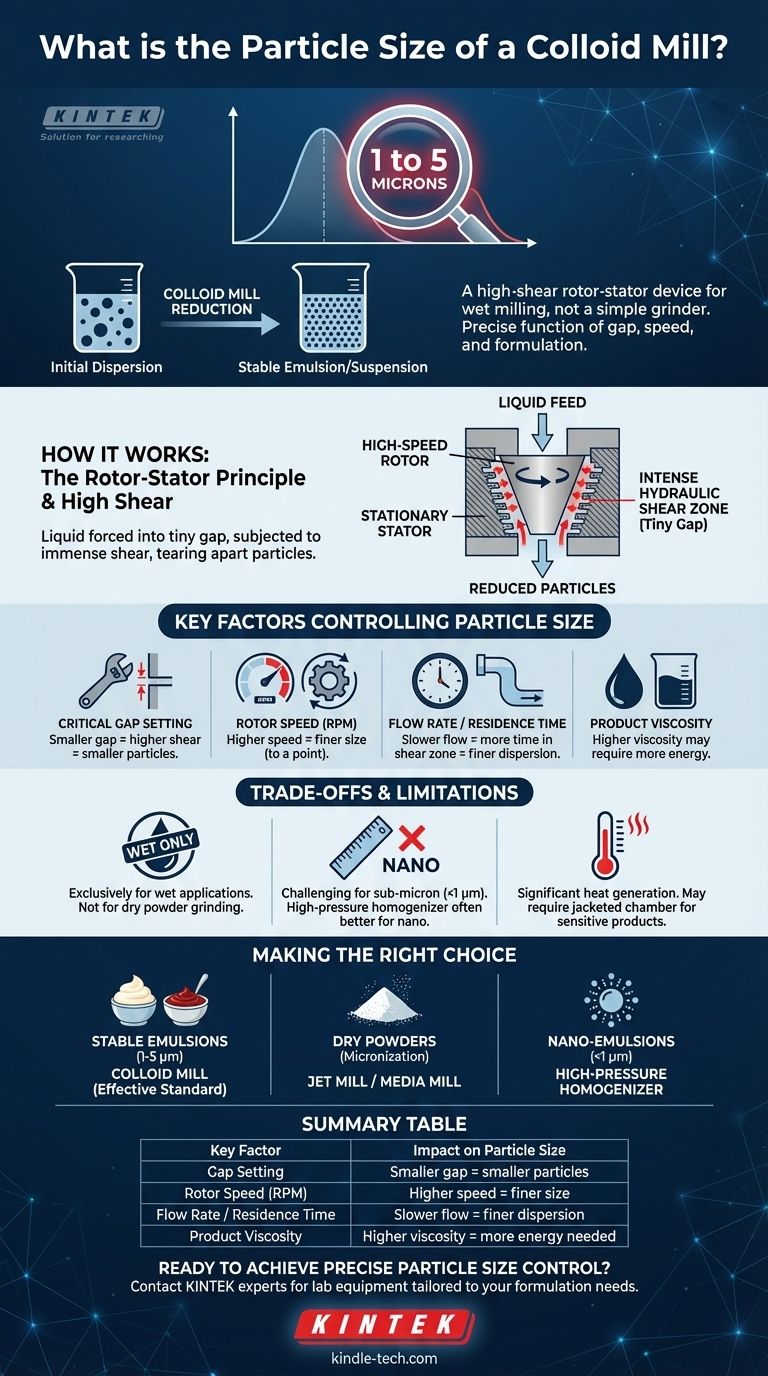

In a properly configured colloid mill, you can expect to achieve a particle or droplet size distribution typically in the range of 1 to 5 microns. This technology excels at reducing the size of particles or droplets already dispersed within a liquid to create stable emulsions and suspensions.

A colloid mill is not a simple grinder; it is a high-shear rotor-stator device designed for wet milling applications. The final particle size is less about brute force and more a precise function of the gap setting, rotor speed, and the formulation of your product.

How a Colloid Mill Achieves Particle Reduction

A colloid mill operates on a simple but effective mechanical principle to create extremely high shear forces. Understanding this mechanism is key to controlling the outcome.

The Rotor-Stator Principle

The core of the machine consists of a high-speed rotor that spins with very close proximity to a stationary stator. Both the rotor and stator are typically conical and feature intricate patterns of grooves and channels.

