To initiate sputtering, the kinetic energy of the bombarding ions must be significantly higher than normal thermal energies. While the fundamental energy needed to dislodge a single atom is typically 10-40 electron volts (eV), the overall system requires much higher inputs to create and accelerate these ions, such as DC voltages of 3-5 kilovolts (kV) or radio frequencies (RF) around 14 MHz.

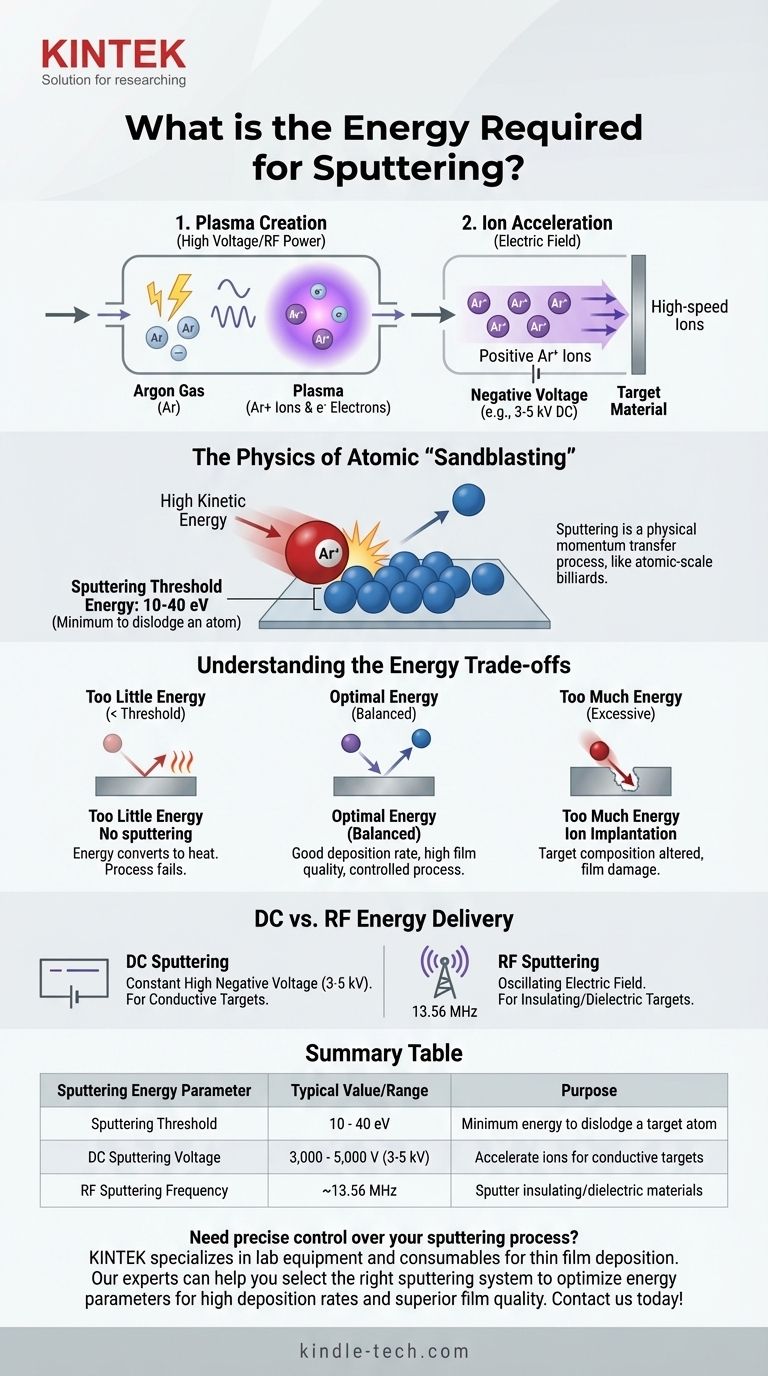

The "energy" for sputtering is not a single value but a two-part process. First, high voltage or RF power is used to create a plasma from a gas like Argon. Then, an electric field accelerates ions from this plasma, giving them the high kinetic energy needed to physically eject atoms from a target material.

The Physics of Atomic "Sandblasting"

Sputtering is fundamentally a physical momentum transfer process, often compared to an atomic-scale game of billiards. The goal is to give an ion enough kinetic energy to knock atoms loose from a solid material, known as the "target."

