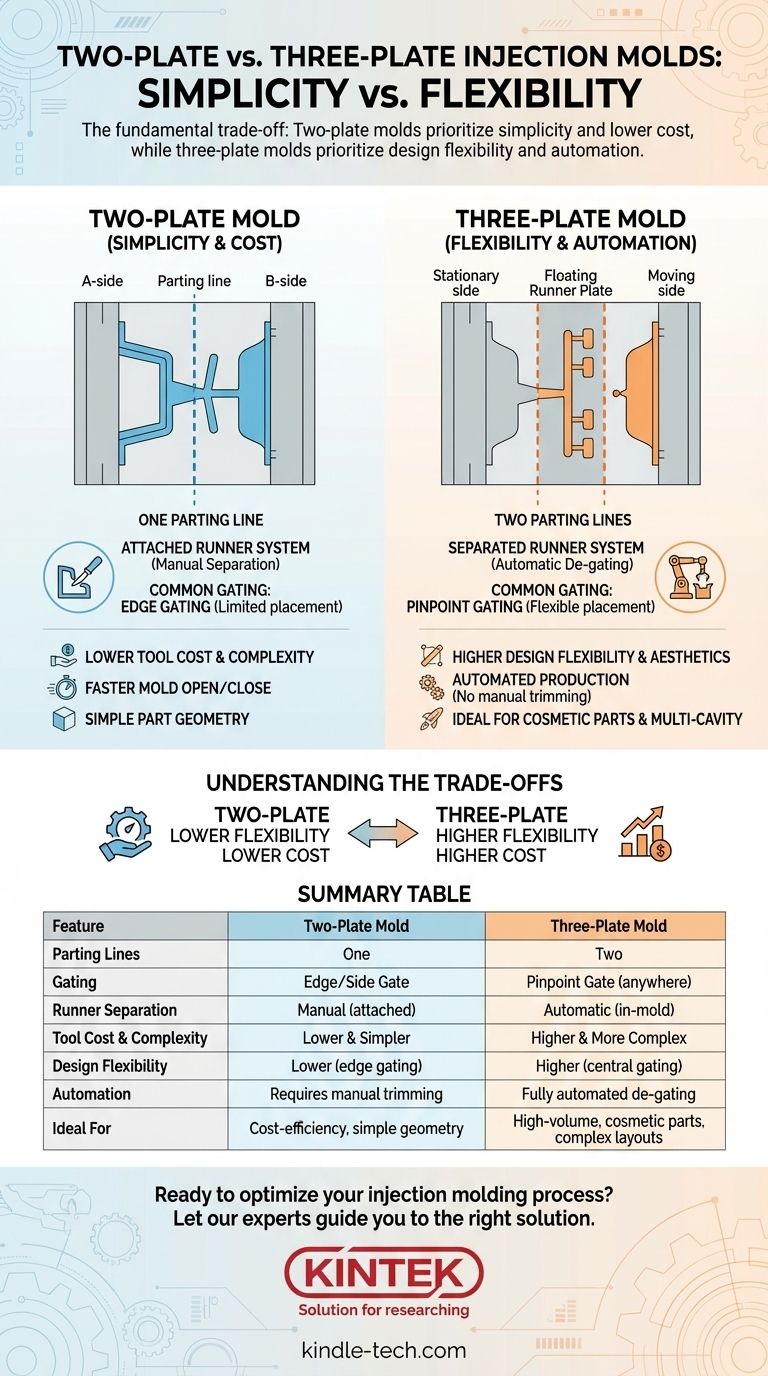

At its core, the difference between a two-plate and a three-plate injection mold lies in how the final part is separated from the plastic delivery system, known as the runner. A two-plate mold is simpler, with one parting line where the part and runner are ejected together. A three-plate mold is more complex, using two parting lines to automatically separate the runner from the part inside the mold before ejection.

The choice is a fundamental trade-off. Two-plate molds prioritize simplicity and lower tool cost, while three-plate molds prioritize design flexibility and automated production, often at a higher initial expense.

The Anatomy of a Two-Plate Mold

A two-plate mold is the most common and straightforward type of injection mold. It consists of two primary halves, often called the A-side (cavity) and B-side (core), which meet at a single plane.

How It Works: One Parting Line

When the mold opens, it separates along a single parting line. The molded part and the attached runner system are pushed out of the mold cavity together by ejector pins.

The Attached Runner System

In this design, the channels that carry the molten plastic to the part—the sprue and runners—are in the same plane as the part itself. Consequently, the solidified runner remains attached to the part upon ejection.

Common Gating Strategy: Edge Gating

Because the runner is on the parting line, the gate (the small opening connecting the runner to the part) is almost always located on the part's edge. This is known as an edge gate or side gate. This often requires a secondary, manual operation to trim the runner and gate from the finished part.

The Advanced Design of a Three-Plate Mold

A three-plate mold introduces an additional plate, creating a more complex tool with greater functional capability. It consists of a stationary side, a moving side, and a "floating" runner plate in between.

