While no single material can be declared the "most" biocompatible for every medical application, the clear industry consensus points to Titanium and its alloys as the gold standard for a vast range of permanent implants, particularly those requiring direct contact with bone and tissue. Its unique combination of strength, corrosion resistance, and ability to integrate with bone (osseointegration) makes it the benchmark against which other materials are often measured.

The critical insight is that biocompatibility is not an inherent property of a material, but a measure of how appropriately a material performs within a specific biological environment. The ideal choice is always dictated by the implant's function, its location in the body, and the desired host response.

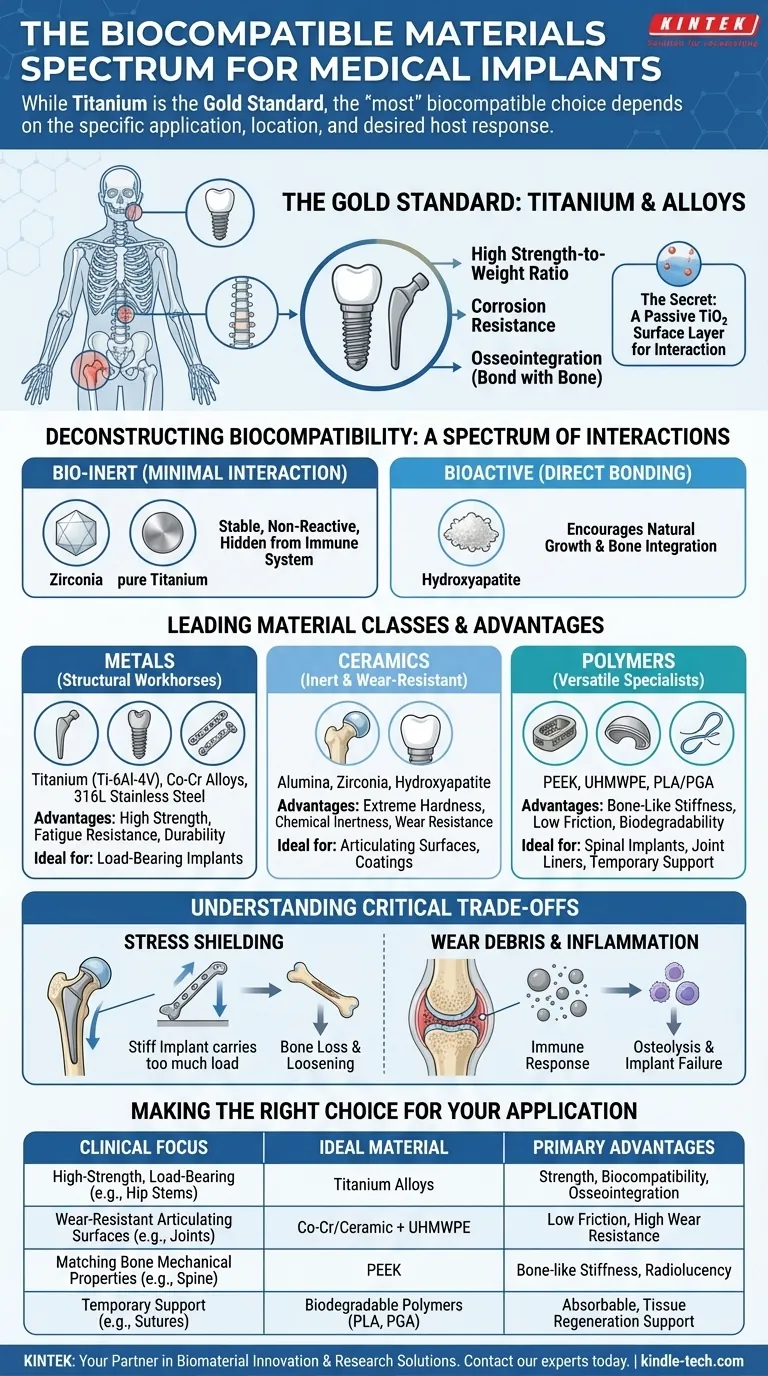

Deconstructing Biocompatibility: Beyond "Non-Toxic"

To select the right material, we must first understand that biocompatibility is a nuanced concept. It’s a spectrum of interactions between a material and the host's biological systems.

What Biocompatibility Truly Means

True biocompatibility means the material does not cause an unwanted local or systemic response. This includes being non-toxic, non-carcinogenic, and not triggering a significant inflammatory or allergic reaction over the long term.

The goal is a stable equilibrium between the implant and the surrounding tissue.

Bio-inert vs. Bioactive Materials

Materials interact with the body in different ways. Some are designed to be ignored, while others are designed to actively participate.

- Bio-inert materials, like Zirconia or pure Titanium, have minimal interaction with the body. They are designed to be stable, non-reactive, and essentially hidden from the immune system.

- Bioactive materials, like hydroxyapatite, are designed to bond directly with bone tissue, encouraging natural growth and creating a strong, integrated interface.

The Critical Role of the Surface

The body never "sees" the bulk material of an implant. It only interacts with the surface, often a layer of atoms that is completely different from the core.

For Titanium, the body interacts with a chemically stable, passive layer of titanium dioxide (TiO₂) that forms instantly when the metal is exposed to air or water. This oxide layer is the true source of its exceptional biocompatibility.

The Leading Classes of Biocompatible Materials

Implants are typically made from one of three primary material classes, each with its own set of advantages for specific functions.

Metals: The Structural Workhorses

Metals are used when high strength, fatigue resistance, and durability are required.