The Role of High Shear

As the liquid product is fed into the mill, it is forced into the tiny gap between the spinning rotor and the fixed stator. The intense velocity difference in this gap subjects the material to immense hydraulic shear, which tears apart and reduces the size of suspended particles or liquid droplets.

Key Factors Controlling Final Particle Size

Achieving your target particle size is not automatic. It requires careful control over several operational variables.

The Critical Gap Setting

The most influential factor is the adjustable gap between the rotor and stator. A smaller gap (measured in thousandths of an inch) creates higher shear forces and results in smaller particles.

Rotor Speed (RPM)

The rotational speed of the rotor directly impacts the amount of shear energy applied to the product. Higher speeds generally lead to finer particle sizes, though there is a point of diminishing returns.

Residence Time and Flow Rate

The amount of time the product spends within the high-shear zone is critical. A slower flow rate increases the residence time, allowing each portion of the product to receive more energy, typically resulting in a finer dispersion.

Product Viscosity and Formulation

The physical properties of your liquid base and the presence of stabilizers (surfactants) play a significant role. Higher viscosity products may require more energy to achieve the same particle size reduction.

Understanding the Trade-offs and Limitations

While powerful, a colloid mill is a specialized tool with specific strengths and weaknesses. It is not the correct solution for every particle reduction task.

Designed for Wet Milling Only

A colloid mill is exclusively for wet applications where solid particles or immiscible liquids are already suspended in a liquid carrier. It cannot be used for dry powder grinding.

Sub-Micron Challenges

While a colloid mill can approach 1 micron, producing particles consistently well below this size (in the nanometer range) is difficult. For true nano-emulsions, a high-pressure homogenizer is often a more effective technology.

Significant Heat Generation

The intense shear energy is converted into heat. For temperature-sensitive products like certain pharmaceuticals or food emulsions, this heat generation must be managed, often with a jacketed milling chamber.

Making the Right Choice for Your Application

Selecting the correct milling technology requires a clear understanding of your starting material and final product goals.

- If your primary focus is creating stable emulsions or dispersions (like sauces, creams, or inks) in the 1-5 micron range: A colloid mill is a highly effective and standard piece of equipment for this task.

- If your primary focus is grinding dry powders into fine particles (micronization): You should investigate a completely different technology, such as a jet mill or a media mill.

- If your primary focus is producing nano-emulsions or dispersions consistently below 1 micron: A high-pressure homogenizer is the more appropriate and powerful technology for the job.

Ultimately, choosing the right equipment begins with a clear definition of your target particle size and processing requirements.

Summary Table:

| Key Factor | Impact on Particle Size |

|---|---|

| Gap Setting | Smaller gap = higher shear = smaller particles |

| Rotor Speed (RPM) | Higher speed = finer particle size |

| Flow Rate / Residence Time | Slower flow = more time in shear zone = finer dispersion |

| Product Viscosity | Higher viscosity may require more energy for size reduction |

Ready to achieve precise particle size control for your emulsions or dispersions? The experts at KINTEK are here to help. We specialize in lab equipment and consumables, providing colloid mills and other high-shear technologies tailored to your formulation needs—whether you're developing pharmaceuticals, food products, or specialty chemicals. Contact our team today to discuss your application and discover the ideal solution for your laboratory.

Visual Guide

Related Products

- Laboratory Test Sieves and Sieving Machines

- Laboratory Single Horizontal Jar Mill

- High Energy Planetary Ball Mill Milling Machine for Laboratory

- High Energy Planetary Ball Mill Milling Machine for Laboratory

- High-Energy Omnidirectional Planetary Ball Mill Milling Machine for Laboratory

People Also Ask

- What are the different types of pulverization? Match the Method to Your Material and Goal

- What is a mixer used in a laboratory? A Guide to Vortex Mixers vs. Mixer Mills

- What is the principle of a roller mill? Achieve Precise Grinding and Dispersion for Your Materials

- How does a Vibratory Mill improve niobium recovery efficiency? Optimize Waste Pre-treatment for Maximum Yield

- What is the role of a V-type mixer in the preparation of Ti-Cr3C2 composite powders? Ensuring Macroscopic Uniformity

- How do industrial crushing and grinding systems optimize antimony ore separation? Achieve Maximum Mineral Liberation

- How do grinding systems and HGI testing guide torrefied biomass processing? Optimize Your Energy Efficiency

- What is the function of an agate mortar and pestle in solid-state battery preparation? Ensure High Purity Mixing