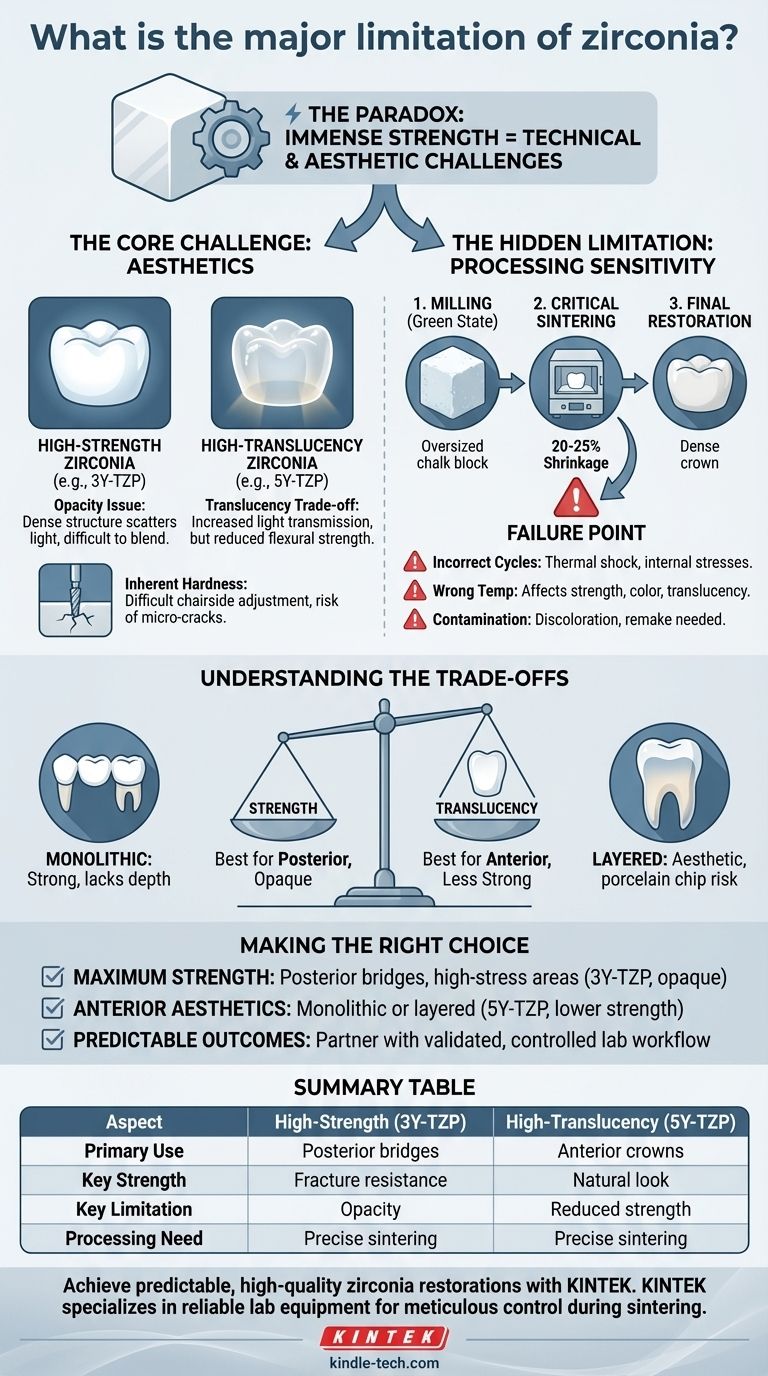

The single greatest limitation of zirconia is not a simple property but a fundamental paradox: its immense strength creates significant challenges in both aesthetics and technical processing. While often cited for its opacity, the true limitation lies in the extreme technical sensitivity required—especially during the critical sintering stage—to achieve a predictable and durable result.

Zirconia's defining strength is a double-edged sword. This strength makes the material inherently more opaque than other ceramics and demands a manufacturing process that is highly unforgiving. Small deviations, particularly in sintering, can compromise the final restoration's integrity, fit, and aesthetics.

The Core Challenge: Reconciling Strength and Aesthetics

The difficulties associated with zirconia stem from its unique crystalline structure, which is responsible for both its best and worst characteristics.

The Opacity Issue

Early forms of dental zirconia (like 3Y-TZP) have a tetragonal crystal structure that provides incredible flexural strength, making them highly resistant to fracture.

However, this dense crystal arrangement is also very effective at scattering light, which results in a bright, opaque appearance that can be difficult to blend with natural teeth.

The Rise of Translucent Zirconia

To address the aesthetic problem, newer formulations were developed (often called anterior or high-translucency zirconia, like 5Y-TZP).

These versions incorporate more cubic-phase crystals. This alteration allows more light to pass through, significantly improving translucency, but it comes at the cost of reduced flexural strength and fracture toughness.

Inherent Hardness and Adjustability

Zirconia is exceptionally hard, which is excellent for resisting wear. However, this makes it very difficult to cut or adjust in the clinic without specialized instruments.

