High Pressure Autoclave Reactor for Laboratory Use

Mini SS High Pressure Reactor - Ideal for medicine, chemical, and scientific research industries. Programmed heating temp and stirring speed, up to 22Mpa pressure.

Manual button battery sealing machine

The manual button battery sealing machine is a high-precision packaging device designed specifically for small button batteries (such as CR2032, LR44 and other models). It is suitable for laboratory research and development, small batch production and teaching demonstrations.

UV Lamp Trolley for Laboratory and Hospital Use

The UV lamp trolley is made of cold-rolled plate sprayed with plastic, and adopts a double-lamp structure; it is movable, foldable, and equipped with universal wheels, which is very convenient to use.

Cylindrical Resonator MPCVD Machine System Reactor for Microwave Plasma Chemical Vapor Deposition and Lab Diamond Growth

Learn about Cylindrical Resonator MPCVD Machine, the microwave plasma chemical vapor deposition method used for growing diamond gemstones and films in the jewelry and semi-conductor industries. Discover its cost-effective advantages over traditional HPHT methods.

Electric Heated Hydraulic Vacuum Heat Press for Lab

The Electric Vacuum Heat Press is a specialized heat press equipment that operates in a vacuum environment, utilizing advanced infrared heating and precise temperature control for high quality, rugged and reliable performance.

Custom PTFE Teflon Parts Manufacturer for Gaskets and More

Gaskets are materials placed between two flat surfaces to enhance the seal. To prevent fluid leakage, sealing elements are arranged between static sealing surfaces.

Cold Isostatic Pressing Machine CIP for Small Workpiece Production 400Mpa

Produce uniformly high-density materials with our Cold Isostatic Press. Ideal for compacting small workpieces in production settings. Widely used in powder metallurgy, ceramics, and biopharmaceutical fields for high-pressure sterilization and protein activation.

Square Lab Press Mold for Laboratory Applications

Create uniform samples easily with Square Lab Press Mold - available in various sizes. Ideal for battery, cement, ceramics, and more. Custom sizes available.

Custom PTFE Teflon Parts Manufacturer for Culture Dish and Evaporation Dish

The PTFE culture dish evaporating dish is a versatile laboratory tool known for its chemical resistance and high-temperature stability. PTFE, a fluoropolymer, offers exceptional non-stick properties and durability, making it ideal for various applications in research and industry, including filtration, pyrolysis, and membrane technology.

Related Articles

The Architecture of Precision: Mastering Electrolytic Cell Maintenance

Reliable data starts with disciplined maintenance. Discover the psychological and technical approach to preserving electrolytic cells for peak performance.

The Invisible Geography of Heat: Why "Max Temperature" is a Trap

In thermal processing, maximum temperature is often a vanity metric. Discover why the "Uniform Heated Zone" is the true architect of repeatability.

The Architecture of Certainty: Why Three Electrodes Are Better Than Two

Discover why the three-electrode system is the standard for electrochemical precision, separating current flow from voltage measurement for true analytical clarity.