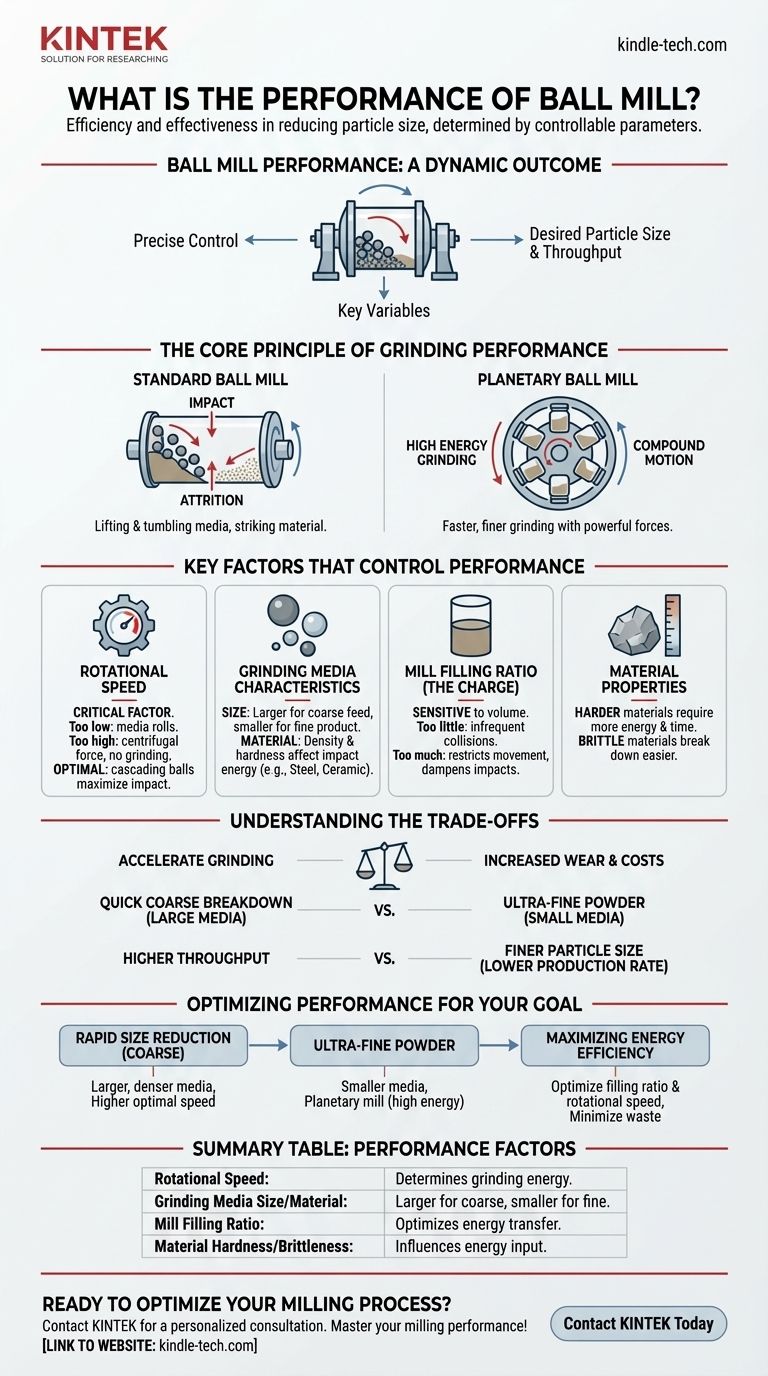

The performance of a ball mill is not a single metric but rather its efficiency and effectiveness in reducing the particle size of a given material. This performance is determined by a combination of controllable operational parameters, including the mill's rotational speed, the characteristics of the grinding media, the volume of material inside, and the type of mill being used.

The central takeaway is that ball mill performance is not a fixed attribute of the machine itself. It is a dynamic outcome that you can precisely control by understanding and manipulating a few key variables to achieve your desired particle size and throughput.

The Core Principle of Grinding Performance

A ball mill's effectiveness is rooted in a simple mechanical principle: transferring kinetic energy from moving balls to the material being processed. The efficiency of this energy transfer dictates the overall performance.

How a Standard Ball mill Works

In a standard horizontal or tumbling ball mill, the cylinder rotates, lifting the grinding media (steel or ceramic balls). The media then tumbles and cascades down, striking the material. This action grinds the material through two primary forces: impact (from falling balls) and attrition (from balls rubbing against each other and the material).

How a Planetary Ball Mill Achieves High Energy

Planetary ball mills generate significantly higher energy for more rapid and finer grinding. They consist of grinding jars mounted on a "sun wheel." As the main wheel rotates in one direction, the jars rotate on their own axes in the opposite direction. This compound motion creates powerful forces, causing the balls to collide with the material at much higher speeds and energies than in a standard mill.

Key Factors That Control Performance

To optimize a ball mill, you must understand the levers you can pull. Each factor has a direct impact on the final product.

