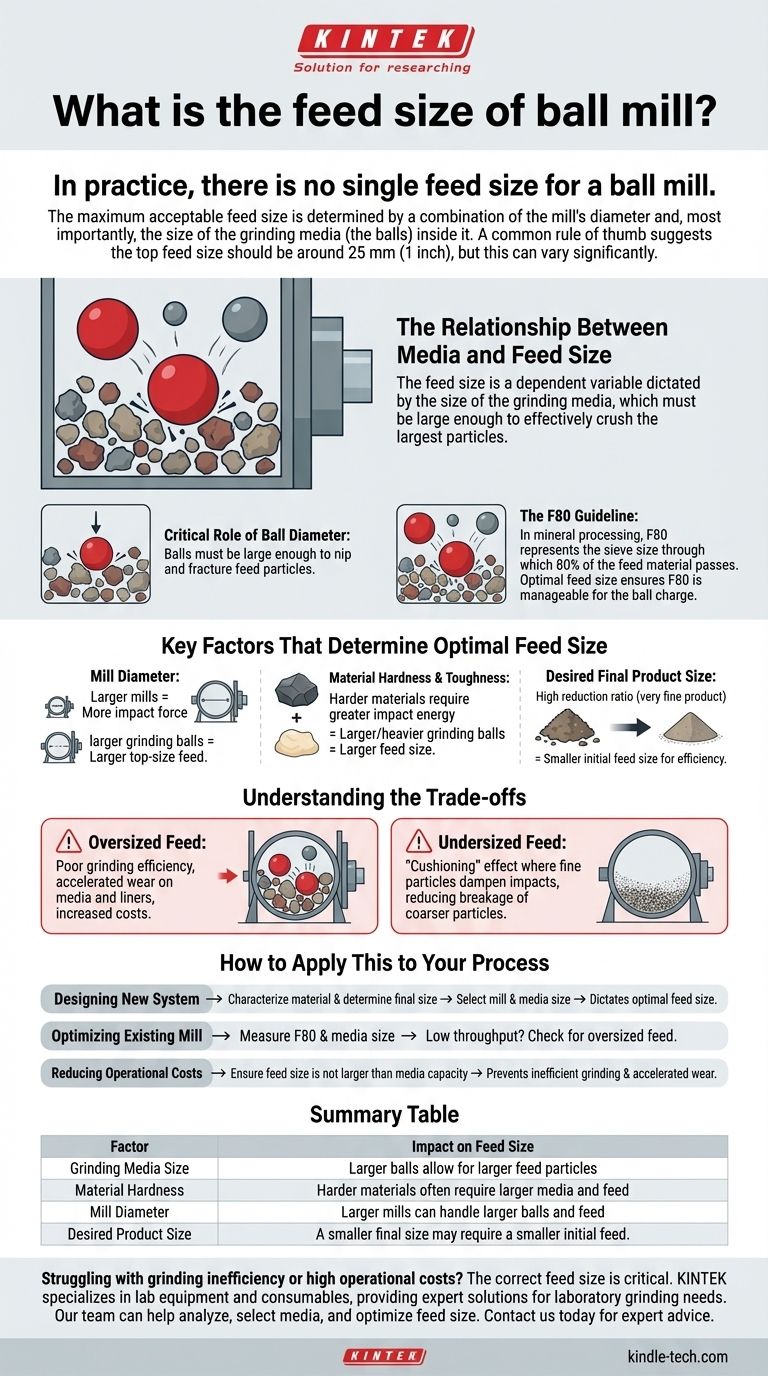

In practice, there is no single feed size for a ball mill. The maximum acceptable feed size is determined by a combination of the mill's diameter and, most importantly, the size of the grinding media (the balls) inside it. A common rule of thumb suggests the top feed size should be around 25 mm (1 inch), but this can vary significantly.

The core principle to understand is that the feed size for a ball mill is not a standalone specification. It is a dependent variable dictated by the size of the grinding media, which must be large enough to effectively crush the largest particles of the incoming material.

The Relationship Between Media and Feed Size

A ball mill works by causing grinding media (balls) to impact and abrade material particles, breaking them down. For this to happen efficiently, the balls must be able to "nip" and fracture the feed particles.

The Critical Role of Ball Diameter

The size of the grinding balls directly limits the maximum size of the feed material. If the feed particles are too large relative to the balls, the balls will simply slide over them or push them aside rather than breaking them.

This leads to a dramatic drop in grinding efficiency and an increase in wear on the mill's internal lining.

