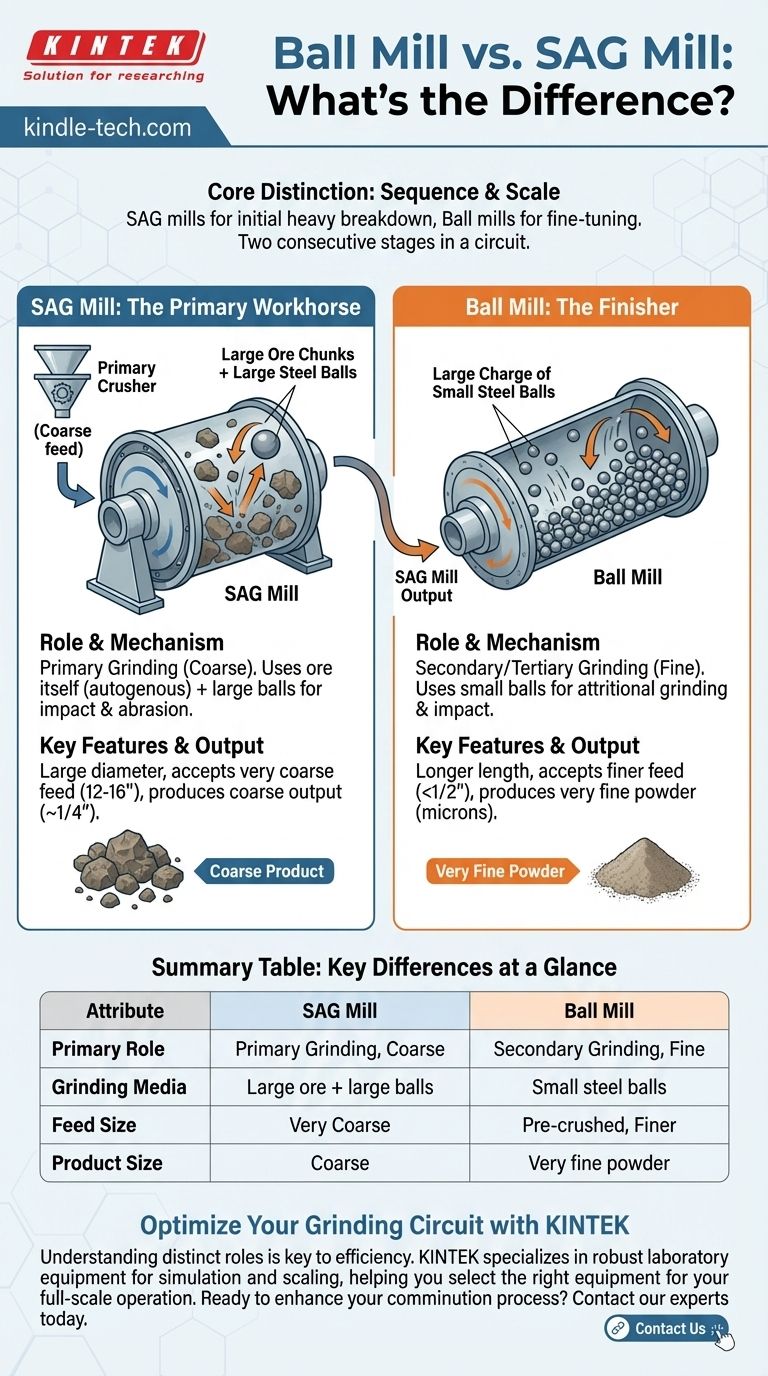

In short, the primary difference lies in their role and grinding media. A SAG (Semi-Autogenous Grinding) mill is a primary grinder that uses large chunks of the ore itself mixed with a few large steel balls to perform the initial, coarse size reduction. A ball mill is typically a secondary grinder that uses a large charge of smaller steel balls to reduce pre-crushed ore to a very fine powder.

The core distinction is one of sequence and scale. SAG mills perform the heavy, initial breakdown of large rocks, while ball mills handle the subsequent fine-tuning to produce a final, powdered product. They are not competing technologies but are often two consecutive stages in the same mineral processing circuit.

The Role of a SAG Mill: The Primary Workhorse

A SAG mill is the first major step in the grinding process after primary crushing. Its purpose is to take large, coarse ore and break it down significantly.

Grinding Mechanism and Media

A SAG mill is a large rotating drum that tumbles the ore. The "semi-autogenous" name comes from its grinding media: it primarily uses the ore itself (autogenous grinding) for impact and abrasion, supplemented by a small charge of large-diameter steel balls (semi-). These balls, typically 4-6 inches in diameter, help break the largest and toughest rocks.

Position in the Circuit

The SAG mill sits at the front end of the grinding circuit. It receives ore directly from the primary crusher and its output is then fed to the next stage, which is often a ball mill. Its large size allows it to handle a wide range of feed particle sizes.

Output Product

The product from a SAG mill is significantly smaller than what went in, but it is still relatively coarse. It is not a finished product but an intermediate material prepared for the next stage of grinding.

The Role of a Ball Mill: The Finisher

Once the SAG mill has done its job, the ball mill takes over to achieve the final, desired particle size needed for mineral liberation.