Rotational Speed

The speed of the cylinder's rotation is the most critical factor. If the speed is too low, the balls will simply roll down the side of the mill, providing very little grinding action. If the speed is too high (known as the "critical speed"), centrifugal force will pin the balls to the mill's outer wall, resulting in no grinding at all. Optimal performance is achieved at a speed that allows the balls to cascade freely, maximizing impact.

Grinding Media Characteristics

The balls themselves are a crucial variable. Their size matters; larger balls are effective at breaking down coarse feed materials, while smaller balls are better for producing a fine finished product by filling the void spaces. The material of the media (e.g., steel, ceramic) determines its density and hardness, which in turn affects the impact energy it can deliver.

Mill Filling Ratio (The "Charge")

The performance is highly sensitive to the volume of grinding media within the mill. This is often referred to as the filling ratio or charge. Too little media results in infrequent collisions and inefficient grinding. Too much media restricts movement, dampens impacts, and reduces the space available for the material, again lowering performance.

Material Properties

Finally, the characteristics of the material you are grinding play a significant role. Harder, more durable materials will naturally require more energy and longer grinding times to break down compared to softer or more brittle materials.

Understanding the Trade-offs

Optimizing ball mill performance always involves balancing competing factors. There is rarely a single "best" setting, only the best setting for a specific goal.

Speed vs. Wear

Increasing rotational speed (up to the optimal point) will accelerate the grinding process. However, this also increases the rate of wear on both the grinding media and the inner lining of the mill, leading to higher operational costs and more frequent maintenance.

Media Size vs. Final Product

Using large, heavy media is excellent for quickly breaking down large particles. However, these same large balls are inefficient at producing an ultra-fine powder. Achieving a very fine grind often requires smaller media, which in turn is less effective on very coarse input materials.

Throughput vs. Fineness

There is a direct trade-off between how much material you can process (throughput) and how fine you can grind it. Achieving a finer particle size requires more time and energy per unit of material, which inherently lowers the overall rate of production.

Optimizing Performance for Your Goal

Your ideal settings will depend entirely on the outcome you need to achieve. Use these principles as your guide.

- If your primary focus is rapid size reduction of coarse material: Use larger, denser grinding media and operate at the higher end of the optimal speed range to maximize impact force.

- If your primary focus is producing an ultra-fine powder: Use smaller grinding media to increase the number of contact points and consider a planetary ball mill for its higher energy input.

- If your primary focus is maximizing energy efficiency: Carefully test and optimize the mill's filling ratio and rotational speed to ensure energy is being used for grinding, not wasted on ineffective media movement.

Ultimately, mastering your ball mill's performance comes from understanding that you are in direct control of the grinding environment.

Summary Table:

| Key Performance Factor | Impact on Grinding Result |

|---|---|

| Rotational Speed | Determines grinding energy; too low or high reduces efficiency. |

| Grinding Media Size/Material | Larger media for coarse grinding; smaller for fine powders. |

| Mill Filling Ratio | Optimizes energy transfer; critical for throughput and fineness. |

| Material Hardness/Brittleness | Influences required energy input and grinding time. |

Ready to Optimize Your Milling Process?

Understanding the variables is the first step; applying them with the right equipment is the key to success. Whether you need a standard tumbling ball mill for robust size reduction or a high-energy planetary ball mill for nano-level grinding, KINTEK has the solution.

Our experts will help you select the ideal mill and grinding media to achieve your specific particle size and throughput goals, maximizing your lab's productivity and efficiency.

Contact KINTEL today for a personalized consultation and let us help you master your milling performance!

Visual Guide

Related Products

- Stainless Steel Laboratory Ball Mill for Dry Powder and Liquid with Ceramic Polyurethane Lining

- Laboratory Ball Mill Jar Mill with Metal Alloy Grinding Jar and Balls

- Laboratory Four-Body Horizontal Jar Mill

- Laboratory Single Horizontal Jar Mill

- High-Energy Omnidirectional Planetary Ball Mill Milling Machine for Laboratory

People Also Ask

- What is the function of ball milling in Se–Li3PS4–C composite cathodes? Optimize All-Solid-State Battery Performance

- What role do planetary ball mills play in cathode slurry preparation? Optimize LiFePO4 & NCM622 Performance

- What are the different modes of a ball mill? Master the 3 Key Operating Modes for Optimal Grinding

- What are the factors affecting ball mill performance? Optimize Speed, Media, and Material for Efficiency

- What is the function of a high-energy vibrating ball mill? Transform Mg-Y-Cu Into Superior Metallic Glass Powders

- What role does a planetary ball mill play in the synthesis of Li2S-P2S5-SeS2? Powering Solid-State Electrolytes

- What is the role of a planetary ball mill in the synthesis of Li2S–P2S5 sulfide solid-state electrolytes?

- How is a high-energy ball mill utilized in the dry-process preparation of composite electrolytes? | KINTEK