The F80 Guideline

In mineral processing, a common metric used is F80, which represents the sieve size through which 80% of the feed material passes. The F80 value is a more practical measure of feed size than just the absolute largest particle.

The optimal feed size is often determined by ensuring that the F80 of the feed is small enough for the existing ball charge to handle effectively.

Key Factors That Determine Optimal Feed Size

The ideal feed size is a balance of several interconnected variables within the grinding circuit. Understanding these factors is key to optimizing the entire process.

Mill Diameter

Larger diameter mills can generate more impact force and can accommodate larger grinding balls. Consequently, a larger mill can typically handle a larger top-size feed compared to a smaller mill.

Material Hardness and Toughness

The physical properties of the material being ground are critical. Harder, tougher materials require greater impact energy to fracture. This often necessitates the use of larger, heavier grinding balls, which in turn allows for a larger feed size.

Conversely, softer or more friable materials can be broken by smaller media, which may require a smaller initial feed size for optimal performance.

Desired Final Product Size

The required fineness of the final product also influences the ideal feed size. The reduction ratio is the ratio of the feed size to the product size (e.g., F80/P80).

If a very large reduction ratio is required (i.e., making a very fine powder from a coarse feed), it is often more efficient to start with a smaller feed size. Trying to achieve a massive size reduction in a single pass can be highly inefficient.

Understanding the Trade-offs

Choosing the wrong feed size has significant consequences for both performance and operational cost.

The Impact of Oversized Feed

Feeding material that is too large for the media charge is a common and costly mistake. It leads directly to poor grinding efficiency, as energy is wasted moving particles that aren't being broken.

It also causes accelerated wear on both the grinding media and the mill liners, increasing maintenance costs and downtime.

The Inefficiency of Undersized Feed

While less common, feeding material that is already very fine can also be inefficient. This can lead to a "cushioning" effect where the fine particles dampen the impacts of the grinding media, reducing the breakage rate of the remaining coarser particles.

This scenario often indicates that the upstream crushing circuit is doing too much work or that a different type of mill, designed for finer grinding, might be more appropriate.

How to Apply This to Your Process

Your approach to determining the correct feed size depends on whether you are designing a new circuit or optimizing an existing one.

- If your primary focus is designing a new system: First, characterize your material's hardness and determine the required final product size. This will inform the selection of the mill and the necessary grinding media size, which then dictates the optimal feed size.

- If your primary focus is optimizing an existing mill: Measure the size distribution (F80) of your current feed and the size of your grinding media. If you are experiencing low throughput, oversized feed is a primary suspect that must be addressed by adjusting the upstream crusher settings.

- If your primary focus is reducing operational costs: Ensure your feed size is never larger than what your media can handle. Preventing inefficient grinding and accelerated wear from oversized feed provides a significant return on investment.

Ultimately, viewing feed size as a critical variable in an interconnected system, rather than a fixed number, is the key to an efficient grinding operation.

Summary Table:

| Factor | Impact on Feed Size |

|---|---|

| Grinding Media Size | Larger balls allow for larger feed particles. |

| Material Hardness | Harder materials often require larger media and feed. |

| Mill Diameter | Larger mills can handle larger balls and feed. |

| Desired Product Size | A smaller final size may require a smaller initial feed. |

Struggling with grinding inefficiency or high operational costs?

The correct feed size is critical for your ball mill's performance and longevity. KINTEK specializes in lab equipment and consumables, providing expert solutions for laboratory grinding needs. Our team can help you analyze your process, select the right media, and optimize your feed size for superior results and cost savings.

Contact us today to discuss how we can enhance your grinding operation.

Visual Guide

Related Products

- Stainless Steel Laboratory Ball Mill for Dry Powder and Liquid with Ceramic Polyurethane Lining

- Laboratory Single Horizontal Jar Mill

- Laboratory Ball Mill Jar Mill with Metal Alloy Grinding Jar and Balls

- Laboratory Four-Body Horizontal Jar Mill

- Laboratory Planetary Ball Mill Rotating Ball Milling Machine

People Also Ask

- What is the product size of a ball mill? Achieve Micron-Level Precision for Your Materials

- What is the key role of a planetary ball mill for IZO targets? Achieve Atomic-Level Uniformity in Material Preparation

- How does a high-energy planetary ball mill facilitate the synthesis of sulfide glassy electrolytes? Achieve Amorphization

- Why use ball milling for NMC cathode materials? Achieve Precision Particle Sizing for Composite Cathodes

- What is the purpose of ball milling? A Versatile Tool for Material Synthesis and Modification