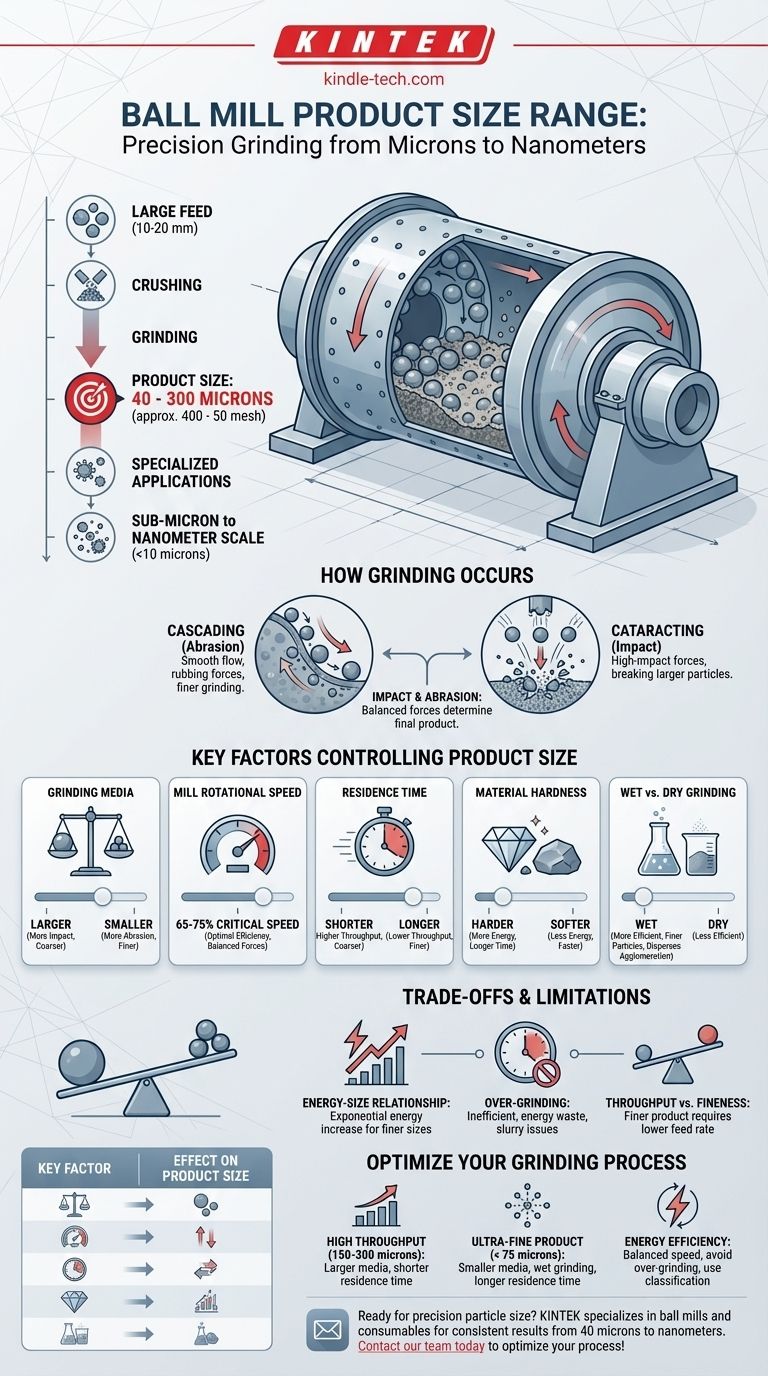

In material processing, a ball mill is a fine grinding machine that typically reduces material down to a product size range of 40 to 300 microns (approximately 400 to 50 mesh). For specialized applications, particularly with wet grinding and optimized media, ball mills can achieve sizes well below 10 microns, entering the sub-micron or even nanometer scale.

The final product size from a ball mill is not a fixed number but a highly controllable output. It is determined by the interplay between the grinding media, the properties of the material being ground, and the mill's operational parameters.

The Mechanics of Particle Reduction

A ball mill is a hollow cylinder that rotates on its axis, partially filled with grinding media like steel or ceramic balls. As the mill turns, the media is lifted up the side of the shell and then tumbles back down, crushing and grinding the material trapped between the balls.

How Grinding Occurs

The tumbling motion of the media creates two primary grinding forces. Cascading is when the balls tumble over each other in a smooth flow, creating abrasive forces that grind particles. Cataracting is when the balls are thrown from near the top of the shell, creating high-impact forces that shatter particles.

The Two Grinding Forces

Impact is the dominant force for breaking down larger feed particles. Abrasion (or attrition) is the rubbing action that grinds particles down to a very fine size. The balance between these two forces is key to controlling the final product.

