Choosing the right surface finish is a critical engineering decision. At a fundamental level, the difference between these two processes lies in the material and method of application. Physical Vapor Deposition (PVD) is a vacuum-based process that deposits a very thin, highly durable film of metallic or ceramic material onto a surface, while powder coating involves electrostatically applying a thicker layer of polymer powder that is then cured with heat.

The decision between PVD and powder coating is not about which is "better," but which aligns with your product's specific requirements. PVD provides superior hardness and wear resistance in a micro-thin layer for high-performance parts, whereas powder coating delivers a cost-effective, protective, and highly decorative finish with a vast color palette.

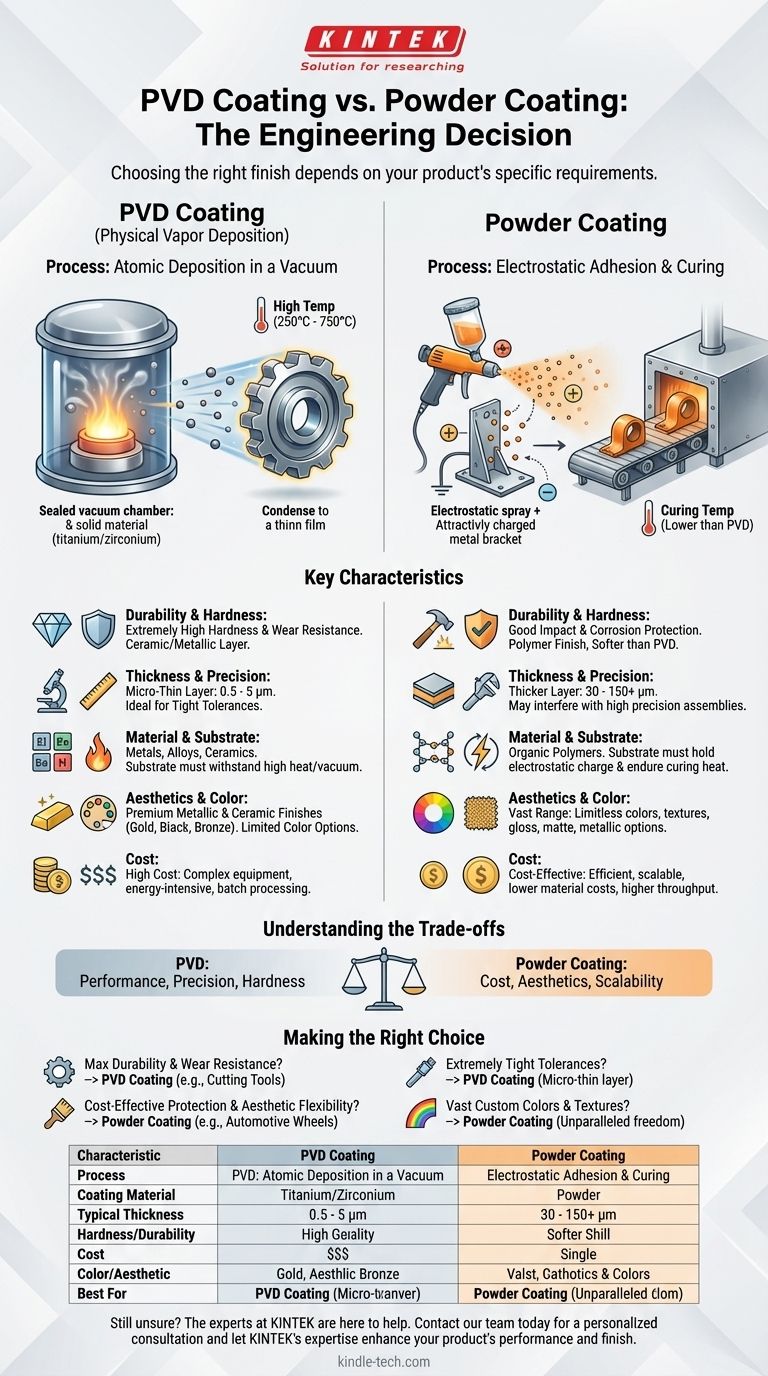

The Fundamental Difference: Application Process

To understand which finish is right for you, you must first grasp how radically different the two processes are. The method dictates the final properties of the coating.

PVD: Atomic Deposition in a Vacuum

Physical Vapor Deposition is a high-tech process that occurs inside a vacuum chamber. A solid source material, such as titanium or zirconium, is vaporized into its atomic or molecular state.

These vaporized particles then travel through the vacuum and condense onto the part being coated, forming a strong, bonded, and exceptionally dense thin film on its surface. This process is performed at high temperatures, often between 250°C and 750°C.

Powder Coating: Electrostatic Adhesion and Curing

Powder coating is a much different, non-vacuum process. It uses an electrostatic charge to apply a dry polymer powder to a surface.

