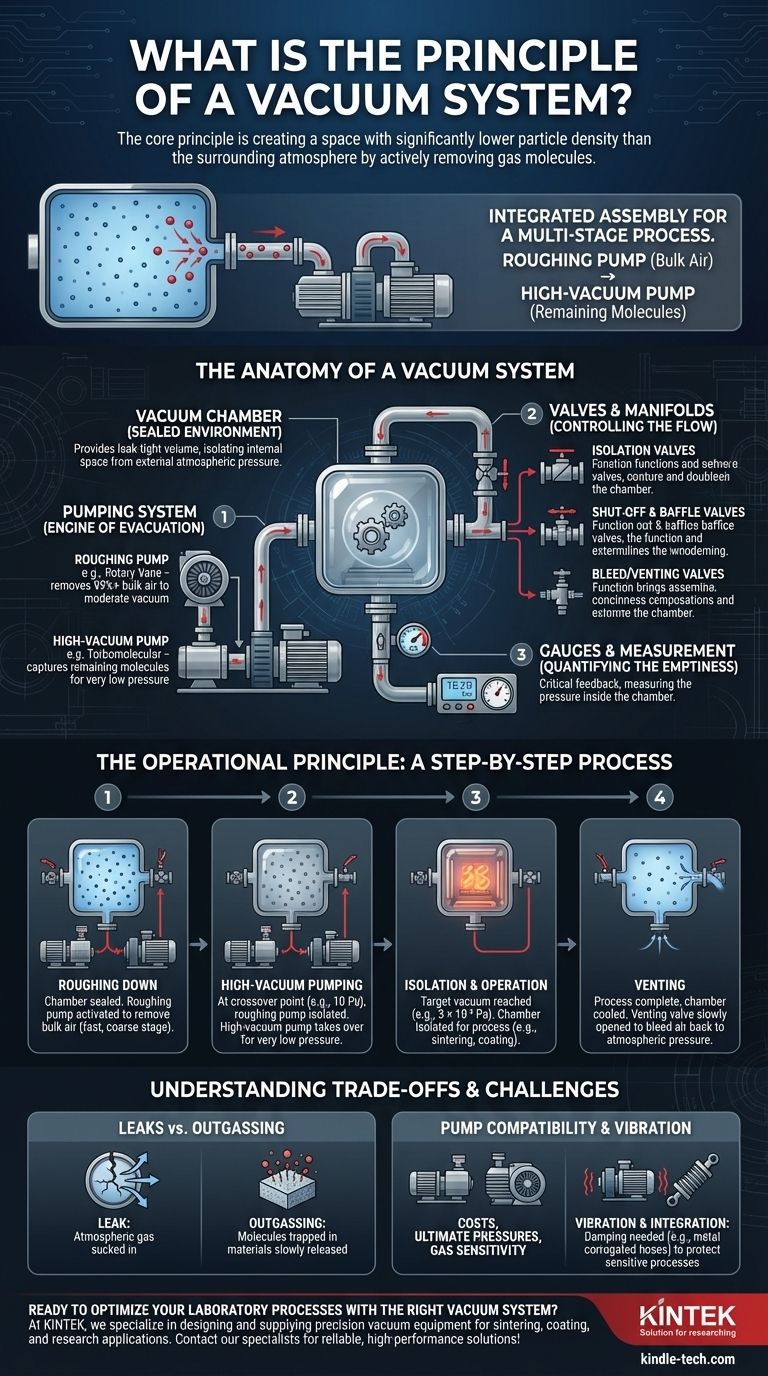

The core principle of a vacuum system is to create a space with significantly lower particle density than the surrounding atmosphere by actively removing gas molecules from a sealed chamber. This is not achieved by a single component, but through a coordinated system of pumps, valves, and gauges that work in a specific sequence to evacuate, measure, and maintain this low-pressure environment.

A vacuum system is best understood not as a single device, but as an integrated assembly designed for a multi-stage process. The fundamental principle involves using a "roughing" pump to remove bulk air, followed by a "high-vacuum" pump to capture remaining molecules, all while valves control the flow and gauges measure the result.

The Anatomy of a Vacuum System

A vacuum system is composed of several critical parts that must work in harmony. Understanding the role of each component is key to understanding the overall principle.

The Vacuum Chamber (The Sealed Environment)

The process begins with the vacuum chamber or vessel. This is the sealed container where the low-pressure environment is created.

Its sole purpose is to provide a leak-tight volume, isolating the internal space from the external atmospheric pressure. All operations, such as sintering or coating, occur within this chamber.

The Pumping System (The Engine of Evacuation)

Pumps are the heart of the system, responsible for removing gas molecules. Systems typically use at least two types of pumps in series for efficiency.

Roughing Pumps, such as mechanical or direct pumps, handle the initial stage. They remove the vast majority (over 99%) of the air, taking the chamber from atmospheric pressure down to a moderate vacuum.

High-Vacuum Pumps, such as turbomolecular or diffusion pumps, take over after the roughing pump. These pumps cannot operate at atmospheric pressure and are designed to capture the few remaining individual gas molecules to achieve very low pressures.

Valves and Manifolds (Controlling the Flow)

Valves are the gatekeepers of the system, directing the flow of gas and isolating components. Without them, a system would be uncontrollable.

Isolation Valves separate the pumps from the chamber, allowing the chamber to remain under vacuum even when the pumps are serviced.