Improper chairside adjustments with standard burs can introduce microscopic cracks or generate excessive heat, potentially leading to premature failure of the crown.

The Hidden Limitation: Technical Processing Sensitivity

The most significant source of zirconia failures happens long before the restoration reaches the patient. The material's reliability is entirely dependent on the precision of the laboratory process.

Why Sintering is So Critical

Zirconia restorations are first milled from a pre-sintered, chalk-like block (the "green state"). This oversized restoration is then heated in a specialized oven in a process called sintering.

During sintering, the zirconia particles fuse together, and the restoration shrinks by 20-25% to its final, dense, and incredibly strong state. This step is where most critical errors occur.

The Impact of Incorrect Sintering Cycles

The manufacturer's instructions for sintering protocols are extremely specific for a reason. Any deviation can be catastrophic.

- Heating or cooling too quickly: This can cause thermal shock, leading to internal stresses and cracks that are invisible to the naked eye but will cause the restoration to fail under normal function.

- Incorrect final temperature: Firing too hot or too cool can affect the crystal structure, translucency, color, and overall strength of the final product.

The Risk of Contamination

Sintering ovens must be impeccably clean. Even microscopic debris or cross-contamination from other materials (like coloring liquids) can cause significant discoloration, ruining the aesthetic outcome and forcing a complete remake.

Understanding the Trade-offs

Choosing zirconia is not a single decision; it is a series of compromises between competing priorities. Understanding these trade-offs is essential for clinical success.

Strength vs. Translucency

This is the primary trade-off. The strongest, most fracture-resistant zirconias are best suited for posterior bridges where forces are high, but they are also the most opaque. The most aesthetic, translucent zirconias are ideal for anterior teeth but are not recommended for long-span bridges.

Monolithic vs. Layered

A monolithic restoration is made from a single, solid block of zirconia. It is incredibly strong but can lack the natural depth of color found in a real tooth.

A layered restoration uses a zirconia core (substructure) with more aesthetic porcelain fused to the outside. This provides superior aesthetics but introduces a new failure point: the porcelain can chip off the underlying zirconia core.

Lab Precision vs. Clinical Forgiveness

Zirconia is a low-forgiveness material. Because it is so difficult to adjust chairside, the fit must be perfect from the laboratory. This places immense importance on the quality of the initial impression, the digital design, and the lab's validated milling and sintering workflow.

Making the Right Choice for Your Case

Your material selection must be dictated by the specific mechanical and aesthetic demands of the clinical situation.

- If your primary focus is maximum strength for posterior bridges: Choose a high-strength 3Y-TZP zirconia and accept the aesthetic compromise of higher opacity.

- If your primary focus is anterior aesthetics: Use a high-translucency 5Y-TZP zirconia for monolithic restorations or a layered zirconia restoration, understanding the trade-off in absolute strength.

- If your primary focus is predictable, reliable outcomes: Partner with a high-quality dental laboratory that can demonstrate a validated, repeatable, and meticulously controlled workflow for its zirconia production.

Ultimately, understanding that zirconia's limitations are inextricably linked to its processing is the key to successfully harnessing its remarkable clinical potential.

Summary Table:

| Aspect | High-Strength Zirconia (3Y-TZP) | High-Translucency Zirconia (5Y-TZP) |

|---|---|---|

| Primary Use | Posterior bridges, high-stress areas | Anterior crowns, aesthetic-focused cases |

| Key Strength | Excellent fracture resistance | Improved light transmission, natural look |

| Key Limitation | High opacity, difficult to blend | Reduced strength, not for long-span bridges |

| Processing Need | Precise, controlled sintering cycle | Precise, controlled sintering cycle |

Achieve predictable, high-quality zirconia restorations with KINTEK.

Zirconia's performance is critically dependent on precise laboratory processing, especially during the sintering stage. KINTEK specializes in providing the reliable lab equipment and consumables needed to ensure your zirconia restorations meet the highest standards of strength, fit, and aesthetics. Our products support dental laboratories in maintaining the meticulous control required for successful outcomes.

Let us help you master the zirconia process. Contact our experts today to discuss your laboratory's specific needs.

Visual Guide

Related Products

- Graphite Vacuum Furnace Negative Material Graphitization Furnace

- 1200℃ Muffle Furnace Oven for Laboratory

- Vacuum Heat Treat and Pressure Sintering Furnace for High Temperature Applications

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Horizontal High Temperature Graphite Vacuum Graphitization Furnace

People Also Ask

- What is the significance of using a tube furnace with vacuum-sealed quartz tubes? Master Ceramic Synthesis

- What are some positive and negative environmental effects of using biomass? A Balanced Look at a Renewable Energy Source

- What function does a high-temperature sintering furnace serve in biomass carbonization? Unlock Superior MFC Performance

- What would be an advantage of biomass over the use of coal? A Cleaner, Carbon-Neutral Energy Source

- What are the key differences between incineration and gasification? Explore Waste Management Solutions