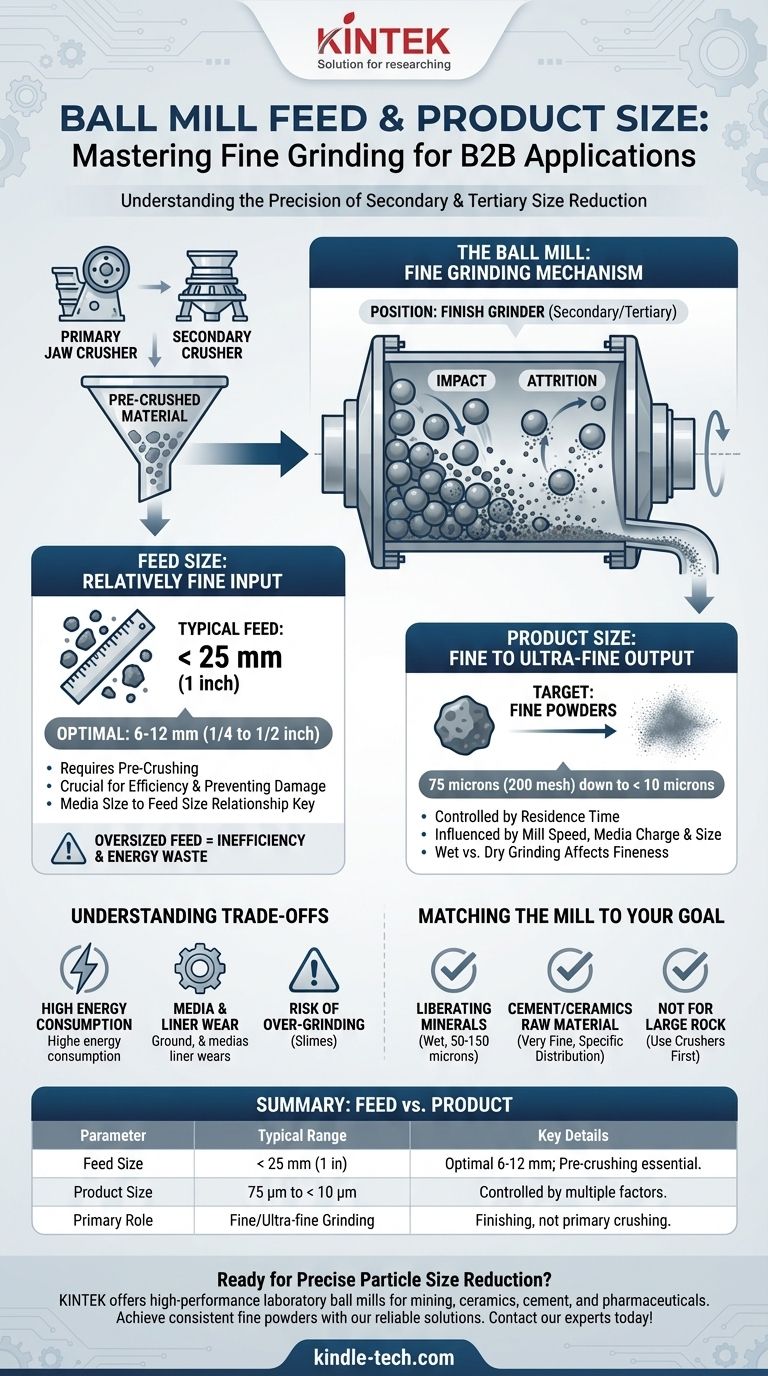

In short, a typical ball mill is designed to process a relatively fine feed, generally under 25 mm (1 inch) in diameter. It excels at grinding this material down to a fine or ultra-fine product size, often ranging from 75 microns (200 mesh) down to as low as 10 microns or even finer depending on the application and processing time.

The core function of a ball mill is not coarse crushing but fine grinding. Its feed and product size specifications reflect its role as a secondary or tertiary size-reduction machine, taking pre-crushed material and transforming it into a fine powder.

Understanding the Role of a Ball Mill

A ball mill is a specialized tool within a larger material processing circuit. Understanding its specific purpose is key to understanding its size limitations.

The Grinding Mechanism: Impact and Attrition

Ball mills reduce particle size through two primary actions. Impact occurs when the grinding balls are lifted by the rotating shell and cascade down, striking the material. Attrition occurs as material is caught and ground between the tumbling balls. This combination is highly effective for producing very fine particles.

Position in the Comminution Circuit

Ball mills are almost never the first stage of size reduction. They are finish grinders. Material is first broken down by primary and secondary crushers (like jaw or cone crushers) before being fed into a ball mill for the final grinding stage.

Defining Feed Size Limitations

The maximum feed size for a ball mill is not arbitrary; it is dictated by the physics of the grinding process.