The Importance of Proper Feed Size

A ball mill is a fine grinder, not a primary crusher. It operates most efficiently with a pre-crushed feed, typically with a top size of less than 10-20 millimeters. Feeding oversized material to a ball mill leads to inefficiency and excessive wear.

Key Factors Controlling Final Product Size

You can adjust several variables to precisely control the fineness of the output product. Understanding these levers is critical for process optimization.

Grinding Media Characteristics

The size, density, and material of the grinding balls are crucial. Smaller media provides more surface area and contact points, resulting in a finer product size through increased abrasion. Larger, denser media increases the impact force, which is better for coarser feed.

Mill Rotational Speed

Mill speed is expressed as a percentage of "critical speed"—the speed at which the media would centrifuge and stick to the mill's inner wall. Most mills operate at 65-75% of critical speed to achieve the optimal balance of cascading and cataracting for efficient grinding.

Residence Time

This is the amount of time the material spends inside the mill. A longer residence time naturally results in a finer grind, as the particles are subjected to more impact and abrasion events. This is a direct trade-off with the mill's throughput (tons per hour).

Material Hardness and Friability

The intrinsic properties of the material being ground have a significant effect. Harder, less friable materials (like quartz) require more energy and time to break down compared to softer materials (like limestone).

Wet vs. Dry Grinding

Grinding can be done dry or in a slurry (wet). Wet grinding is generally more efficient, consumes less energy per ton, and can produce finer particles. The liquid helps disperse the particles, preventing cushioning and agglomeration.

Understanding the Trade-offs and Limitations

While powerful, a ball mill is not a universal solution. Its operation involves fundamental trade-offs that impact efficiency and cost.

The Energy-Size Relationship

Reducing particle size is an energy-intensive process. The energy required to achieve a certain fineness increases exponentially as the target particle size decreases. Grinding from 100 microns down to 20 microns requires far more energy than grinding from 500 to 100.

The Problem of Over-Grinding

Leaving material in the mill for too long is inefficient. It wastes energy creating ultra-fine particles that may not be necessary for the process and can even cause issues like slurry thickening or particle agglomeration.

Throughput vs. Fineness

This is the most common operational trade-off. Achieving a finer product size almost always requires reducing the feed rate, which lowers the overall plant throughput.

How to Apply This to Your Goal

Your optimal ball mill setup depends entirely on your final objective. Consider these guiding principles to match the machine's parameters to your process needs.

- If your primary focus is high throughput for a moderate product (150-300 microns): Use larger grinding media to maximize impact forces and operate with a shorter residence time to increase the feed rate.

- If your primary focus is an ultra-fine product (< 75 microns): Prioritize smaller grinding media, consider wet grinding to improve efficiency, and accept that a longer residence time and lower throughput will be necessary.

- If your primary focus is energy efficiency: Carefully balance mill speed and media charge to ensure you are not over-grinding, and use a classification system (like a hydrocyclone) to remove correctly sized particles from the circuit promptly.

By mastering these variables, you can transform the ball mill from a simple grinder into a precision tool for meeting your specific particle size requirements.

Summary Table:

| Key Factor | Effect on Product Size |

|---|---|

| Grinding Media Size | Smaller media = finer product |

| Residence Time | Longer time = finer product |

| Mill Speed | Optimized speed (65-75% critical) for efficiency |

| Wet vs. Dry Grinding | Wet grinding enables finer particles |

| Material Hardness | Harder materials require more energy |

Ready to optimize your grinding process for the perfect particle size? KINTEK specializes in precision lab equipment, including ball mills and consumables, to help you achieve consistent results from 40 microns down to the nanometer scale. Our experts can help you select the right mill and media for your specific material and throughput goals. Contact our team today to discuss your application and request a quote!

Visual Guide

Related Products

- Laboratory Single Horizontal Jar Mill

- High-Energy Omnidirectional Planetary Ball Mill Milling Machine for Laboratory

- High-Energy Omnidirectional Planetary Ball Mill Machine for Laboratory

- High Energy Planetary Ball Mill Milling Machine for Laboratory

- High Energy Planetary Ball Mill Milling Machine for Laboratory

People Also Ask

- What is the primary function of mechanical grinding equipment in PHBV production? Optimize Feedstock for Maximum Yield

- What are the advantages of ball milling? Achieve Superior Particle Size Reduction & Material Synthesis

- How does a probe-type ultrasonic homogenizer facilitate C3N4 exfoliation? Enhance Surface Area for Photocatalysis

- What is the primary technical objective of using mechanical grinding tools? Master Liquid Metal Alloying

- What is the function of a laboratory grinding mill? Achieve Precise Sample Preparation for Accurate Results

- Why is low-energy ball milling preferred during the preparation of LiPO2F2-modified sulfide solid electrolytes?

- What are the factors that affect grindability? Master Your Bead Mill for Optimal Particle Size

- What are the different types of milling in pharma? A Guide to Wet vs. Dry Milling Techniques