The Sputtering Threshold

For sputtering to occur, the incoming ion must have enough energy to overcome the forces that bind the target atoms together. This minimum energy is called the sputtering threshold energy.

This threshold is typically in the range of 10 to 40 eV, depending on the ion and the target material. Below this energy, the ion will simply bounce off or transfer its energy as heat.

Creating and Accelerating Ions

You cannot simply inject 40 eV ions into a chamber. Instead, you must create them in-situ from an inert gas, most commonly Argon (Ar).

A high voltage (in DC sputtering) or a strong radio-frequency field (in RF sputtering) is applied. This energy strips electrons from the Argon atoms, creating a glowing, ionized gas called a plasma, which is a mix of positive Argon ions (Ar+) and free electrons.

The Role of High Voltage

Once the plasma is formed, a strong negative voltage is applied to the target material. In DC sputtering, this is typically 3,000 to 5,000 volts (3-5 kV).

Because opposites attract, the positive Argon ions in the plasma are forcefully accelerated across this electric field and smash into the negatively charged target. This is how they gain the kinetic energy—far exceeding the basic sputtering threshold—needed to efficiently eject target atoms.

Understanding the Energy Trade-offs

The amount of energy used is not arbitrary; it's a critical process parameter that directly impacts the outcome. Choosing the right energy level involves balancing competing factors.

Consequence of Too Little Energy

If the energy of the bombarding ions is below the sputtering threshold, no sputtering will occur. The process will fail, and the energy will only contribute to heating the target. Even slightly above the threshold, the sputtering rate (the amount of material removed over time) will be impractically slow.

Consequence of Too Much Energy

Excessively high ion energies can be counterproductive. Instead of cleanly ejecting a target atom, a very high-energy ion may become embedded or implanted deep within the target material.

This "ion implantation" effectively buries the bombarding particle, failing to sputter material and instead altering the composition of the target itself. It can also cause damage to the crystal structure of the growing film on your substrate.

DC vs. RF Energy Delivery

The method of energy delivery depends on the target material's electrical properties.

- DC (Direct Current) Sputtering: Uses a constant, high negative voltage. This is simple and effective but only works for electrically conductive targets.

- RF (Radio Frequency) Sputtering: Uses an oscillating electric field (e.g., 13.56 MHz). This is essential for insulating or dielectric targets, as it prevents a buildup of positive charge on the target surface that would otherwise repel the bombarding ions.

Applying This to Your Goal

Your choice of energy parameters should be directly tied to the specific film you are trying to create.

- If your primary focus is a high deposition rate: Use higher ion energies and currents to maximize the sputtering yield, but stay below the point of significant ion implantation.

- If your primary focus is film quality and density: A moderate energy level is often optimal, as it provides good sputtering rates without causing excessive damage or gas incorporation in the growing film.

- If you are sputtering an electrical insulator (like SiO₂): You must use an RF power source, as a DC voltage will not be effective.

Ultimately, controlling sputtering energy is about precisely managing the momentum of ions to build your desired material, one atom at a time.

Summary Table:

| Sputtering Energy Parameter | Typical Value/Range | Purpose |

|---|---|---|

| Sputtering Threshold | 10 - 40 eV | Minimum energy to dislodge a target atom |

| DC Sputtering Voltage | 3,000 - 5,000 V (3-5 kV) | Accelerate ions for conductive targets |

| RF Sputtering Frequency | ~13.56 MHz | Sputter insulating/dielectric materials |

Need precise control over your sputtering process? KINTEK specializes in lab equipment and consumables for thin film deposition. Our experts can help you select the right sputtering system to optimize energy parameters for high deposition rates and superior film quality. Contact us today to discuss your laboratory's specific needs!

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Evaporation Boat for Organic Matter

- VHP Sterilization Equipment Hydrogen Peroxide H2O2 Space Sterilizer

People Also Ask

- What is the temperature of PECVD deposition? Achieve High-Quality Films at Low Temperatures

- How does RF power create plasma? Achieve Stable, High-Density Plasma for Your Applications

- What is an example of PECVD? RF-PECVD for High-Quality Thin Film Deposition

- What are the advantages of PECVD? Enable Low-Temperature, High-Quality Thin-Film Deposition

- What is the difference between PECVD and sputter? Choose the Right Thin-Film Deposition Method