The part to be coated is electrically grounded, and the powder is given a positive charge as it is sprayed. This charge differential causes the powder to adhere to the part. The coated part is then moved to a curing oven, where the heat melts the powder into a smooth, continuous, and uniform shell.

Comparing Key Performance Characteristics

The differences in application lead to vastly different performance outcomes. Each process excels in different areas.

Durability and Hardness

PVD is the clear winner for hardness and wear resistance. Because it deposits a ceramic or metallic layer, the resulting surface is extremely hard and resistant to abrasion, corrosion, and high temperatures.

Powder coating, being a polymer (plastic) finish, is much softer. While it provides excellent protection against corrosion and impacts, it is not designed to withstand the severe abrasive wear that a PVD coating can handle.

Thickness and Precision

PVD coatings are remarkably thin, typically measuring between 0.5 and 5 micrometers (μm). This makes PVD an ideal choice for components with tight engineering tolerances, such as cutting tools or intricate mechanical parts, as the coating will not alter the part's dimensions.

Powder coating creates a much thicker layer, often ranging from 30 to 150 micrometers or more. This thickness provides robust protection but can interfere with the assembly or function of parts that require high precision.

Material and Substrate Compatibility

PVD can deposit a wide array of materials, including metals, alloys, and ceramics. However, the substrate being coated must be able to withstand the high temperatures and vacuum environment of the PVD chamber.

Powder coating is limited to applying organic polymers. The primary requirement for the substrate is that it can hold an electrostatic charge and endure the lower curing temperatures without deforming.

Understanding the Trade-offs: Cost vs. Aesthetics

Your final decision will likely balance performance needs with budgetary and aesthetic goals.

The Cost Equation

PVD is significantly more expensive than powder coating. The cost is driven by the sophisticated vacuum equipment, high energy consumption, and slower, more complex batch processing.

Powder coating is a highly efficient and scalable industrial process. The equipment is less complex, material costs are lower, and throughput is much higher, making it a far more cost-effective solution for a wide range of applications.

Visual Finish and Color Options

Powder coating offers a nearly limitless range of options. You can achieve almost any color in the visible spectrum, along with a wide variety of textures and finishes, from high gloss to matte, metallic, and textured surfaces.

PVD provides a more limited, though often premium, palette of metallic and ceramic finishes like gold, black, bronze, and graphite. While the appearance is high-end, the customization for specific colors is far more restricted.

Making the Right Choice for Your Product

Choose the process that directly serves the primary goal of your component or product.

- If your primary focus is maximum durability and wear resistance: PVD is the superior choice for high-performance applications like cutting tools, medical implants, or firearm components.

- If your primary focus is cost-effective protection with aesthetic flexibility: Powder coating is the ideal solution for products like architectural metalwork, automotive wheels, and industrial equipment.

- If your component has extremely tight tolerances: The micro-thin nature of PVD is essential, as a thick powder coat could interfere with assembly or function.

- If you need a vast range of custom colors and textures: Powder coating offers unparalleled creative freedom that PVD cannot match.

By understanding the core principles of each process, you can confidently select the finish that provides the precise balance of performance, appearance, and cost for your application.

Summary Table:

| Characteristic | PVD Coating | Powder Coating |

|---|---|---|

| Process | Vacuum-based atomic deposition | Electrostatic spray & heat curing |

| Coating Material | Metals, Alloys, Ceramics | Polymer Powders |

| Typical Thickness | 0.5 - 5 μm | 30 - 150+ μm |

| Hardness / Durability | Extremely high, wear-resistant | Good impact & corrosion resistance |

| Cost | High | Cost-effective |

| Color & Aesthetic Options | Limited metallic/ceramic finishes | Vast range of colors & textures |

| Best For | High-performance parts, tight tolerances | Decorative finishes, cost-effective protection |

Still unsure which coating is right for your components? The experts at KINTEK are here to help. We specialize in providing advanced lab equipment and consumables for surface engineering and material testing. Whether you're developing high-performance tools or consumer products, we can help you select the right process to meet your specifications for durability, aesthetics, and budget. Contact our team today for a personalized consultation and let KINTEK's expertise enhance your product's performance and finish.

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Custom CVD Diamond Coating for Lab Applications

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

- Oil Free Diaphragm Vacuum Pump for Laboratory and Industrial Use

People Also Ask

- What are the advantages of PECVD? Enable Low-Temperature, High-Quality Thin-Film Deposition

- How does RF power create plasma? Achieve Stable, High-Density Plasma for Your Applications

- How are PECVD and CVD different? A Guide to Choosing the Right Thin-Film Deposition Process

- Why is PECVD environment friendly? Understanding the Eco-Friendly Benefits of Plasma-Enhanced Coating

- What is an example of PECVD? RF-PECVD for High-Quality Thin Film Deposition