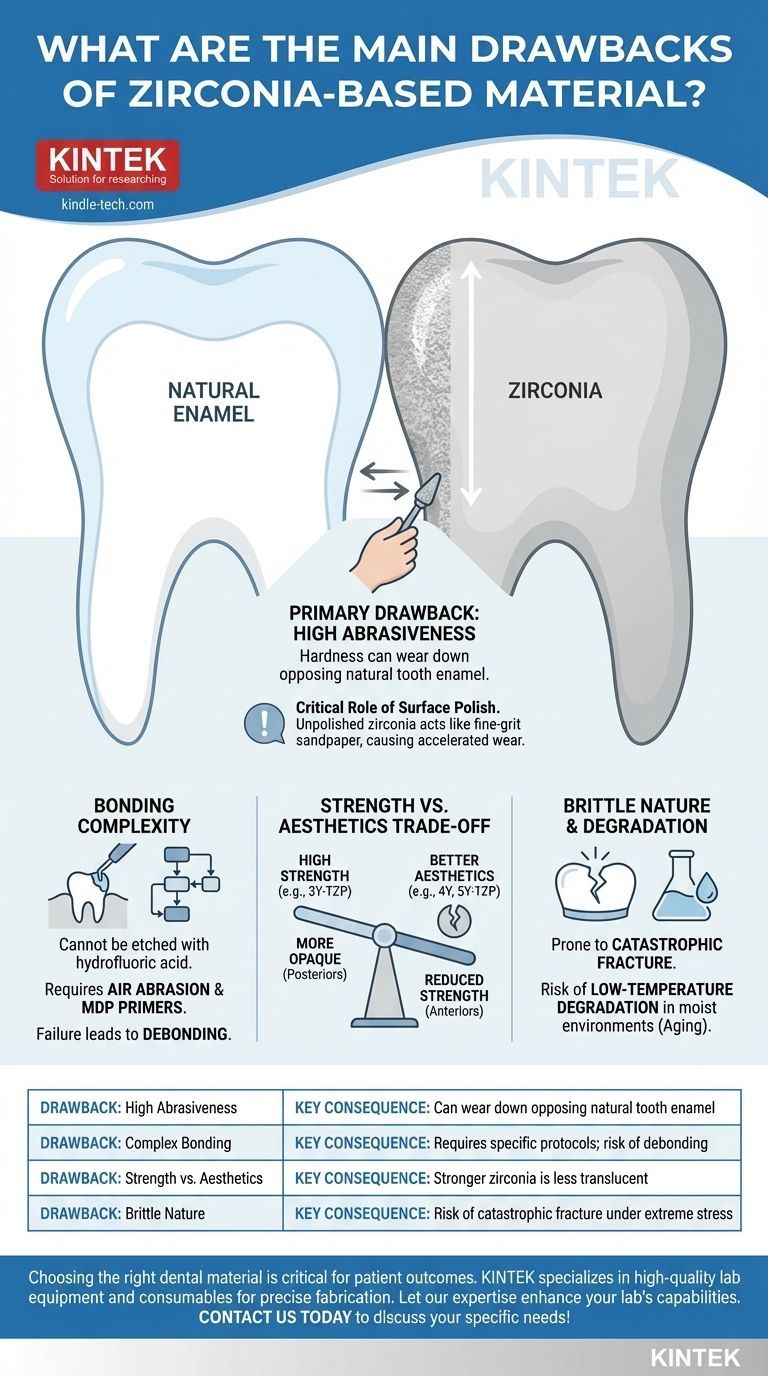

While zirconia is prized for its exceptional strength and biocompatibility, its most significant drawback is a direct consequence of this strength: its hardness. This property creates a high potential for zirconia to wear down and damage the natural teeth it bites against, especially if its surface is not perfectly polished.

The core challenge with zirconia is not its own risk of failure, but the potential harm it can cause to opposing tooth structures. This, combined with complex bonding procedures and a fundamental trade-off between strength and aesthetics, defines its primary limitations.

The Abrasiveness Paradox: Strength vs. Enamel

The very characteristic that makes zirconia so durable—its extreme hardness—is also the source of its most significant clinical concern.

The Hardness Factor

Zirconia is substantially harder than natural tooth enamel. When two materials of unequal hardness grind against each other, the softer material will always wear away.

The Critical Role of Surface Polish

A properly fabricated and polished zirconia restoration has a very smooth, low-friction surface that is kind to opposing teeth. However, if a dentist needs to adjust the bite and does not meticulously re-polish the surface, it becomes incredibly abrasive, acting like fine-grit sandpaper on the opposing enamel.