The Key Relationship: Feed vs. Media Size

The grinding media (the steel or ceramic balls) must be large and heavy enough to possess sufficient kinetic energy to fracture the feed particles upon impact. A small ball simply cannot break a large piece of rock.

As a general rule of thumb, the diameter of the largest feed particle should be a small fraction of the diameter of the largest grinding balls used in the mill.

Typical Feed Size Range

For most industrial applications, the top feed size for a ball mill is less than 25 mm (1 inch). For optimal efficiency and to prevent damage, a feed size of around 6-12 mm (1/4 to 1/2 inch) is often preferred.

Why Pre-Crushing is Essential

Feeding oversized material to a ball mill is inefficient and counterproductive. The mill will expend a significant amount of energy simply breaking down a few large pieces, starving the rest of the charge and dramatically reducing overall throughput. This is why a crusher must prepare the material first.

Achieving the Desired Product Size

A ball mill's primary strength is its ability to produce a consistently fine output. The final particle size is not a fixed number but a variable controlled by several factors.

The Target: Fine to Ultra-Fine Powders

Ball mills reliably produce powders in the fine particle range. A typical product might be specified as 80% passing 75 microns (200 mesh).

In applications requiring even smaller particles, such as in the ceramic or pigment industries, extended grinding times in a ball mill can achieve ultra-fine product sizes of 20 microns or less.

Factors Controlling Final Particle Size

The operator can control the final product size by adjusting several key parameters:

- Residence Time: The longer the material stays in the mill, the finer it becomes.

- Mill Speed: Affects the cascading action of the balls (impact vs. attrition).

- Media Charge & Size: The volume, size, and density of the balls influence grinding energy.

- Wet vs. Dry Grinding: Wet grinding is generally more efficient for producing ultra-fine particles and helps prevent material from coating the media.

Understanding the Trade-offs

While highly effective, ball mills are not without their operational considerations. Being aware of these trade-offs is crucial for process design.

High Energy Consumption

Fine grinding is an energy-intensive process. The energy required to reduce particle size increases exponentially as the target size decreases. Ball mills are among the largest consumers of power in a mineral processing plant.

Media and Liner Wear

The constant tumbling and impact result in the gradual wear of both the grinding media and the mill's internal protective liners. These are consumable items that represent a significant ongoing operational cost.

The Risk of Over-Grinding

Grinding material finer than necessary is a waste of energy and can create problems in downstream processes. For example, in mineral flotation, excessive ultra-fine particles ("slimes") can reduce recovery efficiency.

Matching the Mill to Your Grinding Goal

To make an informed decision, align the mill's capabilities with your specific objective.

- If your primary focus is liberating valuable minerals from ore: A wet grinding ball mill is the industry standard for reducing ore to the fine sizes (e.g., 50-150 microns) required for efficient separation.

- If your primary focus is producing raw material for cement or ceramics: A ball mill is the ideal tool for achieving the very fine, specific particle size distributions required for these products.

- If your primary focus is reducing large, run-of-mine rock (e.g., >50 mm): A ball mill is the wrong tool; you must first use a primary crusher like a jaw crusher, followed potentially by a cone crusher.

Ultimately, a ball mill is a precision instrument for the final stage of material pulverization, not a brute-force rock breaker.

Summary Table:

| Parameter | Typical Range | Key Details |

|---|---|---|

| Feed Size | < 25 mm (1 in) | Optimal feed is 6-12 mm; requires pre-crushed material. |

| Product Size | 75 microns to < 10 microns | Fineness controlled by residence time, media size, and mill speed. |

| Primary Role | Fine/Ultra-fine Grinding | Secondary/tertiary machine for finishing, not primary crushing. |

Ready to achieve precise particle size reduction in your lab or processing plant? KINTEK specializes in high-performance laboratory ball mills and grinding equipment designed for efficiency and reliability. Whether you're in mining, ceramics, cement, or pharmaceuticals, our solutions help you produce consistent fine and ultra-fine powders. Contact our experts today to discuss your specific grinding needs and find the perfect ball mill for your application!

Visual Guide

Related Products

- Stainless Steel Laboratory Ball Mill for Dry Powder and Liquid with Ceramic Polyurethane Lining

- Laboratory Ball Mill Jar Mill with Metal Alloy Grinding Jar and Balls

- Laboratory Single Horizontal Jar Mill

- Laboratory Four-Body Horizontal Jar Mill

- High Energy Planetary Ball Mill Milling Machine for Laboratory

People Also Ask

- What role does a planetary ball mill play in eggshell fertilizer production? Unlock Superior Chemical Reactivity

- What is the product size of a ball mill? Achieve Micron-Level Precision for Your Materials

- Why use ball milling for NMC cathode materials? Achieve Precision Particle Sizing for Composite Cathodes

- What is the function of ball milling equipment in NZSSP electrolyte preparation? Optimize NASICON Solid-State Synthesis

- Why is a laboratory ball mill used in Co-Ni catalyst research? Optimize CO2 Conversion with Precise Milling