At its core, ball milling is a mechanical process designed to grind materials into fine powders. It works by placing the material inside a rotating jar along with grinding media, typically hard balls, which repeatedly impact the material and break it apart. This method leverages raw mechanical energy to induce significant structural and chemical changes.

The fundamental principle of ball milling is not just about size reduction; it's about using intense, localized mechanical force to alter a material's physical structure, for better or for worse.

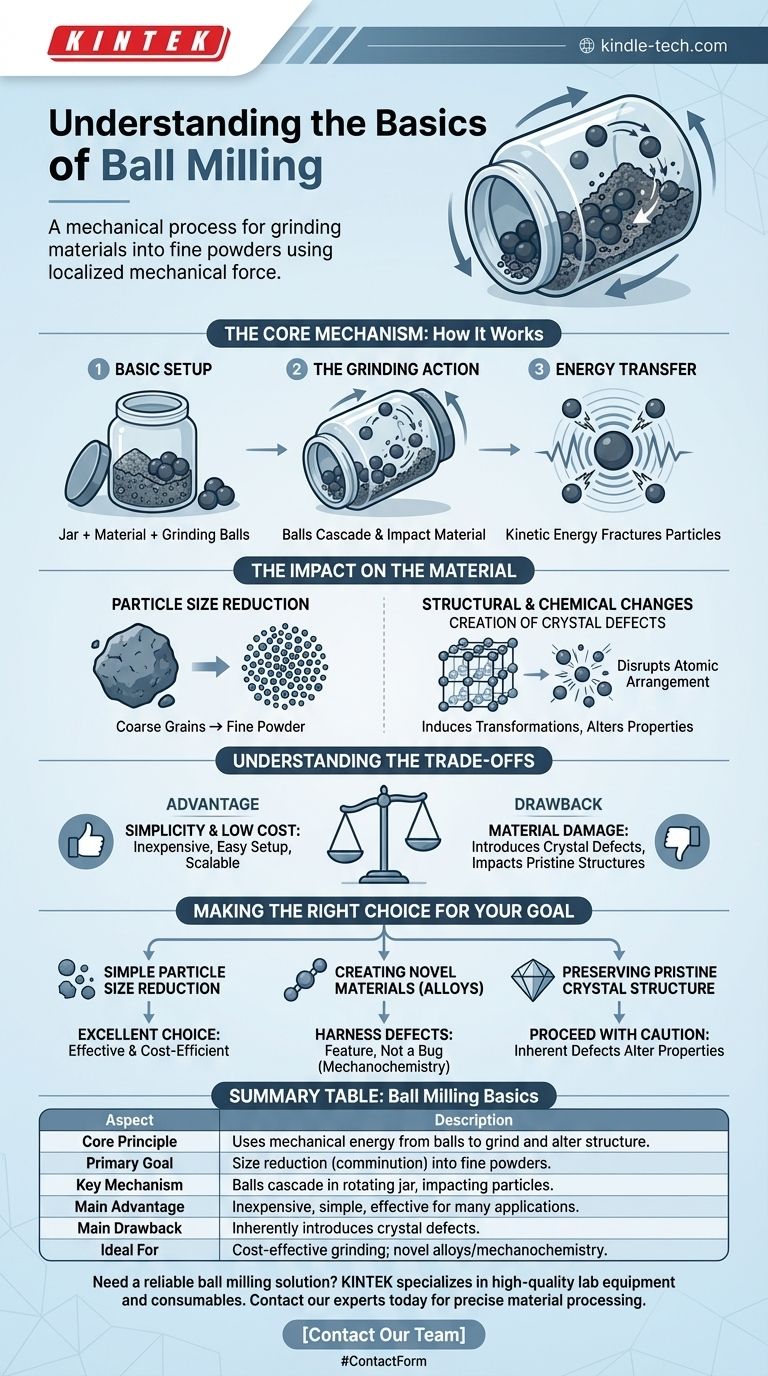

The Core Mechanism: How It Works

Ball milling is a straightforward yet powerful technique. Its effectiveness comes from the controlled chaos created inside the grinding vessel.

The Basic Setup

The system consists of a hollow vessel, or jar, which is partially filled with the material to be ground. Hard balls, known as the grinding media, are then added to the jar. The jar and balls are often made of the same durable material to minimize contamination.