The Clinical Consequence

This accelerated wear can lead to the loss of healthy tooth structure on the opposing teeth, potentially causing sensitivity, changes in bite, and the need for further dental work.

The Challenge of Adhesion and Adjustments

Working with zirconia is less straightforward than with many traditional dental materials, presenting challenges both in the lab and in the clinic.

Bonding Complexity

Unlike glass-ceramics, zirconia cannot be etched with hydrofluoric acid, the gold standard for creating a strong adhesive bond. Bonding zirconia reliably requires a multi-step protocol involving air abrasion (sandblasting) and the use of special chemical primers containing MDP to achieve a durable bond. Failure to follow this protocol can lead to the restoration debonding, or falling off.

Difficulty of Intraoral Modification

Adjusting a zirconia crown or bridge in the patient's mouth is difficult due to its hardness. It requires specific diamond burs, and as mentioned, creates an urgent need for careful re-polishing to prevent it from becoming abrasive.

Understanding the Trade-offs

Choosing zirconia involves navigating a series of compromises, most notably between its mechanical properties and its visual appearance.

The Strength vs. Aesthetics Compromise

The strongest forms of zirconia (like 3Y-TZP) are also the most opaque. This gives them a chalky, less-lifelike appearance, making them suitable for back teeth (posteriors) but a poor choice for highly visible front teeth (anteriors).

Newer formulations (4Y and 5Y-TZP, often marketed as "anterior zirconia") are much more translucent and aesthetically pleasing. However, this is achieved by altering the crystal structure, which inherently reduces the material's flexural strength and fracture toughness.

Risk of Catastrophic Failure

Like all ceramics, zirconia is a brittle material. It does not bend or deform under pressure; it breaks. While its high strength makes fracture rare, if a failure does occur, it is often a complete, catastrophic fracture of the restoration rather than a small chip.

Potential for Low-Temperature Degradation

Over long periods in a moist environment (like the mouth), zirconia can undergo a slow process called low-temperature degradation or "aging." This involves a gradual change in its crystal structure that can reduce its strength over time. While modern formulations have significantly minimized this risk, it remains an inherent property of the material.

Making the Right Choice for Your Goal

Understanding these drawbacks is key to using zirconia effectively. The decision should be based on the specific clinical goal.

- If your primary focus is maximum durability for back teeth: High-strength zirconia is an excellent choice, but only if the clinician commits to meticulous bite adjustment and polishing to protect opposing teeth.

- If your primary focus is aesthetics for front teeth: A more translucent zirconia is a good option, but you must accept a lower strength profile compared to its posterior counterpart or consider alternative materials like lithium disilicate.

- If the bond is critical for retention: You must ensure the correct, complex bonding protocol is used, as traditional cementing methods offer significantly weaker results.

Ultimately, leveraging zirconia's immense strength while mitigating its inherent risks is the key to achieving successful and lasting outcomes.

Summary Table:

| Drawback | Key Consequence |

|---|---|

| High Abrasiveness | Can wear down opposing natural tooth enamel |

| Complex Bonding | Requires specific protocols; risk of debonding |

| Strength vs. Aesthetics | Stronger zirconia is less translucent |

| Brittle Nature | Risk of catastrophic fracture under extreme stress |

Choosing the right dental material is critical for patient outcomes. KINTEK specializes in high-quality lab equipment and consumables for dental laboratories. Our products support the precise fabrication and finishing of zirconia restorations, helping you mitigate its drawbacks and achieve durable, aesthetic results. Let our expertise enhance your lab's capabilities. Contact us today to discuss your specific needs!

Visual Guide

Related Products

- Dental Porcelain Zirconia Sintering Ceramic Furnace Chairside with Transformer

- Vacuum Dental Porcelain Sintering Furnace

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- What temperature can silicon carbide withstand? Operating Limits from 1600°C to 2700°C

- What are the classification of ceramic materials? A Guide to Oxides, Non-Oxides, and Composites

- What industry uses ceramics? Discover the Critical Role of Advanced Ceramics in Modern Technology

- What is the primary function of porous ceramic supports? Ensuring Structural Integrity in Zeolite Membranes

- What role does polyurethane foam play as a sacrificial template? Create Advanced Porous MgO Ceramics

- Why is pre-heating LLZO ceramic powder recommended? Optimize Interfaces for High-Performance Polymer Composites

- Does sintering increase hardness? Master the Process for Superior Material Strength

- What is the thermal expansion of SiC? Master Its Low CTE for Superior High-Temp Performance