- Titanium (and Ti-6Al-4V alloy): The leader for orthopedic and dental implants. Its key advantages are its high strength-to-weight ratio and a stiffness (modulus of elasticity) that, while higher than bone, is much lower than other metals, reducing stress shielding.

- Cobalt-Chromium (Co-Cr) alloys: Valued for superior wear and corrosion resistance. They are commonly used for the articulating surfaces in hip and knee replacements.

- 316L Stainless Steel: A historically important biomaterial used for temporary devices like bone screws and plates. It is less expensive but has lower corrosion resistance and potential for nickel allergy reactions.

Ceramics: The Inert and Wear-Resistant Choice

Ceramics are exceptionally hard, chemically inert, and resistant to wear, making them ideal for specific high-performance applications.

- Alumina and Zirconia: These are extremely hard, bio-inert ceramics used for femoral heads in hip replacements and for dental crowns. Their smooth, durable surfaces minimize wear debris.

- Hydroxyapatite (HA): A bioactive calcium phosphate ceramic that is a primary mineral component of bone. It is often used as a coating on metal implants to promote faster and stronger bone integration.

Polymers: The Versatile Specialists

Polymers offer a wide range of properties, from high-strength plastics to absorbable materials that disappear over time.

- PEEK (Polyether Ether Ketone): A high-performance thermoplastic with excellent strength and a modulus of elasticity very close to that of human bone. This makes it a premier choice for spinal implants, as it minimizes stress shielding.

- UHMWPE (Ultra-High-Molecular-Weight Polyethylene): A durable polymer with a very low coefficient of friction. It is the standard material for the "cup" or socket liner in hip and knee joint replacements, articulating against a metal or ceramic head.

- Biodegradable Polymers (PLA, PGA): These materials are designed to degrade safely within the body after they have served their purpose, such as in sutures or scaffolds for tissue engineering.

Understanding the Critical Trade-offs

No material is perfect. The choice always involves balancing competing factors and potential failure modes.

Mechanical Mismatch and Stress Shielding

If an implant is significantly stiffer than the surrounding bone (like steel), it carries too much of the mechanical load. This "shields" the bone from the normal stresses it needs to stay healthy, potentially leading to bone loss and implant loosening over time.

Corrosion and Ion Leaching

All metals, to some degree, release metallic ions into the body as they corrode. While Titanium is highly resistant, concerns exist for materials like Co-Cr alloys or stainless steel, as these ions can sometimes cause adverse tissue reactions.

Wear Debris and Inflammatory Response

In articulating joints, the rubbing of surfaces can generate microscopic wear particles. The body's immune system may attack these particles, leading to a chronic inflammatory response that can destroy bone tissue (osteolysis) and cause the implant to fail.

Making the Right Choice for Your Application

The optimal material is the one whose properties best solve the specific clinical problem.

- If your primary focus is high-strength, load-bearing applications (e.g., hip stems, dental roots): Titanium alloys are the default choice due to their excellent strength, biocompatibility, and proven ability to osseointegrate.

- If your primary focus is wear-resistant articulating surfaces (e.g., joint replacements): A combination of a Cobalt-Chromium or Ceramic femoral head articulating against an UHMWPE cup is the industry standard.

- If your primary focus is matching the mechanical properties of bone to avoid stress shielding (e.g., spinal cages): PEEK is the leading candidate due to its bone-like stiffness and radiolucency (visibility on X-rays).

- If your primary focus is temporary support for tissue regeneration (e.g., absorbable sutures, tissue scaffolds): Biodegradable polymers like PLA and PGA are specifically designed for this purpose.

Ultimately, material selection is a precise engineering decision that matches the unique challenges of the human body with a material best suited to succeed for decades.

Summary Table:

| Material Class | Key Examples | Primary Advantages | Ideal Applications |

|---|---|---|---|

| Metals | Titanium & Alloys | High strength, osseointegration, corrosion resistance | Orthopedic & dental implants (hip stems, dental roots) |

| Ceramics | Alumina, Zirconia, Hydroxyapatite | Extreme hardness, wear resistance, bio-inert/bioactive | Femoral heads in hip replacements, dental crowns |

| Polymers | PEEK, UHMWPE, PLA/PGA | Bone-like stiffness, low friction, biodegradability | Spinal implants, joint liners, absorbable sutures |

Ready to select the perfect material for your next medical implant project?

KINTEK specializes in providing high-quality laboratory equipment and consumables essential for the research, development, and testing of biocompatible materials. Whether you are working with Titanium alloys, advanced polymers like PEEK, or specialized ceramics, our solutions support precision and reliability at every stage.

Let us help you achieve superior outcomes. Contact our experts today to discuss your specific laboratory needs and discover how KINTEK can be your trusted partner in innovation.

Visual Guide

Related Products

- Custom PTFE Teflon Parts Manufacturer for PTFE Containers

- Laboratory CVD Boron Doped Diamond Materials

- Custom PTFE Teflon Parts Manufacturer for Hollow Etching Flower Basket ITO FTO Developing Glue Removal

- Electrode Polishing Material for Electrochemical Experiments

- Conductive Carbon Cloth Carbon Paper Carbon Felt for Electrodes and Batteries

People Also Ask

- Why are PTFE containers necessary for selective HF etching of MAX phases? Ensure Safe & Pure MXene Synthesis

- Why is a PTFE container with a metal base necessary for the directional freezing process of honeycomb lignin foam?

- Why are polytetrafluoroethylene (PTFE) containers essential for assessing the corrosion resistance of glassified waste?

- How should a PTFE cleaning basket be cleaned and dried after use? Ensure Purity and Prevent Cross-Contamination

- What is the difference between PPF and coating? Armor vs. Slick Shell for Your Car