Shut-off and Baffle Valves control the sequence of pumping, ensuring the high-vacuum pump is only exposed to pressure it can handle.

Bleed or Venting Valves are used to safely and slowly reintroduce air into the chamber, bringing it back to atmospheric pressure so you can open the door and remove your workpiece.

Gauges and Measurement (Quantifying the Emptiness)

You cannot control what you cannot measure. Vacuum gauges provide the critical feedback needed to operate the system.

These devices measure the pressure, or lack thereof, inside the chamber. Different gauges are required for different pressure ranges, from rough vacuum to high vacuum, often represented in units like Pascals (Pa) or Torr.

The Operational Principle: A Step-by-Step Process

Creating a vacuum is a sequential process that leverages the different components in a specific order.

Stage 1: Roughing Down

First, the chamber door is sealed. The roughing pump is activated to remove the bulk of the air from the chamber and the connected piping. This is a fast but coarse stage of evacuation.

Stage 2: High-Vacuum Pumping

Once the pressure reaches a certain crossover point (e.g., around 10 Pa), the roughing pump is valved off from the main chamber. The high-vacuum valve is then opened, and the high-vacuum pump begins to capture the remaining stray molecules. The roughing pump often continues to run, serving as a "backing pump" for the high-vacuum pump.

Stage 3: Isolation and Operation

When the target vacuum level is reached (e.g., 3 × 10⁻³ Pa for sintering), the high-vacuum valve can be closed to isolate the chamber. The process, like heating a material to its sintering temperature, can now proceed in the stable, controlled vacuum environment.

Stage 4: Venting

After the process is complete and the chamber has cooled, the venting valve is slowly opened. This carefully bleeds air back into the chamber, equalizing the pressure with the outside atmosphere and allowing the door to be safely opened.

Understanding the Trade-offs and Challenges

While powerful, vacuum systems are not without their complexities. Success depends on navigating several key challenges.

Leaks vs. Outgassing

The primary enemy of any vacuum system is a leak, where atmospheric gas gets sucked into the chamber through a faulty seal or crack, preventing the system from reaching its target pressure.

A second, more subtle challenge is outgassing, where molecules trapped within the materials inside the chamber (including the workpiece itself) are slowly released under vacuum, adding to the gas load the pumps must remove.

Pump Compatibility

The choice of high-vacuum pump (e.g., turbomolecular vs. diffusion) is a critical decision. Each has different costs, maintenance requirements, ultimate pressures, and sensitivities to certain types of gases. The wrong pump can contaminate a process or fail prematurely.

Vibration and System Integration

Pumps, especially large mechanical ones, generate vibration. As noted in technical designs, components like metal corrugated hoses are often used to connect pumps to the chamber, damping vibrations that could otherwise disrupt sensitive processes or damage connections.

Making the Right Choice for Your Goal

The design and operation of a vacuum system are dictated entirely by its intended application.

- If your primary focus is industrial processing (like sintering or coating): Your priority is a robust, reliable system with automated valve control and pumps chosen for process compatibility and high throughput.

- If your primary focus is scientific research: You need a flexible system with highly precise measurement gauges and potentially interchangeable pumps to accommodate a wide range of experimental needs.

- If your primary focus is basic lab work or degassing: A simpler setup with just a mechanical "roughing" pump and a manual valve system may be sufficient for reaching the necessary moderate vacuum level.

Understanding these core principles transforms a vacuum system from a complex machine into a predictable and powerful tool for achieving your objective.

Summary Table:

| Component | Function | Key Examples |

|---|---|---|

| Vacuum Chamber | Provides sealed, leak-tight environment for processes | Sintering furnace, coating chamber |

| Roughing Pump | Removes bulk air (99%+) from atmospheric to moderate vacuum | Rotary vane pumps, scroll pumps |

| High-Vacuum Pump | Captures remaining molecules for very low pressures | Turbomolecular pumps, diffusion pumps |

| Valves & Manifolds | Controls gas flow and isolates system components | Isolation valves, venting valves |

| Vacuum Gauges | Measures pressure in different ranges (Pa, Torr) | Pirani gauges, capacitance manometers |

Ready to optimize your laboratory processes with the right vacuum system?

At KINTEK, we specialize in designing and supplying precision vacuum equipment for sintering, coating, and research applications. Whether you need a robust industrial system or a flexible research setup, our experts will help you select the perfect configuration for your specific requirements.

Contact our vacuum specialists today to discuss how we can enhance your lab's capabilities with reliable, high-performance vacuum solutions!

Visual Guide

Related Products

- Circulating Water Vacuum Pump for Laboratory and Industrial Use

- Oil Free Diaphragm Vacuum Pump for Laboratory and Industrial Use

- Laboratory Rotary Vane Vacuum Pump for Lab Use

- Vacuum Hot Press Furnace Machine Heated Vacuum Press

- Electric Heated Hydraulic Vacuum Heat Press for Lab

People Also Ask

- What are the advantages of a water circulating vacuum pump? Superior Durability for Demanding Lab Environments

- How does a water circulating vacuum pump operate? Discover the Efficient Liquid Piston Principle

- What is the importance of a vacuum pump for Schottky hybrid interfaces? Achieve Atomic-Level Purity and Bonding

- What types of gases can a water circulating vacuum pump handle? Safely Manage Flammable, Condensable & Dirty Gases

- What determines the vacuum degree achievable by a water circulating vacuum pump? Unlock the Physics of Its Limits