The Grinding Action

The jar is sealed and rotated on its axis. As it rotates, the grinding balls are lifted up the side of the jar and then cascade or tumble back down, striking the material. This collision is where the grinding occurs, driven by the interaction between the balls, the particles, and the jar wall.

Energy Transfer

This entire process is a direct transfer of mechanical energy. The kinetic energy from the falling balls is imparted to the material particles, causing them to fracture, deform, and break down. All resulting changes in the material are a direct consequence of this energy input.

The Impact on the Material

While the primary goal is often size reduction, the intense energy involved has deeper effects on the material being processed.

Particle Size Reduction

The most immediate and obvious outcome is the comminution, or size reduction, of the source material. This can turn coarse grains or chunks into a fine, uniform powder.

Structural and Chemical Changes

The mechanical energy is powerful enough to do more than just break particles. It can induce structural transformations and even trigger chemical reactions within the material, a field often referred to as mechanochemistry.

Creation of Crystal Defects

A key side effect of ball milling is the introduction of crystal defects. The intense, repeated impacts disrupt the perfect, orderly arrangement of atoms in a crystalline material. This can alter the material's physical, chemical, and electronic properties.

Understanding the Trade-offs

Like any technical process, ball milling comes with a distinct set of advantages and inherent limitations that must be considered.

The Primary Advantage: Simplicity

The main benefits of ball milling are that it is inexpensive and relatively easy to perform. The equipment is not overly complex, and the process can be scaled for various applications, making it highly accessible.

The Inherent Drawback: Material Damage

The creation of crystal defects is the most significant drawback. While sometimes desirable for specific applications like creating alloys, these defects are often considered damage. They can negatively impact the performance of materials where a perfect crystal structure is critical.

Making the Right Choice for Your Goal

Ball milling is a versatile tool, but its suitability depends entirely on your end goal and how you manage its effects.

- If your primary focus is simple and low-cost particle size reduction: Ball milling is an excellent and highly effective choice.

- If your primary focus is creating novel alloys or amorphous materials: The mechanical energy and induced defects are not a bug but a feature that can be harnessed.

- If your primary focus is preserving a material's pristine crystal structure: You must proceed with caution, as ball milling will inherently introduce defects that can alter its fundamental properties.

Ultimately, ball milling is a powerful process for manipulating materials once you understand its direct and indirect consequences.

Summary Table:

| Aspect | Description |

|---|---|

| Core Principle | Uses mechanical energy from grinding balls to reduce particle size and alter material structure. |

| Primary Goal | Size reduction (comminution) of materials into fine powders. |

| Key Mechanism | Balls cascade inside a rotating jar, impacting and fracturing material particles. |

| Main Advantage | Inexpensive, simple setup, and effective for various applications. |

| Main Drawback | Inherently introduces crystal defects, which can damage pristine materials. |

| Ideal For | Cost-effective grinding; creating novel alloys or amorphous materials (mechanochemistry). |

Need a reliable ball milling solution for your lab? KINTEK specializes in high-quality lab equipment, including ball mills and consumables, designed for precise and efficient material processing. Whether your goal is simple size reduction or advanced mechanochemistry, our experts can help you select the right equipment to achieve your desired results. Contact our team today to discuss your specific application and ensure optimal performance!

Visual Guide

Related Products

- Laboratory Planetary Ball Mill Rotating Ball Milling Machine

- Stainless Steel Laboratory Ball Mill for Dry Powder and Liquid with Ceramic Polyurethane Lining

- Laboratory Horizontal Planetary Ball Mill Milling Machine

- High Energy Planetary Ball Mill for Laboratory Horizontal Tank Type Milling Machine

- High Energy Planetary Ball Mill Milling Machine for Laboratory

People Also Ask

- What is the working principle of planetary ball mill? Unlock High-Energy Grinding for Nanoscale Results

- What size are planetary mill particles? Achieve Nanoscale Precision for Your Materials

- How does a planetary mill work? Harnessing High-Energy Impact for Nano-Grinding

- What is the function of a planetary ball mill for c-LLZO precursors? Master Solid Electrolyte Prep

- What are the disadvantages of planetary ball mill? Key Drawbacks in Energy, Noise, and Wear