How It Works: Two Parting Lines

This design features two distinct parting lines. As the mold begins to open, the first parting line opens to break the gate connection between the part and the runner. As it opens further, the second parting line opens to eject the now-separate runner system.

The Separated Runner System

The key innovation is that the runner system is contained in its own plane on the runner plate. This allows the mold to automatically shear the gate and separate the runner from the part during the mold's opening sequence. This is often referred to as automatic de-gating.

The Power of Pinpoint Gating

This separation enables the use of pinpoint gates, which can be placed almost anywhere on the surface of the part, not just the edge. This is ideal for filling large parts centrally, gating on non-cosmetic surfaces, or feeding multiple cavities symmetrically for balanced filling.

Understanding the Trade-offs

Choosing between these two mold types has significant consequences for cost, design, and production efficiency.

Design Flexibility and Aesthetics

A three-plate mold offers far greater flexibility. It allows you to place a gate in the center of a round part to ensure uniform flow or hide it on a non-visible surface, preserving the part's cosmetic appearance.

A two-plate mold is more restrictive. The gate location is limited to the part's perimeter, which may not be ideal for filling or can leave an undesirable cosmetic blemish.

Tool Cost and Complexity

Two-plate molds are simpler in construction, have fewer components, and are therefore less expensive and faster to manufacture.

Three-plate molds are inherently more complex due to the extra plate and the mechanisms required to control the two separate opening actions. This results in a significantly higher initial tooling cost and more maintenance.

Cycle Time and Automation

A three-plate mold enables a fully automated process. By ejecting the part and runner separately, it eliminates the need for a person or robot to manually trim the runner. This can reduce the overall production cost per part, especially in high-volume runs.

A two-plate mold may have a faster mold open-and-close time, but the total cycle time can be longer once the necessary manual runner removal is factored in.

Material Waste

The runner system in a three-plate mold is often larger and more complex than in a two-plate mold, which can lead to more wasted plastic material per cycle. This is a critical consideration unless a more advanced (and even more expensive) hot runner system is used.

Making the Right Choice for Your Goal

Your part's specific requirements will dictate the correct mold design.

- If your primary focus is cost-efficiency and simple part geometry: A two-plate mold is the superior choice, especially if a gate mark on the part's edge is acceptable and production volumes are low to moderate.

- If your primary focus is design flexibility and cosmetic appearance: A three-plate mold is necessary for parts that require central gating, have critical aesthetic surfaces, or are intended for high-volume, automated production.

- If you are molding multiple, small identical parts in one shot: A three-plate mold allows for a balanced runner layout that feeds each cavity from its ideal center point, ensuring higher quality and consistency.

Understanding this fundamental choice between simplicity and flexibility is the first step toward designing a part that is truly optimized for manufacturing.

Summary Table:

| Feature | Two-Plate Mold | Three-Plate Mold |

|---|---|---|

| Parting Lines | One | Two |

| Gating | Edge/Side Gate | Pinpoint Gate (anywhere) |

| Runner Separation | Manual (attached) | Automatic (in-mold) |

| Tool Cost & Complexity | Lower & Simpler | Higher & More Complex |

| Design Flexibility | Lower (edge gating) | Higher (central gating) |

| Automation | Requires manual trimming | Fully automated de-gating |

| Ideal For | Cost-efficiency, simple geometry | High-volume, cosmetic parts, complex layouts |

Ready to optimize your injection molding process? The choice between a two-plate and three-plate mold is critical for your project's success, impacting cost, quality, and production speed. At KINTEK, we specialize in providing the precise lab equipment and consumables needed for prototyping and manufacturing, helping you make informed decisions for your plastic parts. Let our experts guide you to the right solution. Contact KINTEK today to discuss your specific laboratory and production needs!

Visual Guide

Related Products

- Special Heat Press Mold for Lab Use

- Cylindrical Press Mold for Lab Applications

- Polygon Press Mold for Lab

- Special Shape Press Mold for Lab

- Carbide Lab Press Mold for Laboratory Applications

People Also Ask

- How do graphite molds contribute to the chemical environment during the vacuum hot pressing of Cu-Cr-Nb alloys?

- Why is compression molding important? Unmatched Strength for Large, Durable Parts

- Why is PEEK selected as the cylinder material for pellet cell molds? Achieve High-Pressure Stability & Data Accuracy

- What role do graphite molds play during vacuum hot press sintering? Optimize TiCN-Reinforced Composites

- What are the primary functions of graphite molds in the 2000°C hot-pressing? Optimize Your C-SiC-B4C-TiB2 Composites

- What is the price of a mold press machine? Understand the True Cost & Investment for Your Production

- What are the functions of a high-purity graphite die-punch assembly in the vacuum hot press sintering process?

- What is the function of graphite molds in sintering copper-diamond composites? Optimize Precision and Density