Grinding Mechanism and Media

Like a SAG mill, a ball mill is a rotating drum. However, its grinding chamber is filled with a much higher volume (typically 30-45%) of small steel balls. As the drum rotates, these balls cascade and tumble, creating countless impact and abrasion points that grind the ore down to a fine slurry. The references' mention of a tube mill using media and water is analogous to this wet grinding process.

Position in the Circuit

The ball mill is a secondary or tertiary grinding unit. It cannot handle the large, coarse feed that a SAG mill can. Instead, it requires a pre-processed feed with a controlled, smaller particle size.

Output Product

The ball mill produces a very fine, consistent slurry. The goal is to reduce the material to a specific "grind size," which is the optimal particle size for the subsequent separation process (like flotation or leaching) to extract the valuable minerals.

Key Differences at a Glance

To truly understand their functions, it's best to compare their core attributes side-by-side.

Grinding Media

- SAG Mill: Primarily uses large chunks of the ore itself, with a small charge (5-15% of volume) of large steel balls.

- Ball Mill: Exclusively uses a large charge (30-45% of volume) of small steel balls.

Mill Dimensions

- SAG Mill: Characterized by a large diameter relative to its length. This promotes lifting and impact to break large rocks.

- Ball Mill: Tends to be longer relative to its diameter, maximizing the grinding action within the cascading media.

Feed vs. Product Size

- SAG Mill: Accepts very coarse feed (up to 12-16 inches) and produces a coarse product (around 1/4 inch).

- Ball Mill: Accepts a finer feed (less than 1/2 inch) and produces a very fine, powder-like product measured in microns.

Understanding the Trade-offs

Choosing between or combining these mills involves critical operational and economic decisions.

Efficiency and Complexity

A SAG mill circuit can simplify the overall process by reducing or eliminating the need for secondary and tertiary crushing stages. This can lower capital costs and create a more streamlined plant layout. However, SAG mills can be sensitive to changes in ore hardness, which can affect throughput and efficiency.

Control and Precision

A ball mill offers much more precise control over the final product size. In circuits where the downstream recovery process is highly sensitive to particle size, a ball mill is essential for optimization. The trade-off is that it requires a more complex upstream crushing circuit to prepare its feed.

Energy Consumption

Both types of mills are massive consumers of energy. However, the energy is applied differently. SAG mills use immense power for high-impact breakage, while ball mills apply sustained power for attritional grinding. The most energy-efficient plant designs carefully balance the work done by each type of mill.

Making the Right Choice for Your Goal

These mills are designed for different, yet complementary, tasks. The right choice depends entirely on your position in the comminution process.

- If your primary focus is reducing run-of-mine ore: The SAG mill is the correct starting point for coarse, primary grinding.

- If your primary focus is preparing a fine, consistent slurry for mineral separation: The ball mill is the essential tool for secondary, fine grinding.

- If your primary focus is designing a complete grinding circuit: You will almost certainly use both, with a SAG mill feeding a ball mill to efficiently take ore from coarse rock to fine powder.

Ultimately, these two mills form a powerful partnership for achieving the particle size reduction necessary for modern mineral extraction.

Summary Table:

| Attribute | SAG Mill | Ball Mill |

|---|---|---|

| Primary Role | Primary Grinding (Coarse) | Secondary Grinding (Fine) |

| Grinding Media | Large ore chunks + a few large steel balls | Large charge of small steel balls |

| Feed Size | Very coarse (up to 12-16 inches) | Pre-crushed, finer feed (< 1/2 inch) |

| Product Size | Coarse (~1/4 inch) | Very fine powder (microns) |

Optimize Your Grinding Circuit with KINTEK

Understanding the distinct roles of SAG and ball mills is the first step toward maximizing your mineral processing efficiency. Whether you are designing a new circuit or optimizing an existing one, selecting the right equipment is critical for throughput, energy consumption, and final product quality.

KINTEK specializes in supplying robust and reliable laboratory equipment for testing and research. Our range of milling solutions can help you accurately simulate and scale your grinding processes, ensuring you make the best equipment choices for your full-scale operation.

Ready to enhance your comminution process? Contact our experts today to discuss how KINTEK's lab equipment can support your grinding circuit design and optimization goals.

Visual Guide

Related Products

- Stainless Steel Laboratory Ball Mill for Dry Powder and Liquid with Ceramic Polyurethane Lining

- Laboratory Ball Mill Jar Mill with Metal Alloy Grinding Jar and Balls

- Laboratory Planetary Ball Mill Rotating Ball Milling Machine

- Laboratory Micro Tissue Grinding Mill Grinder

- Laboratory Horizontal Planetary Ball Mill Milling Machine

People Also Ask

- What is the primary function of a laboratory ball mill in msHAP post-processing? Achieve Precise Particle Refinement

- What are the technical advantages of using an automated mortar and pestle? Precision in Mechanochemical Synthesis

- What are the parameters of ball mill design? Master the 5 Key Variables for Optimal Grinding

- What is the role of laboratory-grade grinders and sieves in sample prep? Ensure High-Precision Corrosion Analysis

- What is the efficiency of ball milling? Unlocking Its Power Despite Energy Inefficiency

- Why is mechanochemical synthesis equipment essential for single-atom catalysts? Scale Your Production Efficiency

- What is the primary function of a ball mill in calcium thermal reduction? Optimize Your Raw Material Preparation

- How does a vibration mixing mill optimize composite cathode preparation? Achieve Superior Interface Density