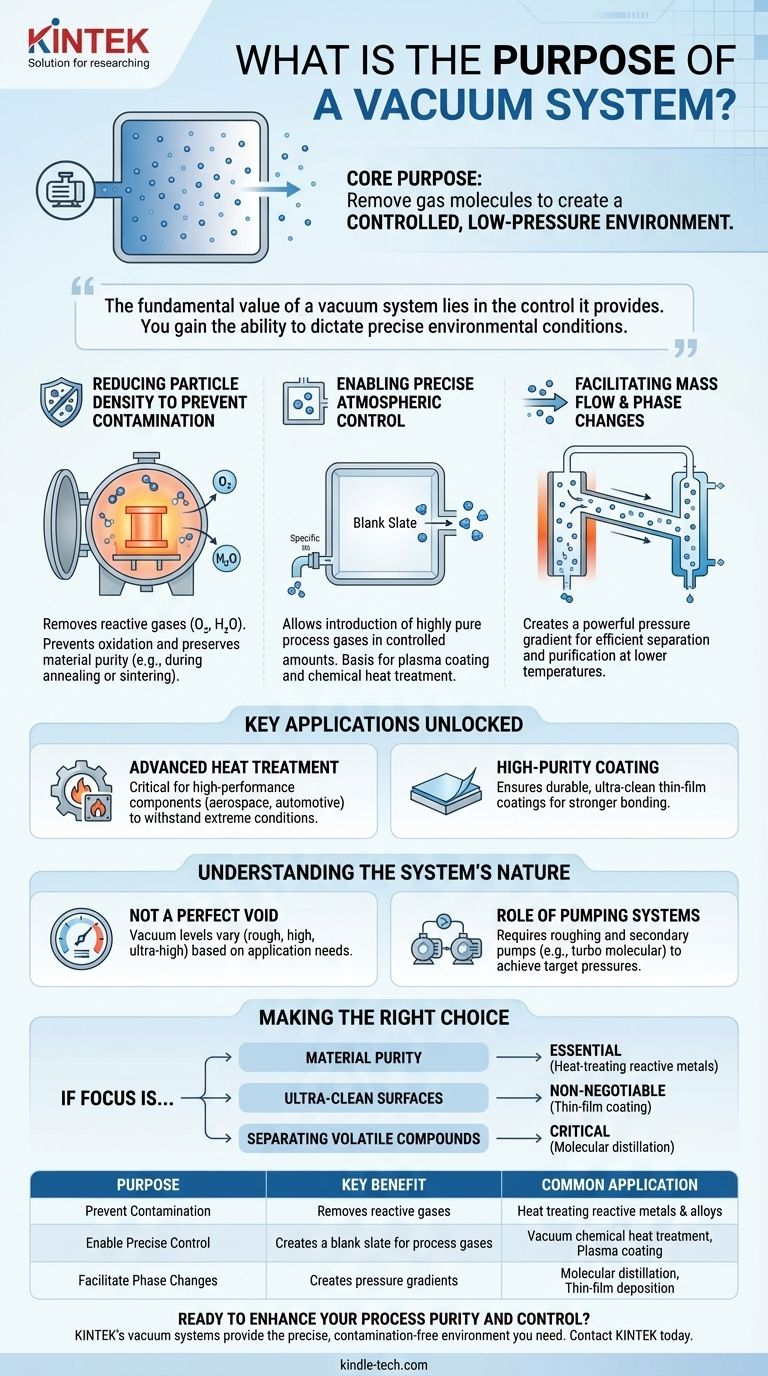

At its core, the purpose of a vacuum system is to remove gas molecules from a sealed space, creating a controlled, low-pressure environment. This deliberate removal of the atmosphere is not about creating emptiness for its own sake; it is a critical step to prevent contamination and enable a range of physical and chemical processes that are impossible to perform under normal atmospheric conditions.

The fundamental value of a vacuum system lies in the control it provides. By removing the unpredictable and reactive gases of our normal atmosphere, you gain the ability to dictate the precise environmental conditions needed to enhance material properties and enable highly sensitive processes.

The Core Functions of a Vacuum Environment

A vacuum is an active tool, not a passive state. Creating this low-pressure environment serves several distinct technical purposes that are foundational to modern manufacturing and science.

Reducing Particle Density to Prevent Contamination

The most immediate function of a vacuum is to remove the particles—primarily oxygen, nitrogen, and water vapor—that make up the air around us.

Many advanced materials, especially heat-resistant and nickel-based alloys, will react aggressively with oxygen at high temperatures. This oxidation can compromise the material's structural integrity.

By removing these reactive gases, a vacuum furnace ensures that processes like annealing or sintering happen in a pristine environment, preserving the purity and desired properties of the material.

Enabling Precise Atmospheric Control

Once the existing atmosphere is removed, the chamber becomes a blank slate.

This allows engineers to introduce specific, highly pure gases in carefully controlled amounts. This is the basis for processes like vacuum chemical heat treatment or creating a low-pressure plasma for coating applications.

Essentially, you remove the "noise" of the atmosphere to introduce a precise "signal" in the form of a chosen process gas.

Facilitating Mass Flow and Phase Changes

A vacuum creates a significant pressure gradient between the processing chamber and the vacuum pumps.

This gradient acts as a powerful driving force. For example, in wiped-film distillation (WFD), a high vacuum helps pull volatile molecules off a heated surface and onto a cold condenser.

Without the obstruction of air molecules, these volatile compounds can travel unimpeded, allowing for efficient separation and purification at temperatures far below their normal boiling points.

Key Applications Unlocked by Vacuum Systems

The control offered by a vacuum environment is not just a theoretical advantage; it is the enabling technology behind many critical industrial processes.

Advanced Heat Treatment

Vacuum furnaces are essential for treating high-performance components used in demanding sectors like aerospace.

Processes like vacuum quenching, annealing, and sintering are performed in a contamination-free environment. This allows parts like engine components and exhausts to better withstand extreme heat and mechanical stress.

High-Purity Coating

Creating durable, thin-film coatings requires an ultra-clean surface and environment.

A vacuum ensures that no stray particles interfere with the deposition process, allowing for a stronger, more uniform bond between the coating material and the substrate.

Understanding the System's Nature

While incredibly powerful, a vacuum system is not a perfect or simple solution. Understanding its practical nature is key to using it effectively.

It Is Not a Perfect Void

Different applications require different levels of vacuum. A "rough vacuum" may be sufficient for some processes, while others demand a "high vacuum" or "ultra-high vacuum."

Achieving higher levels of vacuum requires more sophisticated and expensive equipment.

The Role of Pumping Systems

Creating and maintaining a vacuum requires a system of pumps.

Typically, a roughing vacuum pump removes the bulk of the air, and a secondary pump, such as a turbo molecular pump, takes over to achieve the much lower pressures needed for high-vacuum applications.

Making the Right Choice for Your Goal

Deciding to use a vacuum system depends entirely on the sensitivity of your process to the ambient atmosphere.

- If your primary focus is material purity and preventing oxidation: A vacuum system is essential for heat-treating reactive metals or high-performance alloys.

- If your primary focus is creating ultra-clean surfaces for coating: A high-vacuum environment is non-negotiable to ensure the quality and adhesion of deposited thin films.

- If your primary focus is separating volatile compounds at low temperatures: A vacuum system is critical for creating the pressure gradient needed for processes like molecular distillation.

Ultimately, a vacuum system is a tool for achieving a level of environmental control that is simply unattainable at atmospheric pressure.

Summary Table:

| Purpose | Key Benefit | Common Application |

|---|---|---|

| Prevent Contamination | Removes reactive gases (O₂, H₂O) | Heat treating reactive metals & alloys |

| Enable Precise Control | Creates a blank slate for specific process gases | Vacuum chemical heat treatment, Plasma coating |

| Facilitate Phase Changes | Creates pressure gradients for efficient separation | Molecular distillation, Thin-film deposition |

Ready to enhance your process purity and control?

KINTEK's vacuum systems are engineered to provide the precise, contamination-free environment your lab or production line requires. Whether you are heat-treating high-performance alloys, developing thin-film coatings, or purifying sensitive compounds, our expertise in lab equipment ensures you get a solution tailored to your specific vacuum needs.

Contact KINTEL today to discuss how our vacuum technology can unlock your next breakthrough.

Visual Guide

Related Products

- Variable Speed Peristaltic Pump

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Laboratory Sterilizer Lab Autoclave Pulse Vacuum Lifting Sterilizer

- Benchtop Laboratory Vacuum Freeze Dryer

- Vacuum Hot Press Furnace Machine for Lamination and Heating

People Also Ask

- What are the benefits of a vacuum furnace? Achieve Superior Material Purity and Process Control

- How is sintering temperature determined? Master the balance between density and distortion.

- How does the cooling rate control of a furnace influence slow-cooled solid-state electrolytes? Achieve Crystal Perfection

- What are the benefits of vacuum annealing? Achieve Pristine, Oxide-Free Parts with Superior Material Properties

- What are the applications of vacuum deposition? Create High-Performance Coatings for Your Products

- What is the role of a laboratory high-temperature resistance furnace in TSR testing? Quantifying Material Durability

- What are the different types of batch furnace? Find the Right Fit for Your Heat Treating Process

- What is the specific role of a vacuum furnace in ZnS ceramic fabrication? Achieve Optical-Grade Material Purity